Potential Design Changes and Garage Work – November/December 2022

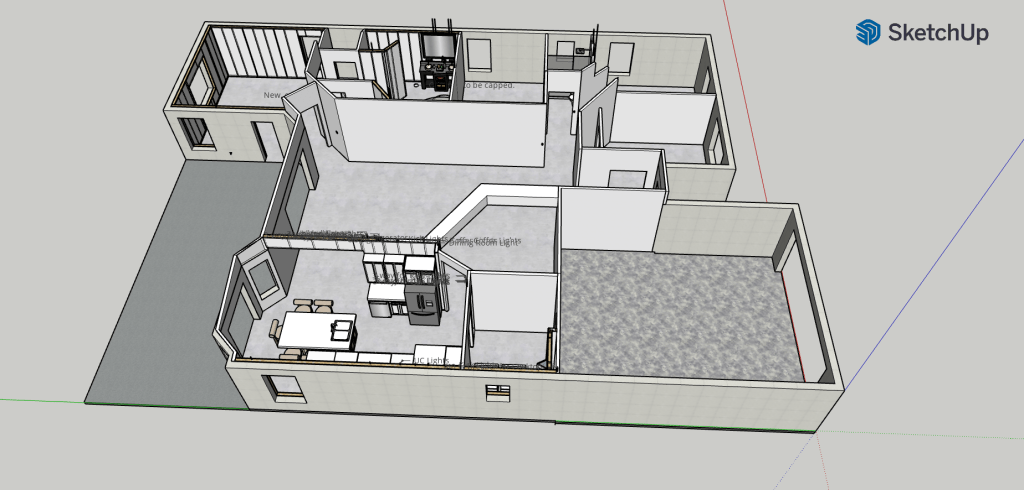

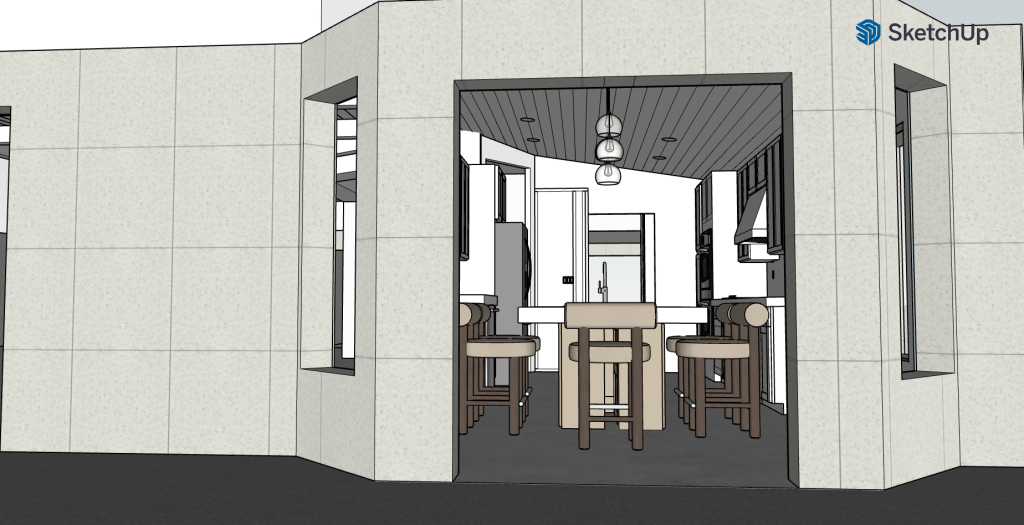

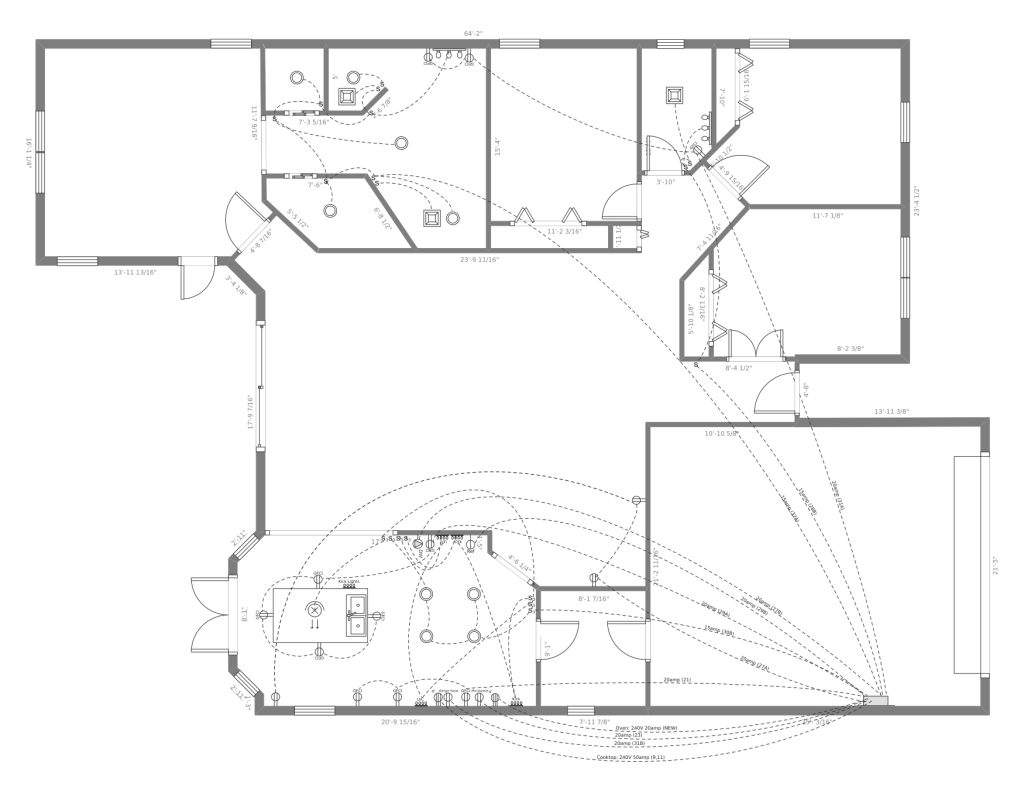

As mentioned at the end of the last post, I met with Jennifer, my designer. Among the usual business of selecting materials and such, a new idea for the kitchen came up. She was struggling a bit with how I wanted to have the island centered and facing the french doors. She was concerned about the limited work space and ergonomics. While meeting with her at ProSource, we were in a display area with a really nice island setup. I mentioned it and she said we could do that if we removed the wall separating the kitchen and great room. This was not something I had considered. I had always had my heart set on standing at the sink and facing the french doors and the view that presented. I also liked the idea of having a bit of separation between the two rooms. But I did understand her concerns. So when she presented this idea, coupled with the showroom kitchen we were standing in, I was intrigued. So she will be providing me with two designs: one with the original plan, and another with the new idea she is proposing. More on that when it materializes.

