Master Bathroom – September 2024

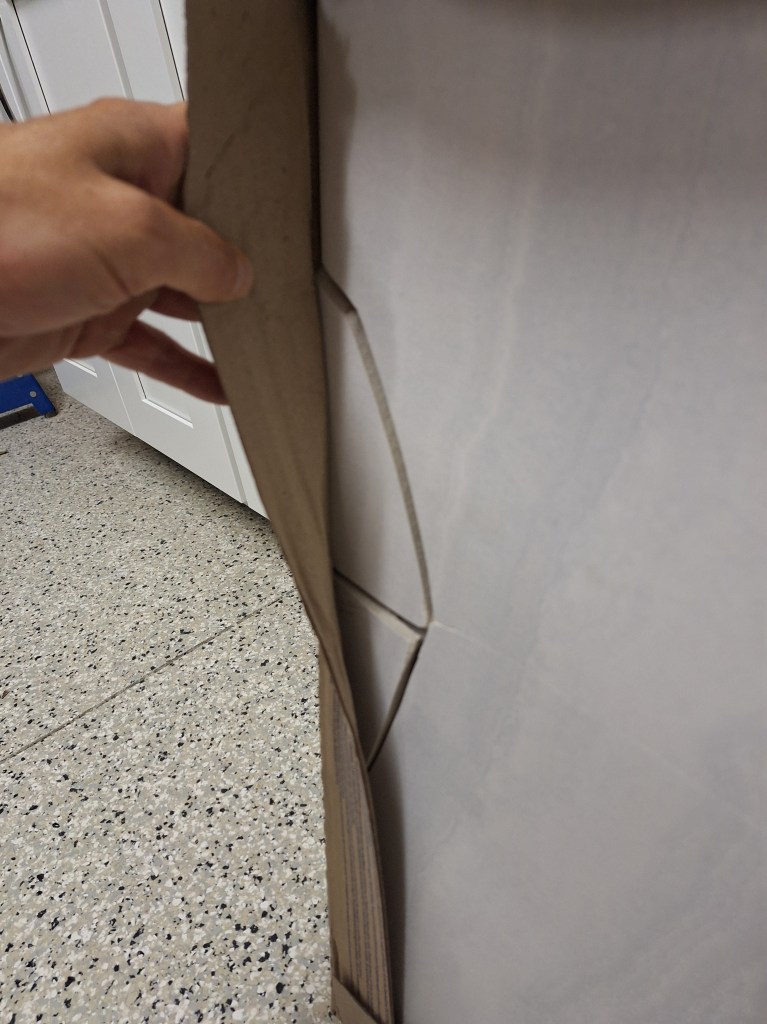

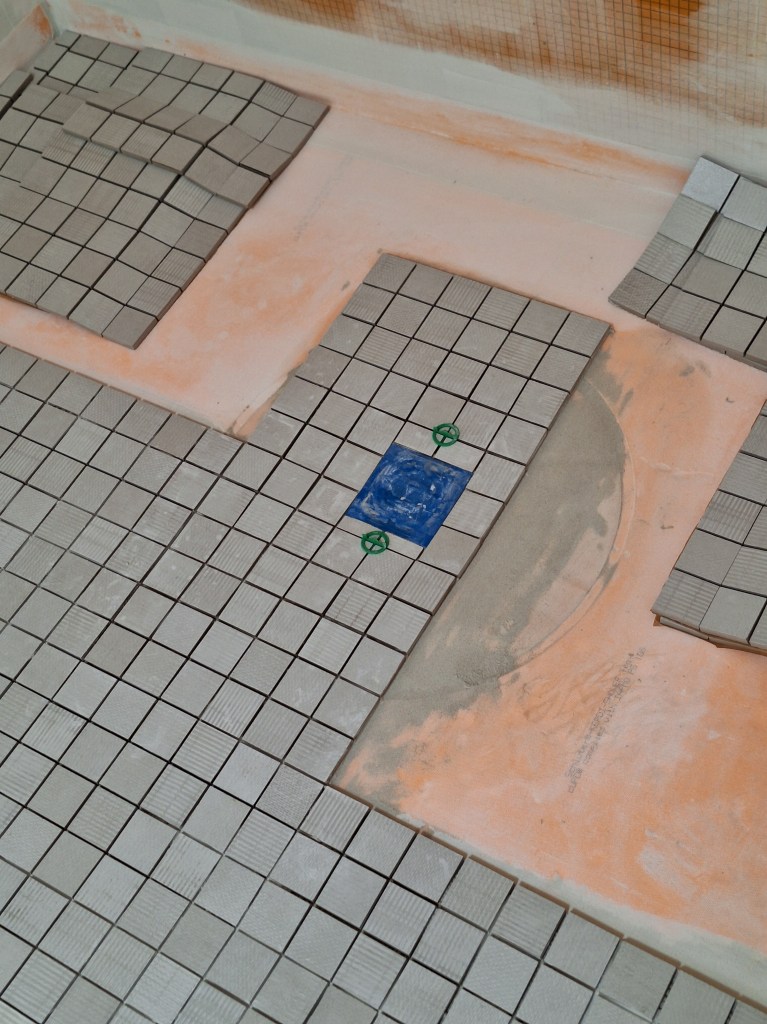

In my last post about the master bathroom, I had picked up the baseboards and glued together the two pieces that would form the whole. They were now ready to be installed. I did this along the long walls first, then went into the toilet alcove, where I had a bit of an issue that was a consequence of a poor job of tiling that area. Recall that I had to wait on new tiles to finish that area. When I got back to it, I focused my attention on making sure they aligned well enough with the existing tiles. I didn’t think about whether they were sloped or not. Unfortunately, there was a slope, and one that was too large to ignore. Even though the gaps were behind where the toilet would be, and therefore not especially obvious, I still wanted to see what I could do with them to make it less obvious. So I cut out and fashioned a couple of custom strips of wood and glued them in place to fill the gaps. Although I don’t have a “before” picture, you can see from the strip I put in, that it was not trivial.

Once the glue dries and they area caulked and painted, they will look much better and be virtually invisible.