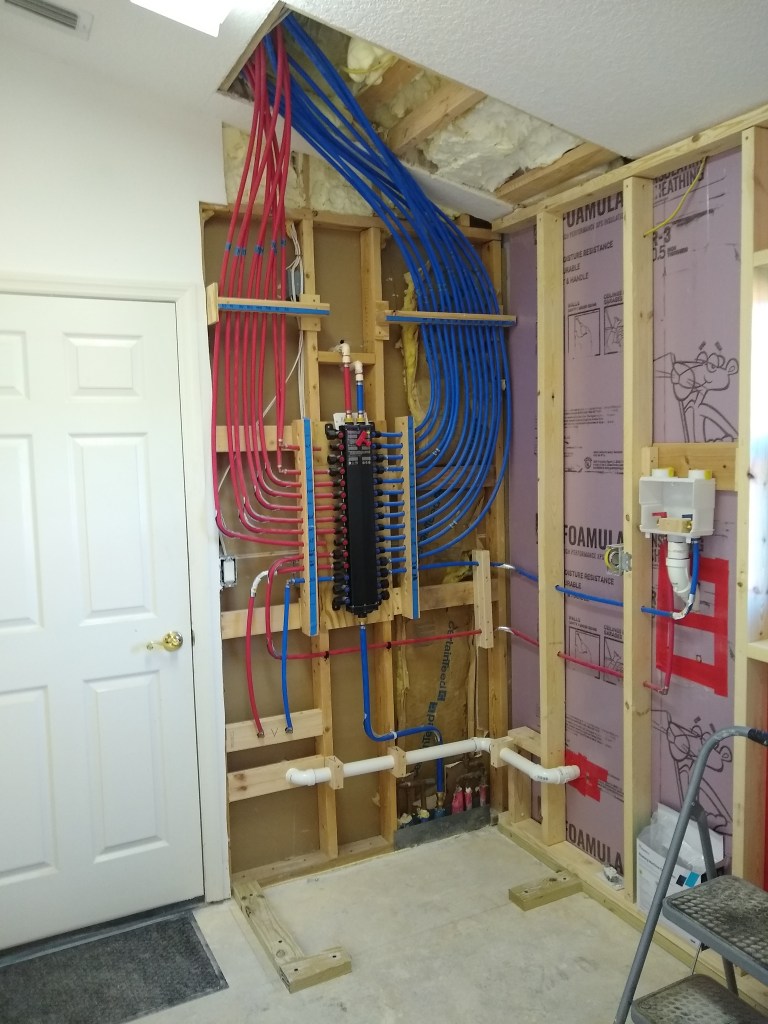

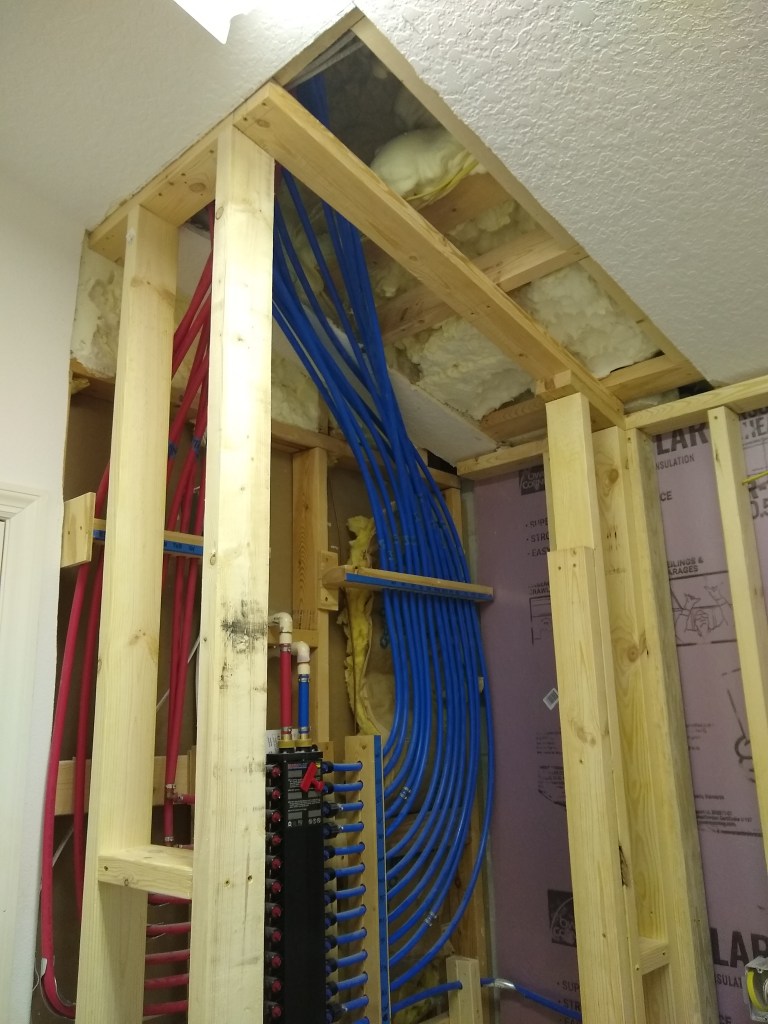

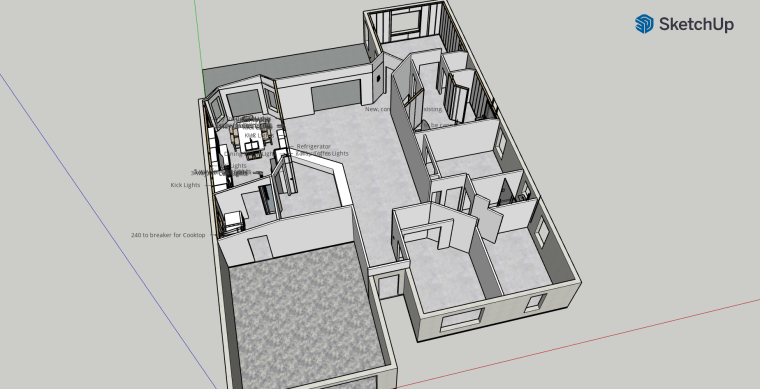

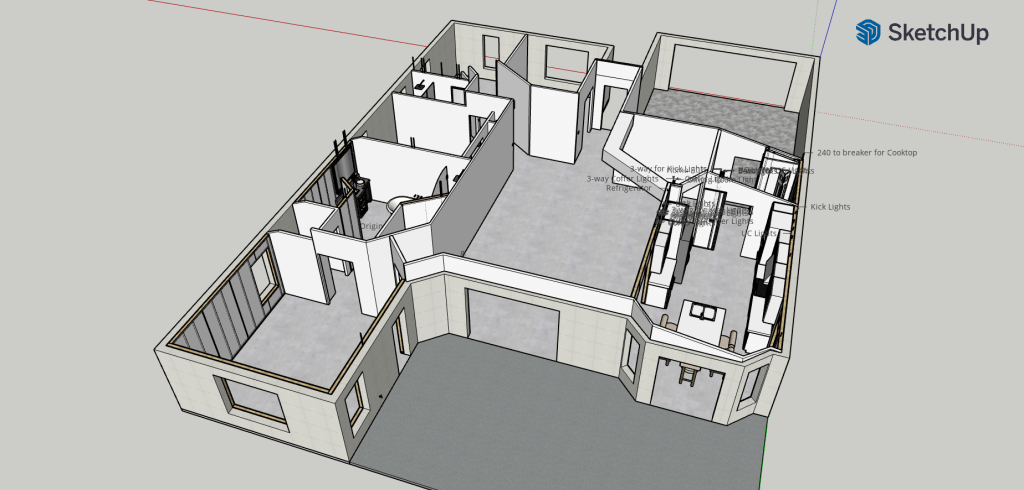

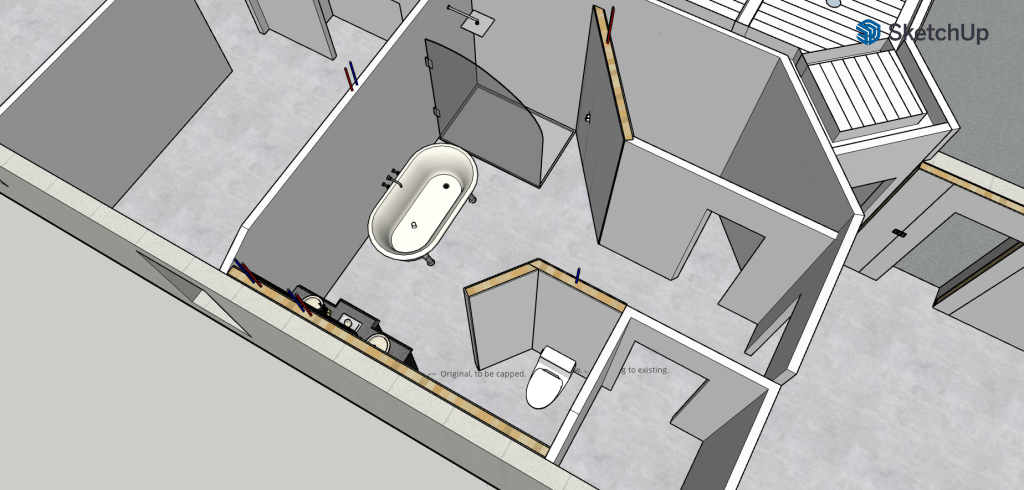

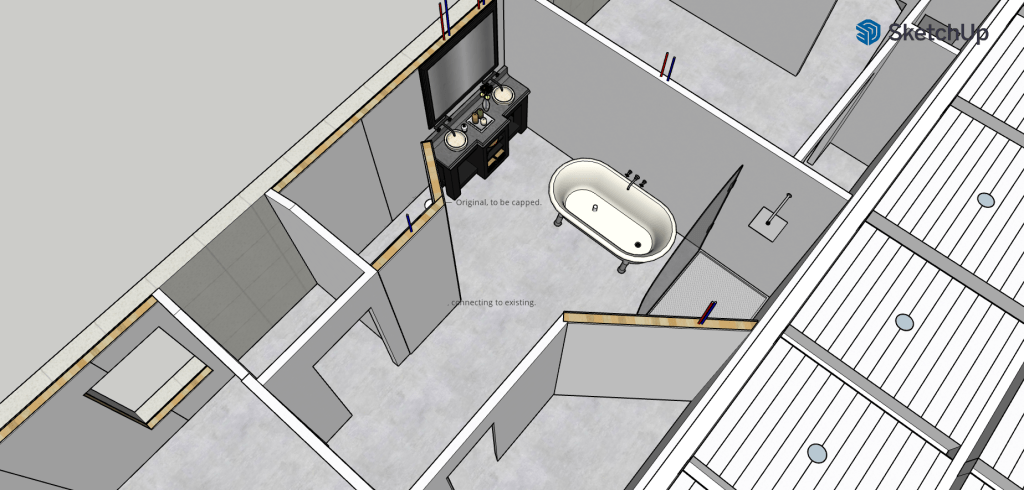

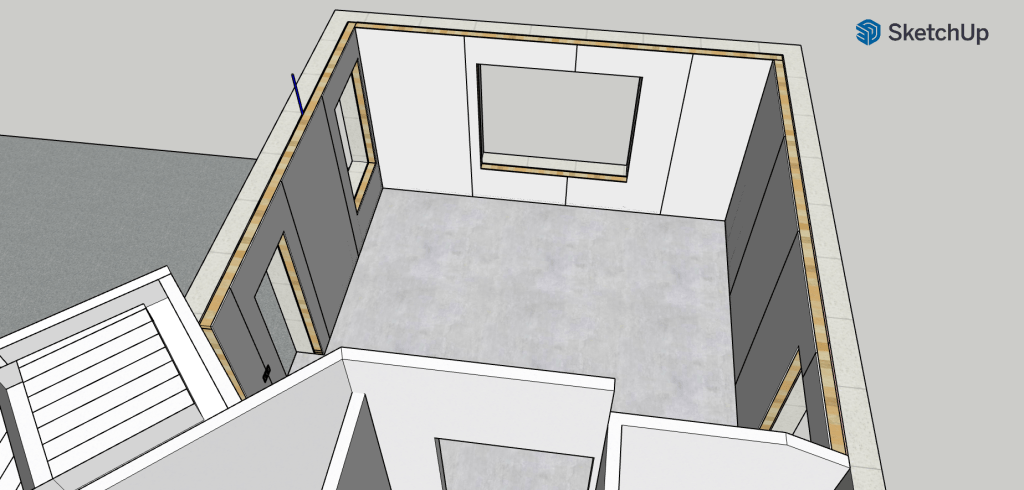

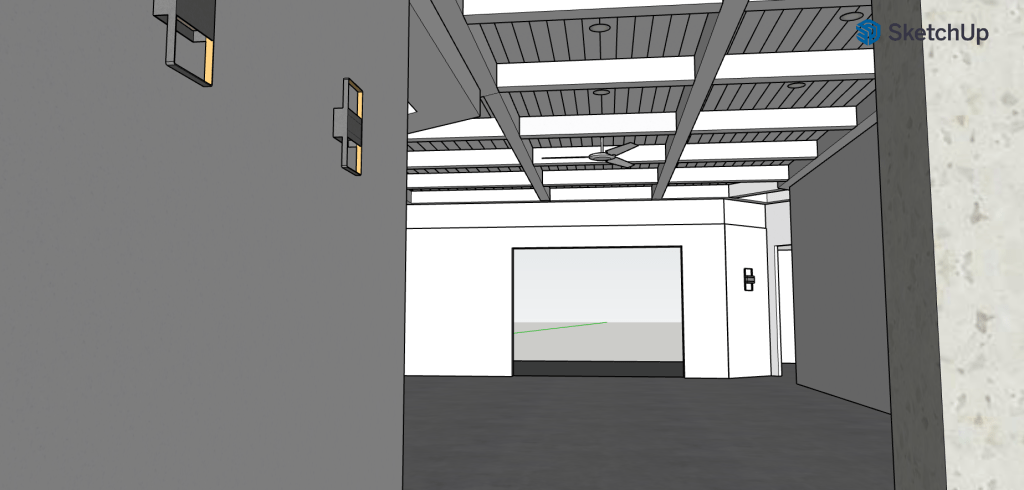

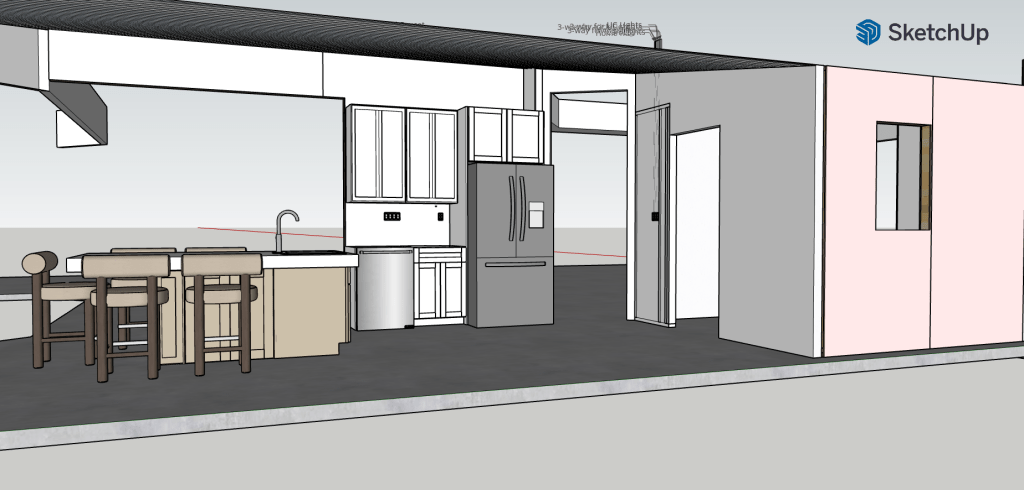

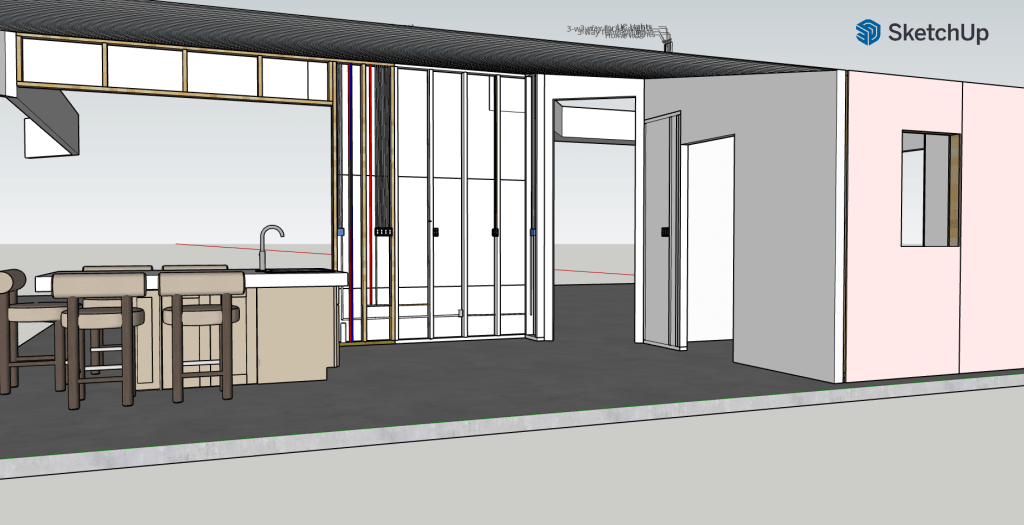

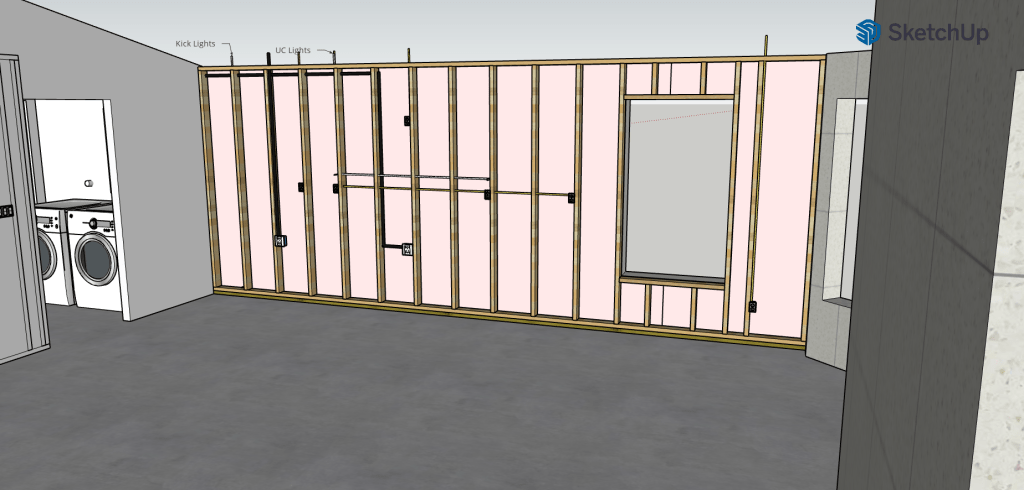

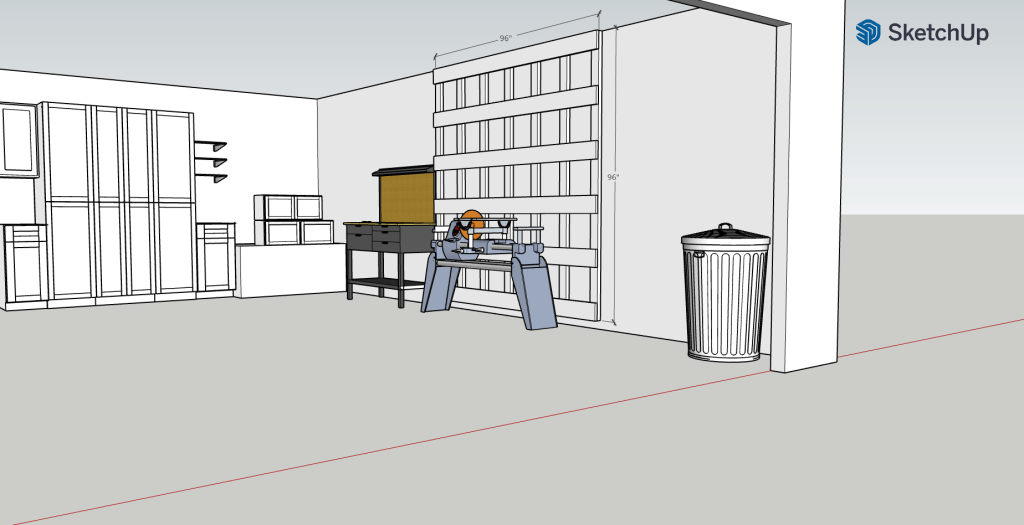

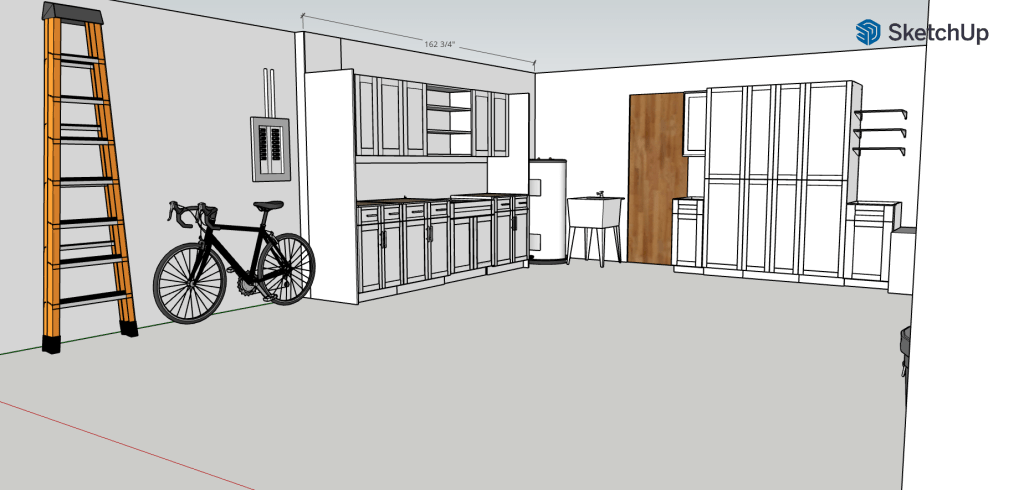

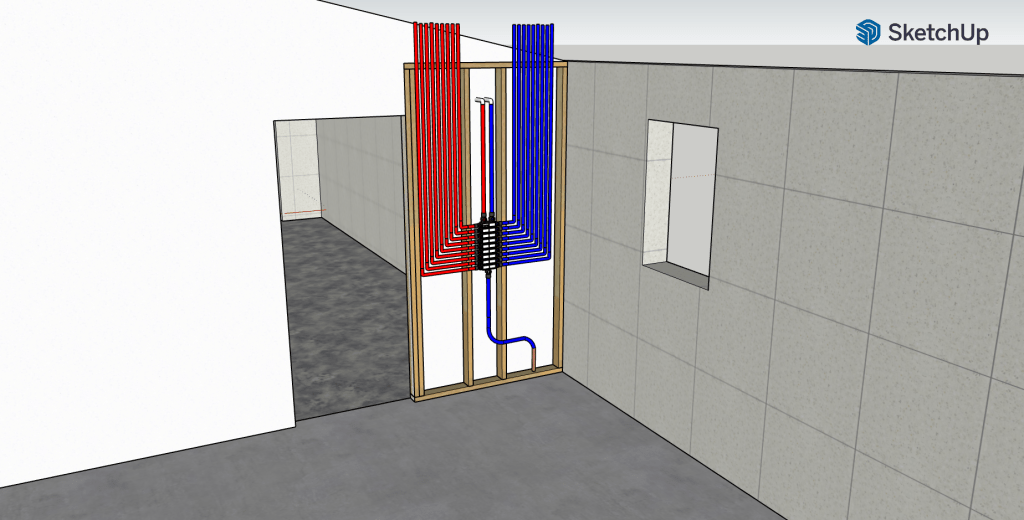

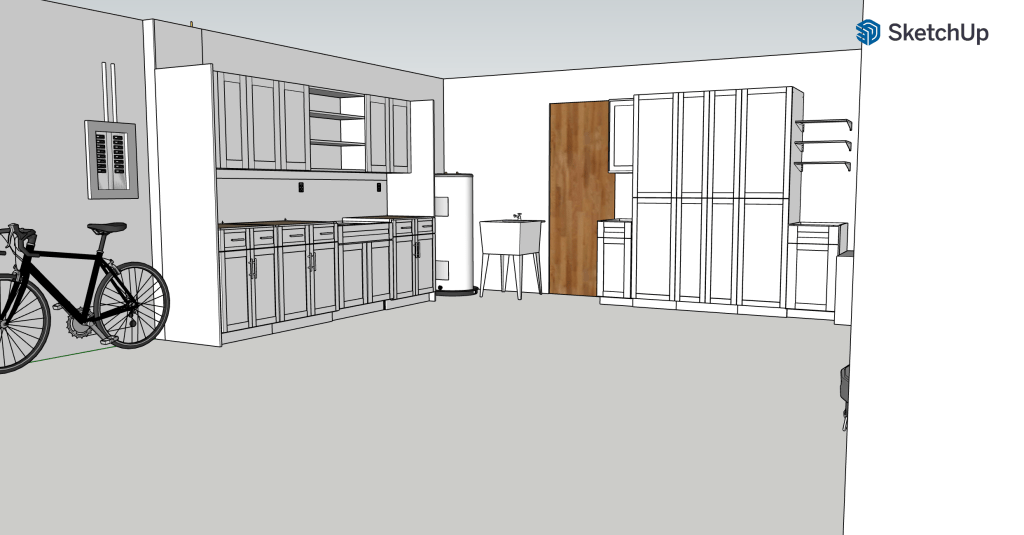

In the meantime, I shifted my attention to the garage, because it is not dependent on Jennifer’s work. Here is how the garage is to look (I’m using the free version of SketchUp, so I’m stuck with the SketchUp label you see in the upper right corner).

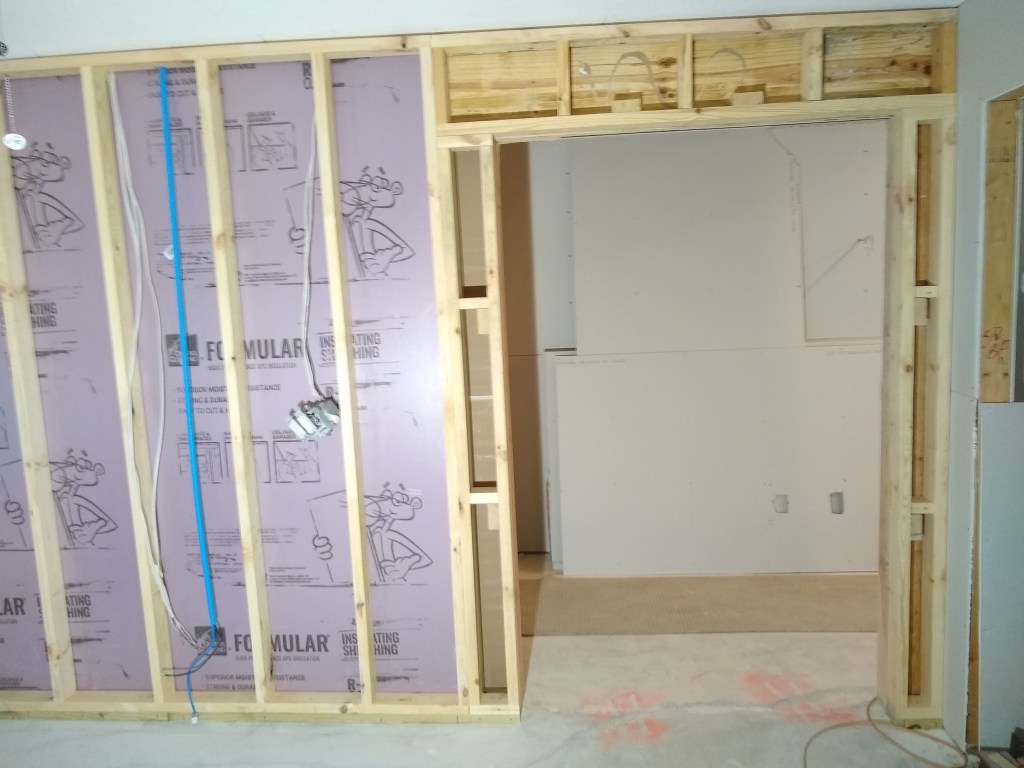

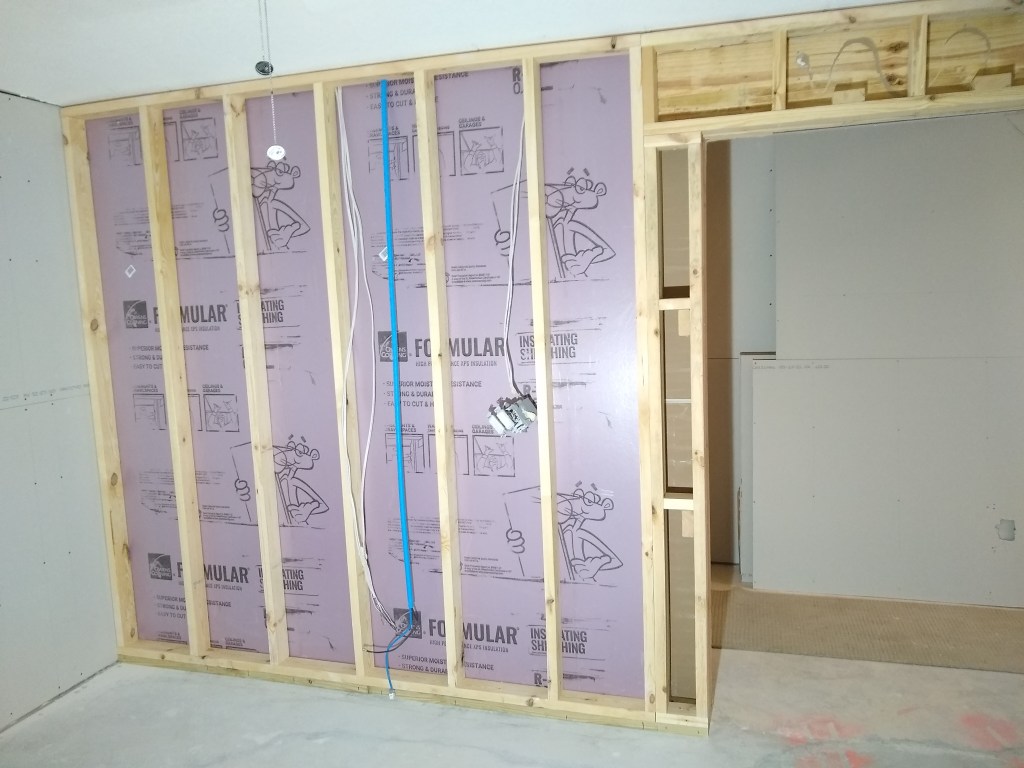

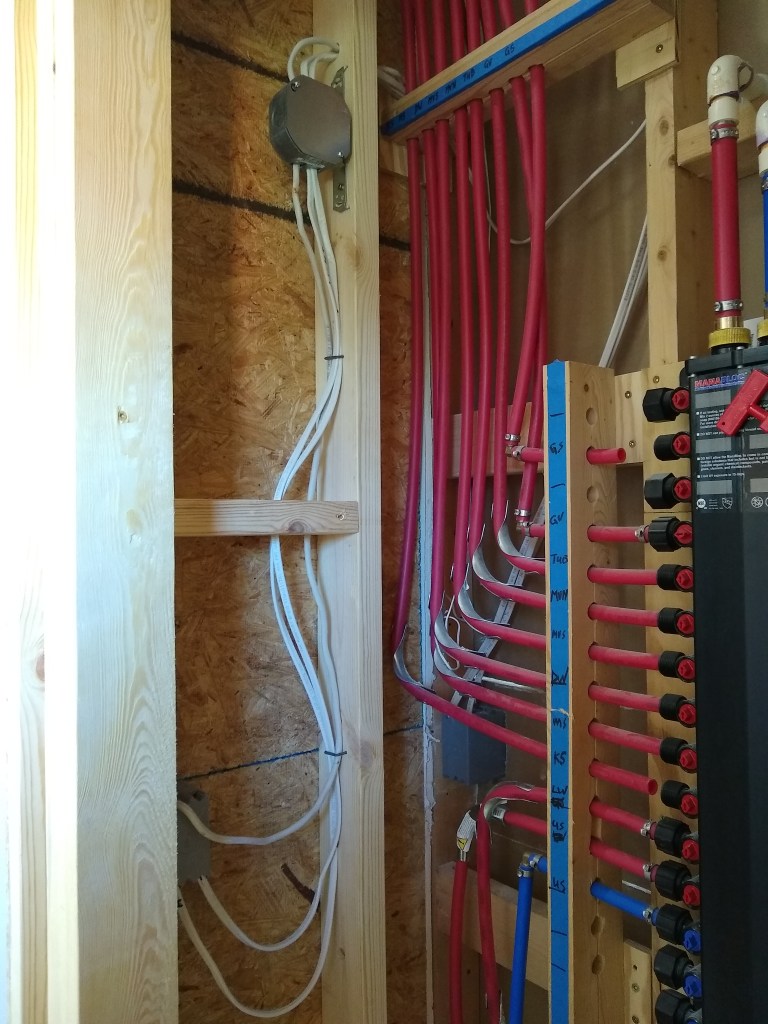

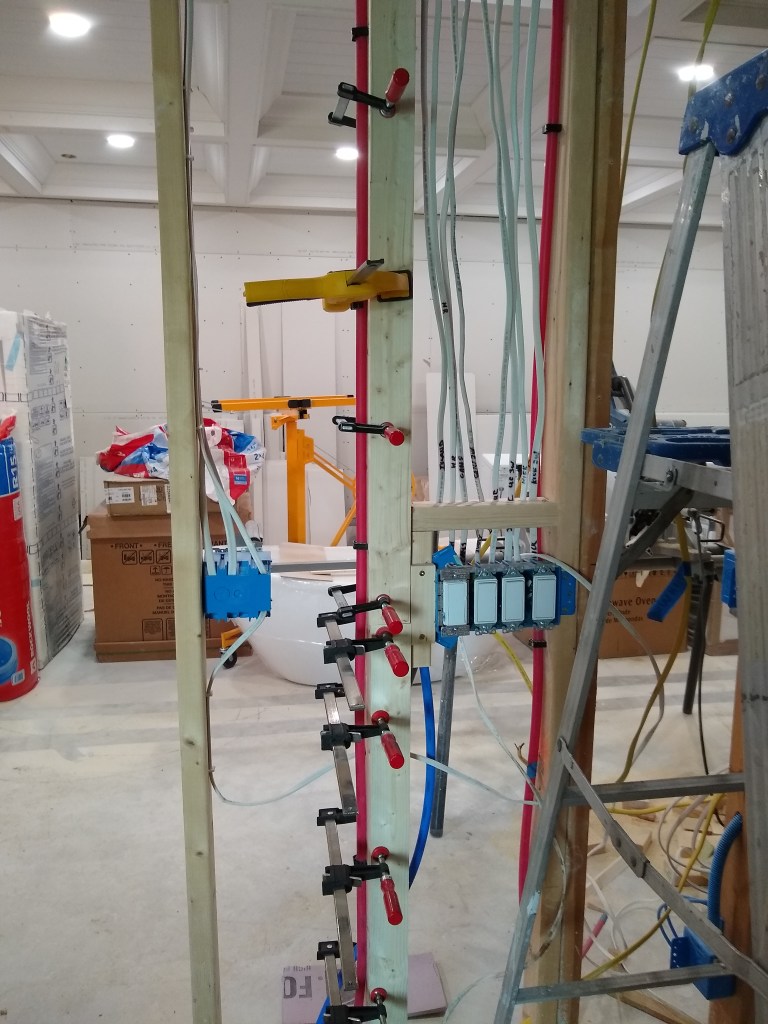

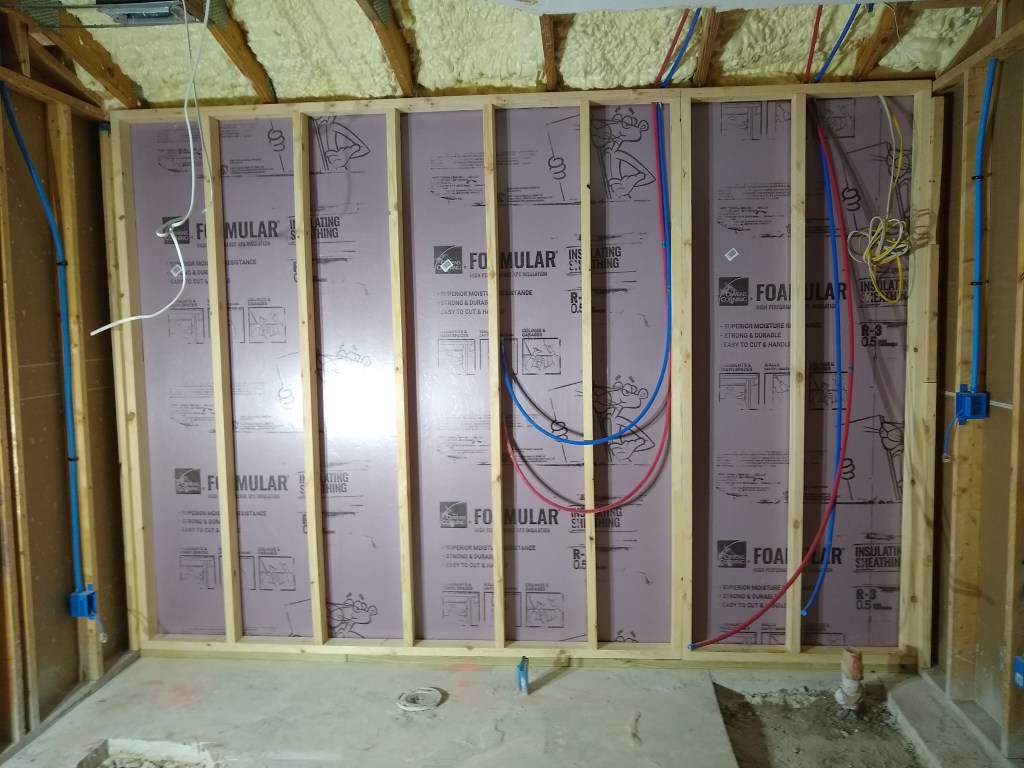

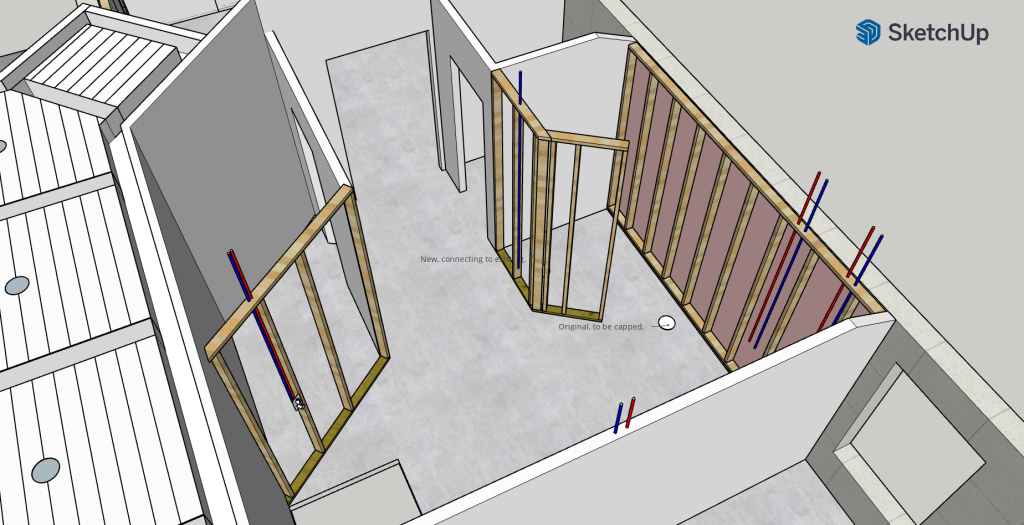

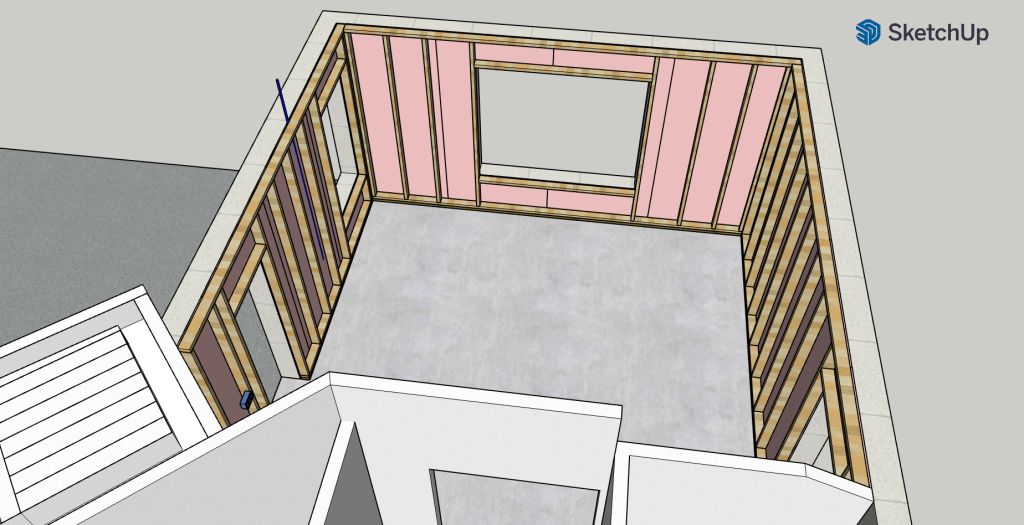

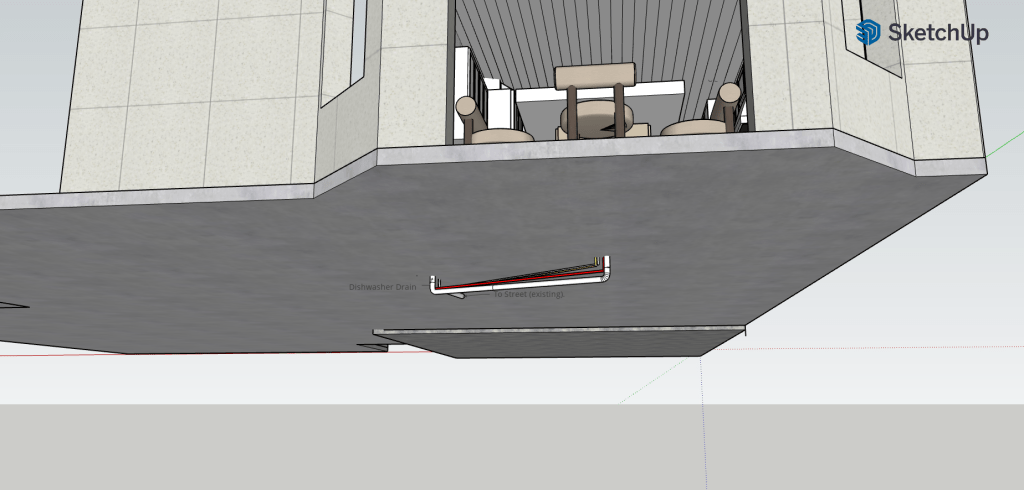

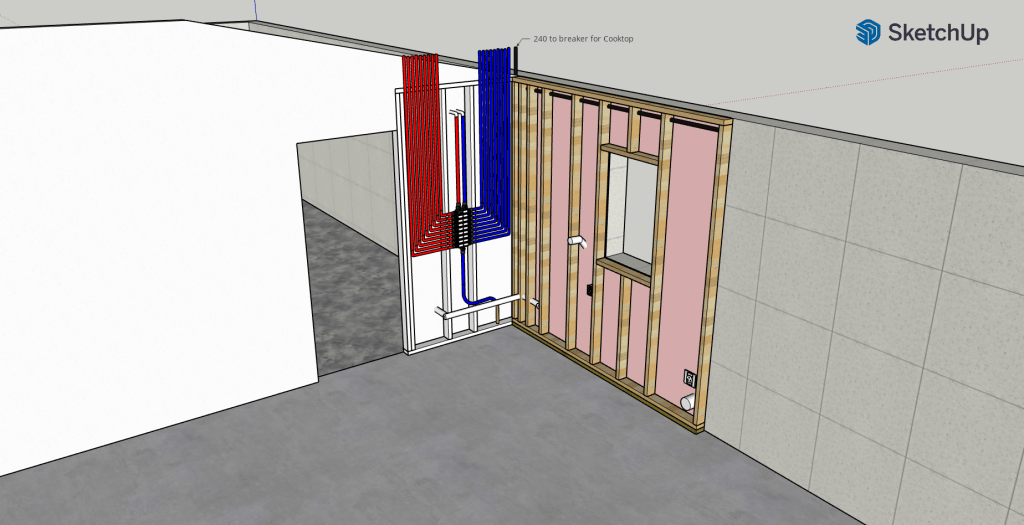

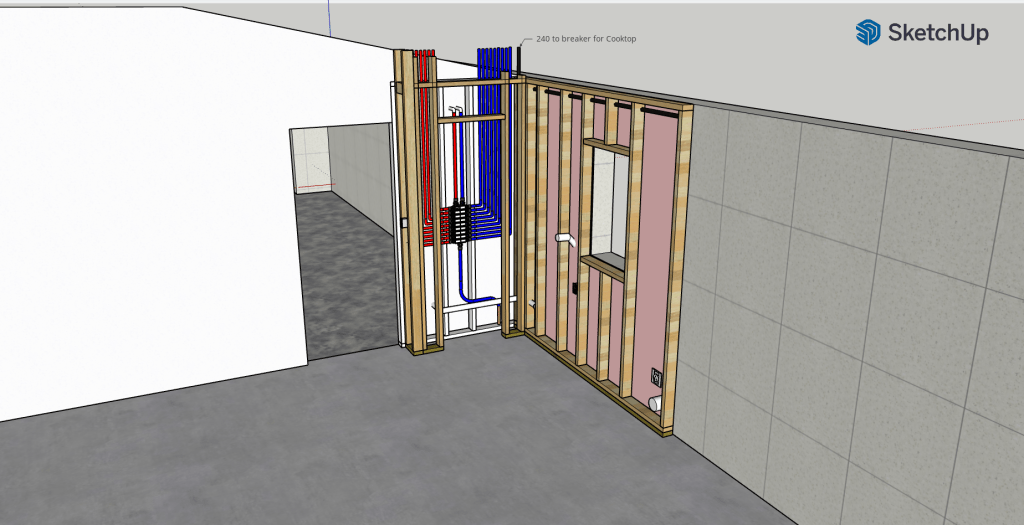

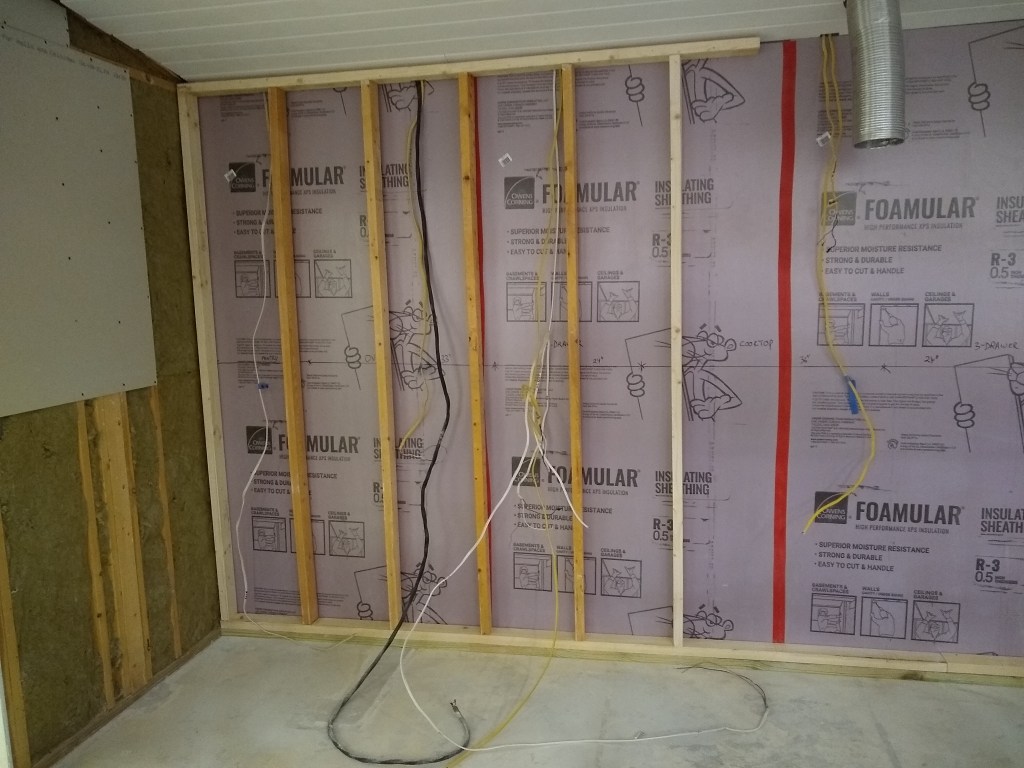

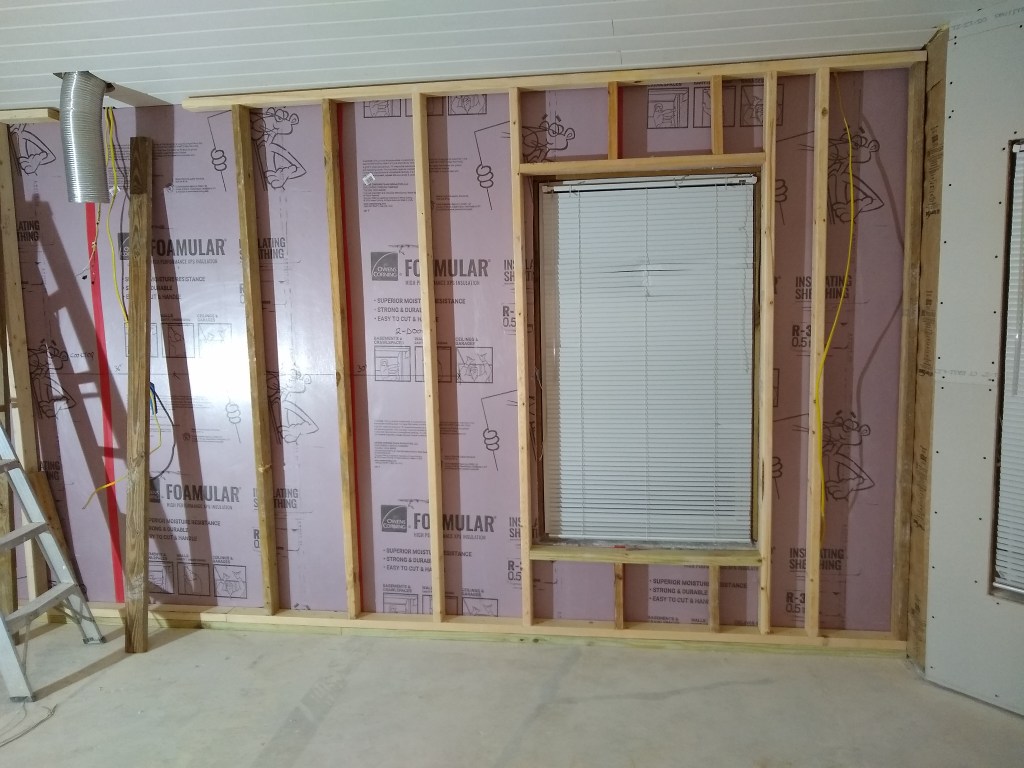

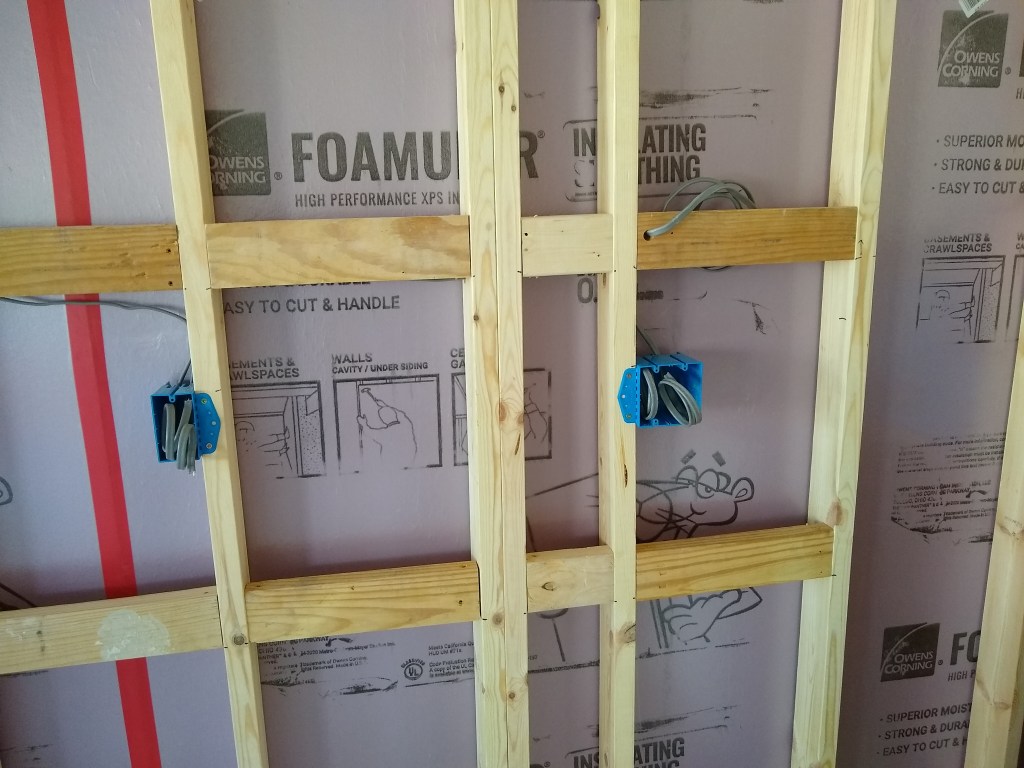

I had already framed the east wall of the garage and run wires for the electrical. But the back wall required some work to add two new outlets on either side of the tall cabinets that will be installed there. There was a single outlet on that wall, which would be blocked by the tall cabinets. So I wanted to replace it with an outlet above each of the base cabinets that flank them. To do this I had to remove the drywall so I could run the wire. Here’s what I came up with.

The source power comes down from above. It feeds the outlet on the left, then connects to the outlet on the right, then back up to the outlet up top where it continues to provide power to outlets on the adjacent wall on the right. The outlet up high was originally at the same level as the others but in the middle of the wall, therefore it would be blocked by the tall cabinets that will be placed there. So I decided to move it up above the tall cabinets and run the wires from there. Originally I figured I would just make it a junction box, but decided it might be handy to have an outlet above the tall cabinets at some point. Either way, a junction was needed and junctions cannot be inaccessible (by code), so even though it is up high, it is accessible.

After sorting that out, I proceeded to add blocking, which is what the cabinets will be secured to. Strictly speaking, you don’t have to add blocking. You can just use the existing framing members, but that provides a much smaller target, so I opted for the blocking.

Another thing I did was replace the rightmost 1-gang outlet box on the east wall with a 2-gang box that would provide an outlet and a switch for under counter lighting. I thought that would come in handy and would be good practice for when I do it in the kitchen.

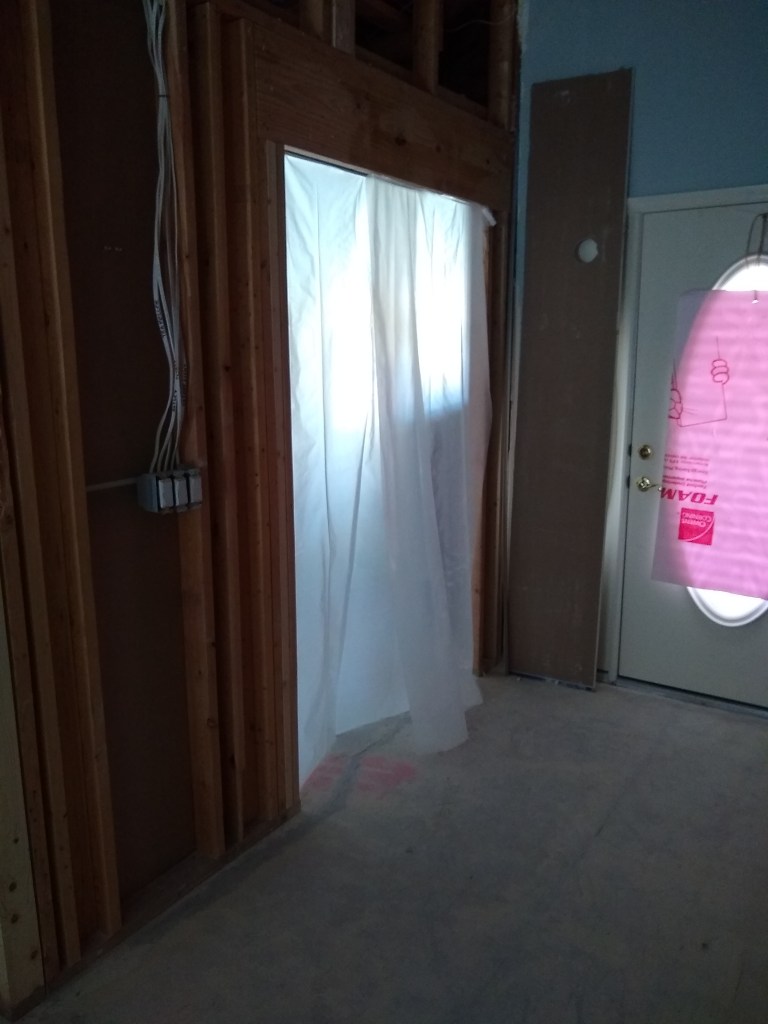

Before putting up drywall, I needed to get an electrical and framing inspection. This was scheduled and successful. My first time! I’m now a man of the world. One of the benefits of having passed an inspection is that each successful inspection extends the expiration date of the permit by 6 months. My permit was due to expire in February, so I’m good for a while now.

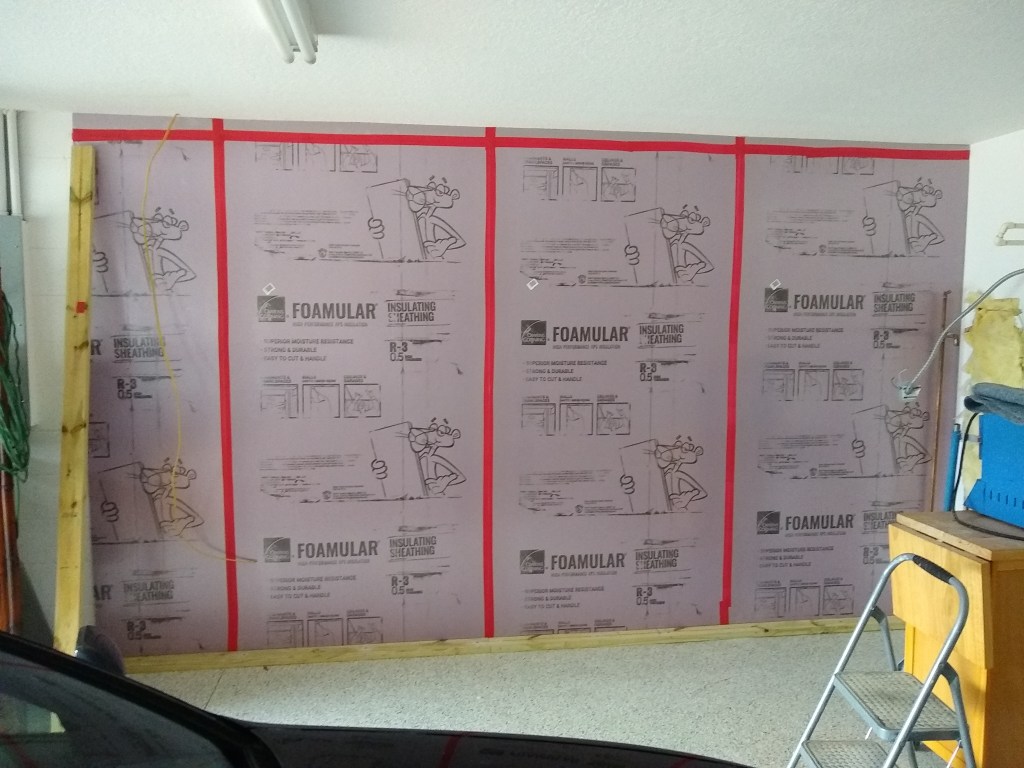

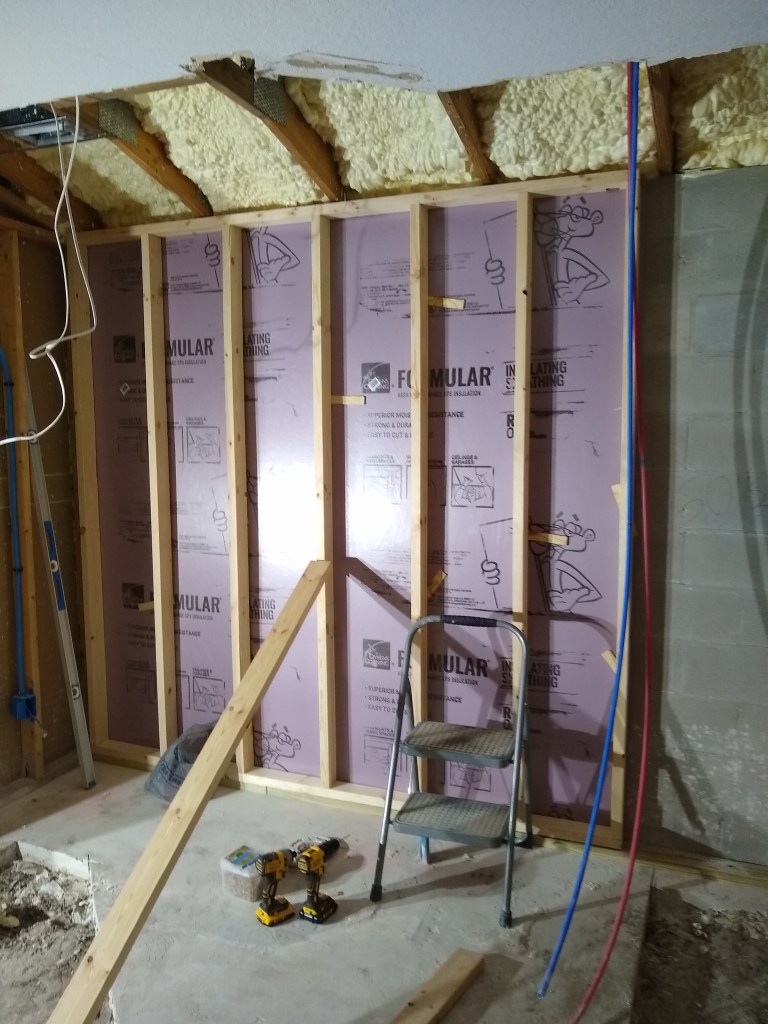

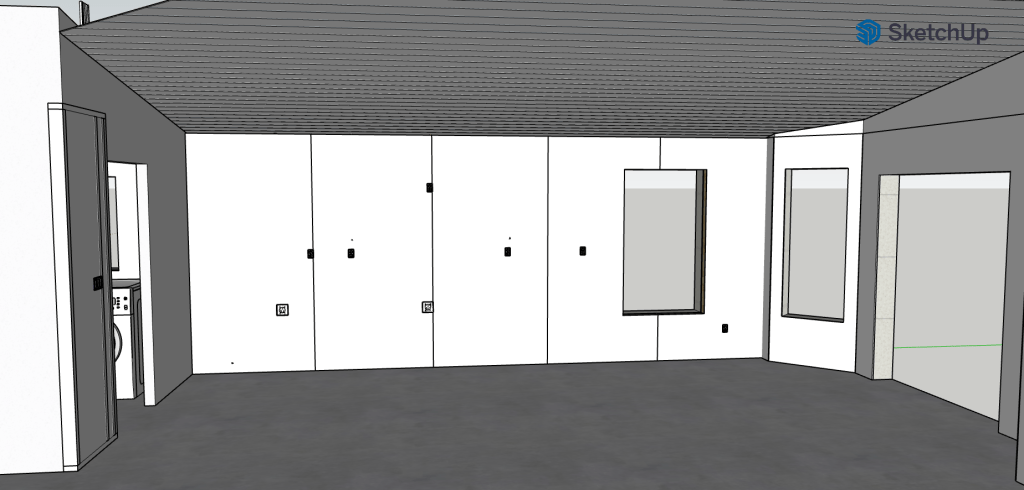

With the inspection done, I proceeded to add insulation and start hanging drywall.

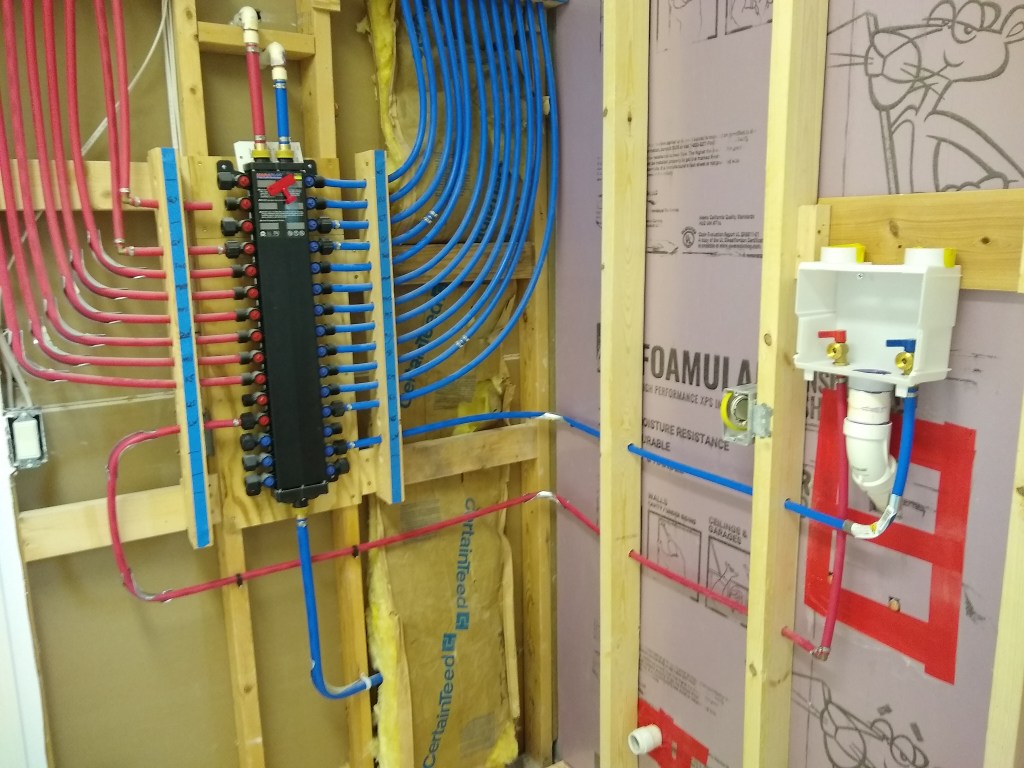

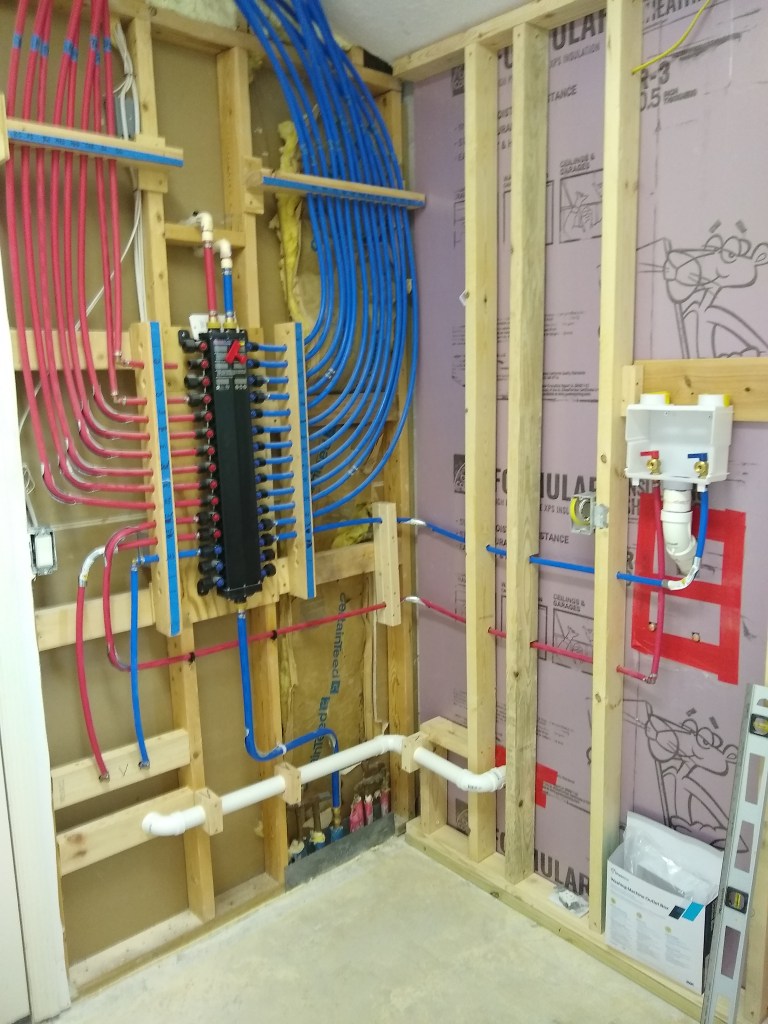

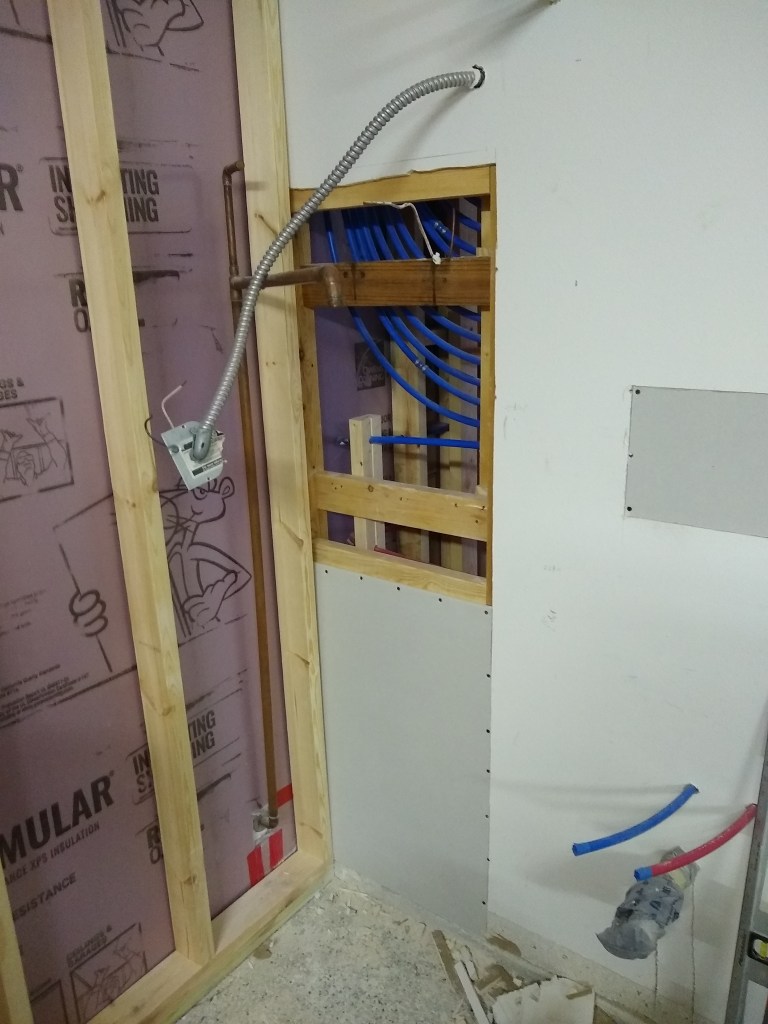

If you look closely at the upper right corner, you’ll notice a wire extending from a junction box. This is 240 volt line that feeds the hot water heater. It originally entered the garage from the adjacent wall. Now that I have framed the east wall of the garage, it is a more direct route to have it enter from there. So I moved it and now it is no longer within the plumbing closet in the laundry room.

I should say something about the insulation. It may seem a bit silly to insulate part of a wall given that the rest of the wall (and the opposing wall, not to mention the garage door) is not insulated. I decided to add it because I may want to insulate the entire garage in the future. Of course, the back wall must be insulated because it separates the garage from the inside of the house.

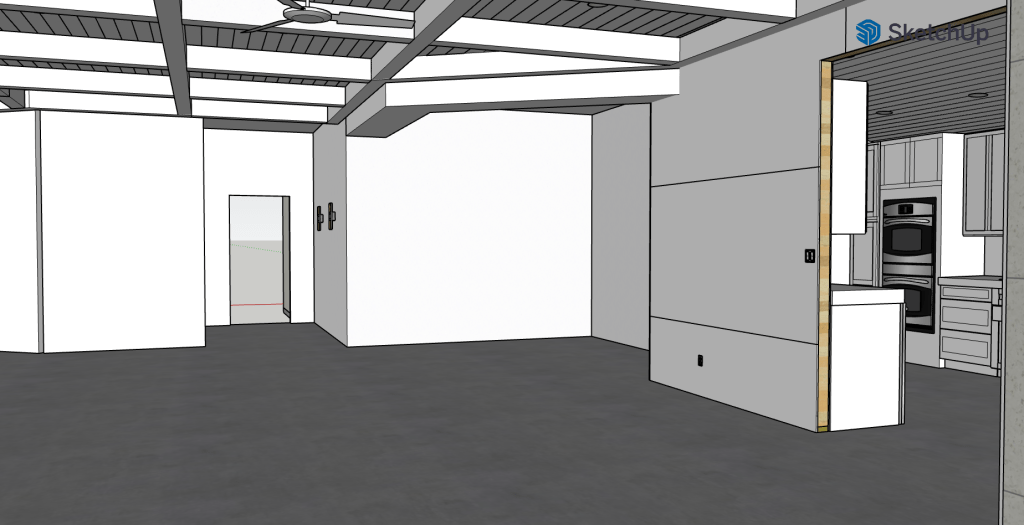

And here are some images of the walls with the drywall hung.

Before I can begin taping and mudding, another inspection for the drywall was needed. I scheduled it and there were no issues. With that inspection complete, I can now proceed without the need for any further inspections for the garage work. So I got busy taping.

It is questionable whether I needed to do any more mudding at this point because most of this wall space will be covered with cabinets, but I decided to continue, mostly to experiment. In my first experience doing drywall (guest bedroom), I used a different kind of mud for my final (skim) coat. It was a lighter mud called Plus 3, and I liked it. It spread well and sanded well. So this time I wanted to try using an all-purpose mud to see how it worked for skimming. I watered it down to make it easier to use, but in the end, I think I preferred the Plus 3 for a final coat. I only did a skim coat on the back wall. I didn’t have enough mud to skim the east wall, and since it was not needed I wasn’t going to buy more. Unfortunately, I forgot to take any pics of the process and only thought about it as I was priming the east wall, so I don’t have an image of the skim coated back wall. Here is a pic of the east wall in the process of being primed.

Here are images of the walls after the primer (Kilz 2) was applied.

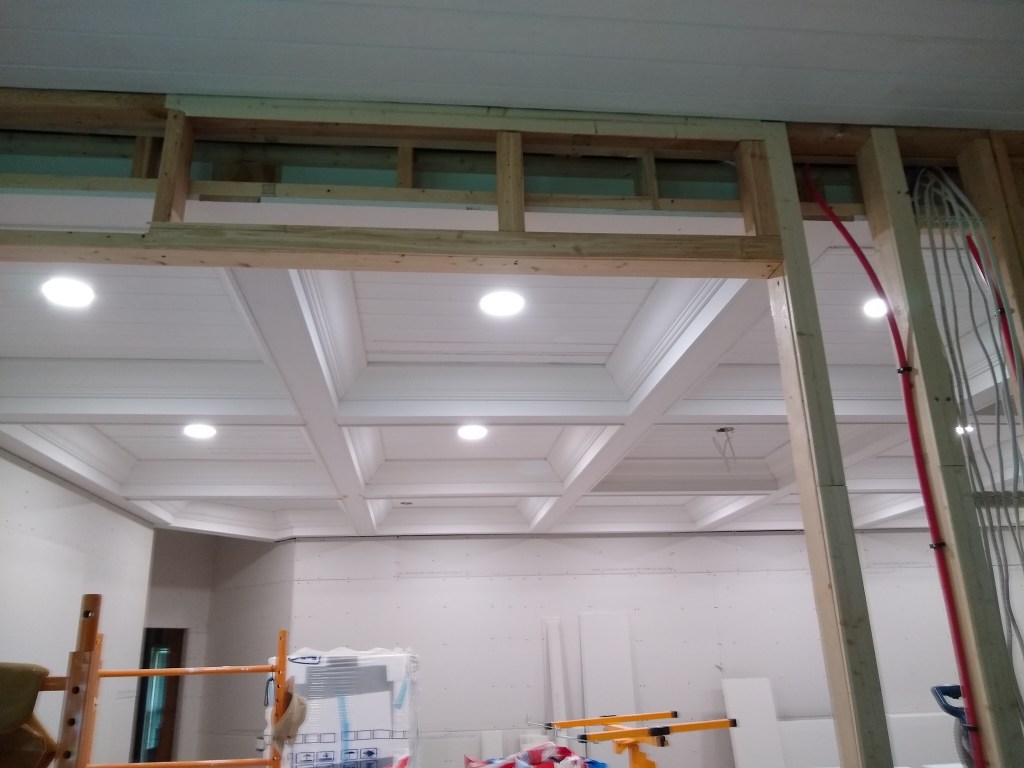

One could install the cabinets at this point, but I decided to add a top coat of paint before doing that since it will be much easier with the walls bare (i.e., no cabinets in the way). I also wanted to put up a trim piece between the east wall and ceiling. Here is the result.

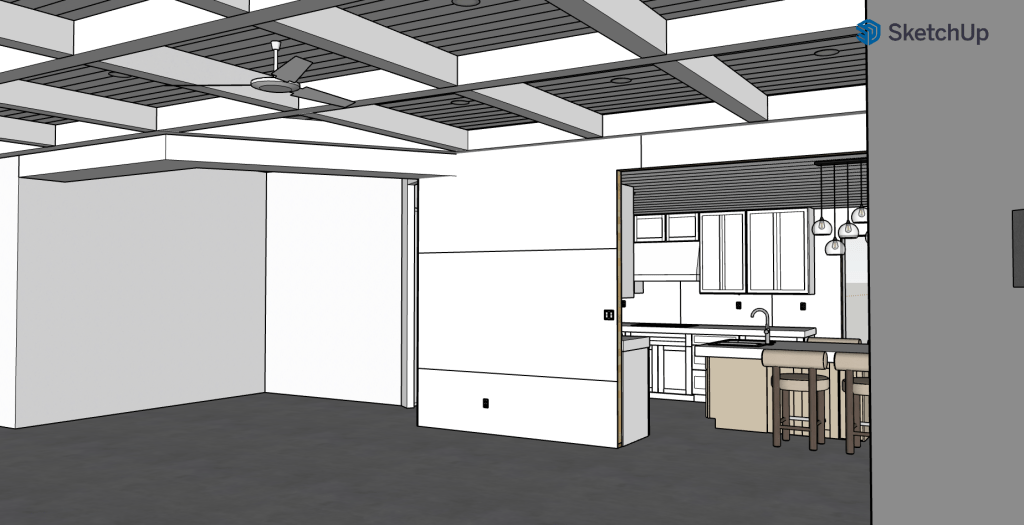

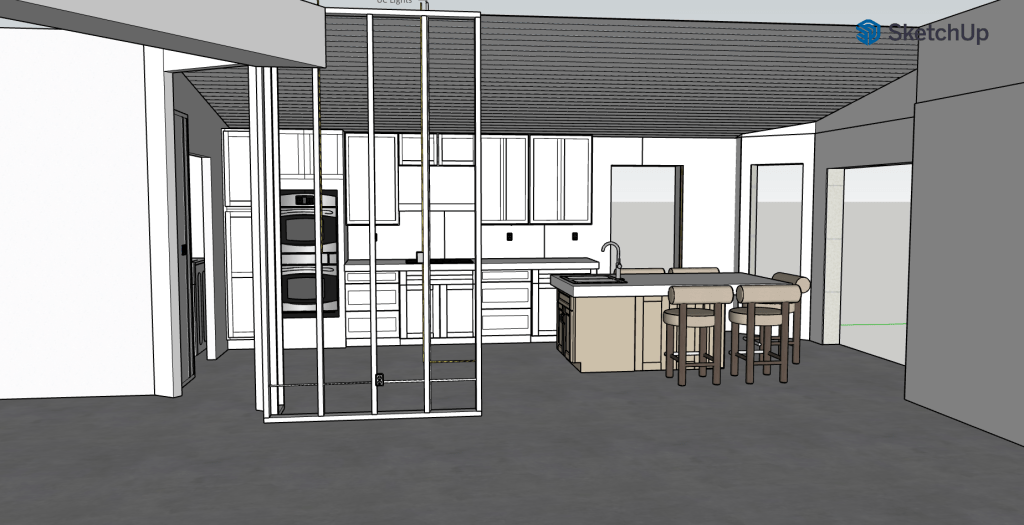

Cabinet installation along the east wall was next. It’s common to start by installing the upper cabinets first so that the base cabinets are not in the way. Often one will put up a ledger board to support the wall cabinets as they are positioned, especially if working on your own, as I do. But I saw a video on YouTube where the guy installed the base cabinets first and used a makeshift bench to support the wall cabinets. I will elaborate on this in a moment.

Installing the base cabinets required quite a bit of shimming, since garage floors are sloped for drainage from the back of the garage to the front. I started by using my laser level to establish where the top of the base cabinets needed to be. Using a laser level is a luxury, and I was happy to benefit from it. The first cabinet to be installed was the one closest to the front of the garage (nearest cabinet in the image above), since I wanted it to line up with the edge of the newly framed wall. It required a pretty big shim to elevate it to level, so I cut my own and used my thickness planer to get it just right. You can see how the gap below the cabinets decreases as you move toward the back of the garage. This will eventually be covered with a continuous strip along the kick plate.

I managed to install all the base cabinets in one afternoon, albeit a long afternoon. Having never done this before, I was pretty happy with that. The next day, I started on the wall cabinets.

As mentioned above, I adopted an approach to installing the wall cabinets from a video I saw on YouTube. What appealed to me about the approach was that it was well suited for a single person installation. With the base cabinets installed, all the leveling work is done and you can benefit from that by simply referencing off it. The idea is to construct a simple bench (shown above) out of whatever pieces you have lying around and make it tall enough to reach the bottom of the wall cabinet with about an eighth of an inch to spare. You then place the wall cabinet on top of the bench and use shims to make up the difference to get the cabinet exactly where you want it. Once the cabinet is secured, you remove the shims, allowing the bench to be easily extracted. This worked like a charm and I was so pleased I came upon it. Putting up the wall cabinets was a breeze using this approach.

The wire hanging down beneath the upper cabinet will be used for under counter lighting. The gap between the wall cabinets is a consequence of these cabinets being originally intended for my other house before I sold it (without actually replacing the kitchen). In that house, the base cabinet for the sink did not have a cabinet above it. So I decided to use that space for open shelving.

To create the open shelving, I had to improvise a bit. I had some cabinet pieces I wasn’t sure what to do with. One piece was a side panel with a return (the thick bit below the bottom shelf) that was intended for the dishwasher at the other house. I cut the panel in half and used the return as a facing to match the lower rail of the adjacent cabinets, forming the lower shelf. I think it looks great and has the added benefit of concealing the under counter lighting in the same way the cabinets do. Nice!

The two upper shelves were constructed from a refrigerator panel I decided not to use. I originally intended to use the two refrigerator panels to flank either side of this bank of cabinets (see image at the beginning of this post), but decided it looked better and would function better without them. So I cut what I needed from one of them. I also decided not to add a piece at the top to join the cabinets, as is shown in the SketchUp drawing above. That would limit what I could put on the top shelf. So far, I’m very happy with the way this looks.

I will add a butcher block countertop to give it a workbench look. I will attend to this in early January, as I will be away over the holidays. I also intend to add some sort of slat wall system as a backsplash so that I can hang things on it and move them around as I see fit. But I won’t get to that until it makes sense. I would normally move directly to installing the cabinets on the back wall of the garage, but I am still missing a cabinet. Hopefully that will arrive some time in January and I can continue.

As for the design updates from Jennifer, she just sent me two options for the kitchen. I really like one of them and will be meeting her in a couple of days to go over it. It will probably still be a while before I am able to move forward on the interior of the house, even after we are settled on the design. If the kitchen layout changes, as I expect it will, I will probably have to update the permits. But I still have plenty to do in the garage, so I will continue with that in the meantime.

That’s all for this post as I will be leaving shortly for Christmas vacation. Happy holidays!