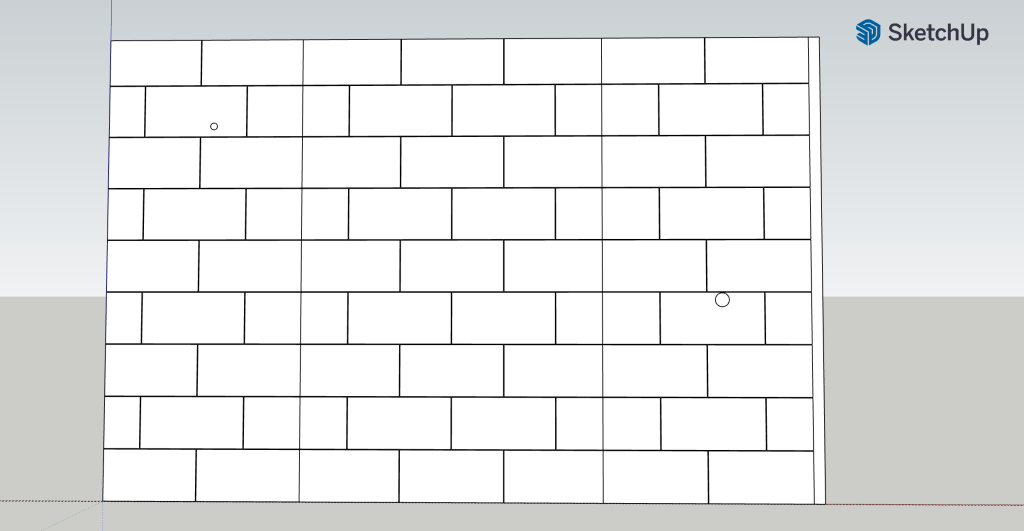

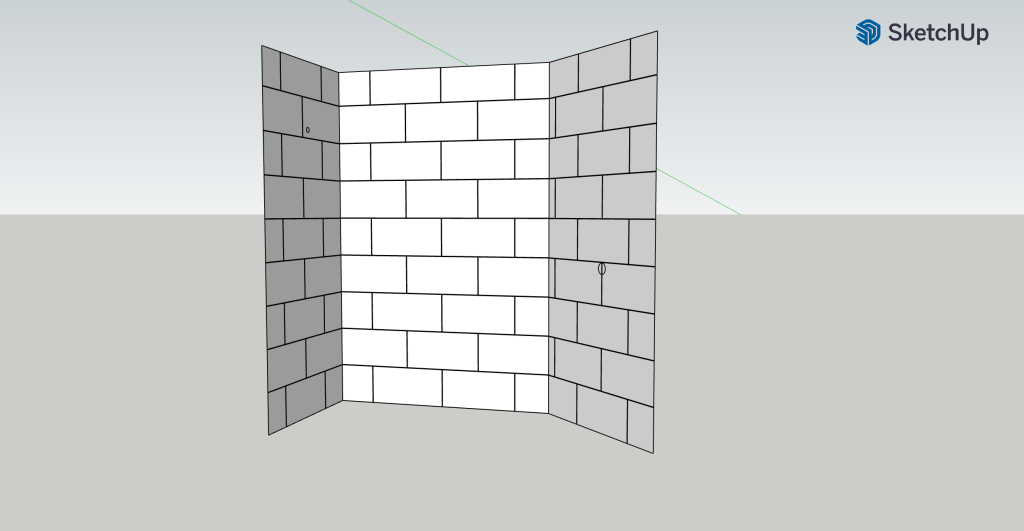

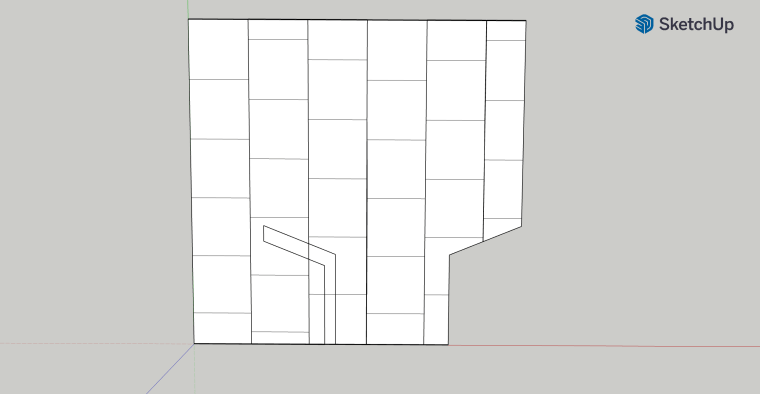

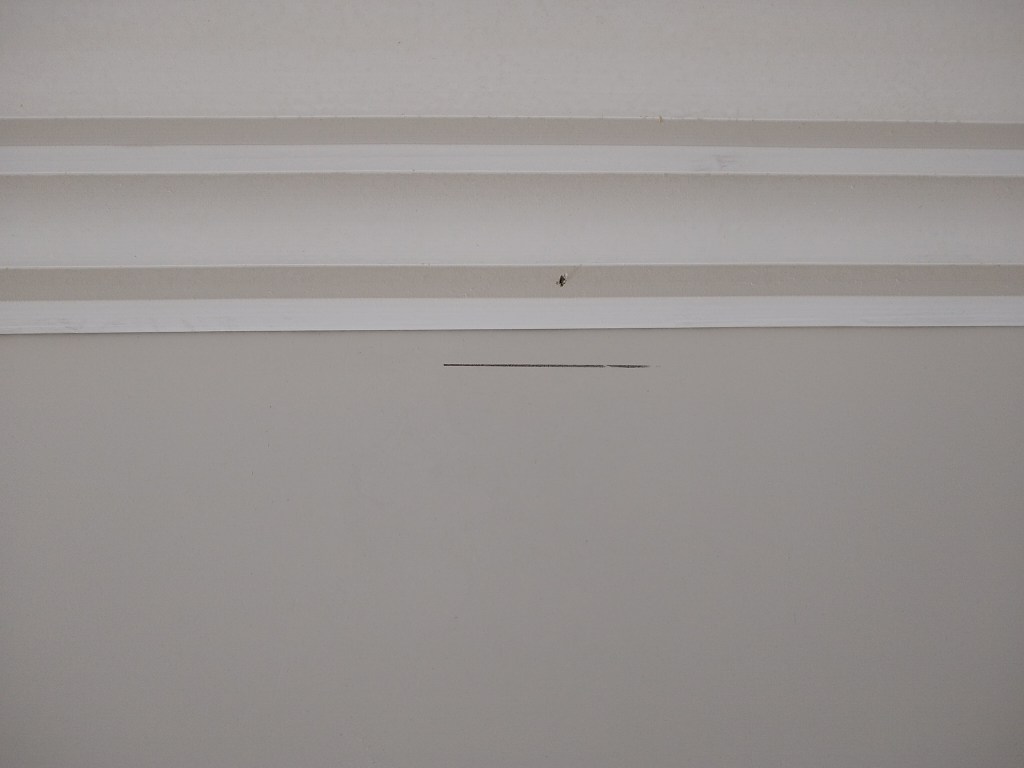

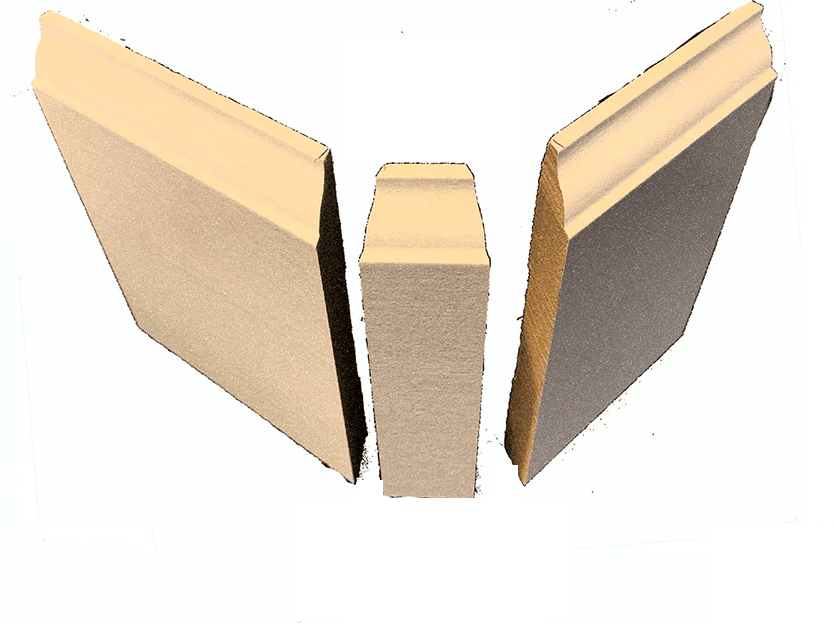

As you come out of the alcove, the wall makes a turn that produces a rather sharp outside corner. The angle here is 68 degrees. Cutting the baseboard in the usual way would make this a very pointy outside corner, and one that would be susceptible to damage. So I explored creating a three piece outside corner, kind of like what you see below.

However, after many attempts and modeling in SketchUp, I could not get this to work. I believe this is because I have such a complicated profile, a more acute angle, and a sharp (not bull-nose) corner. The situation shown above is intended to deal with a bull-nose corner. It’s pretty simple because the angle is 90 degrees and most of the baseboard is flat. At least that is my sense of it. Perhaps one day I’ll figure it out. Unfortunately, I could not find anything online to show how to deal with such a situation, which made me feel like it wasn’t doable. So I needed an alternative. I decided to create an outside corner block. Kind of like this.

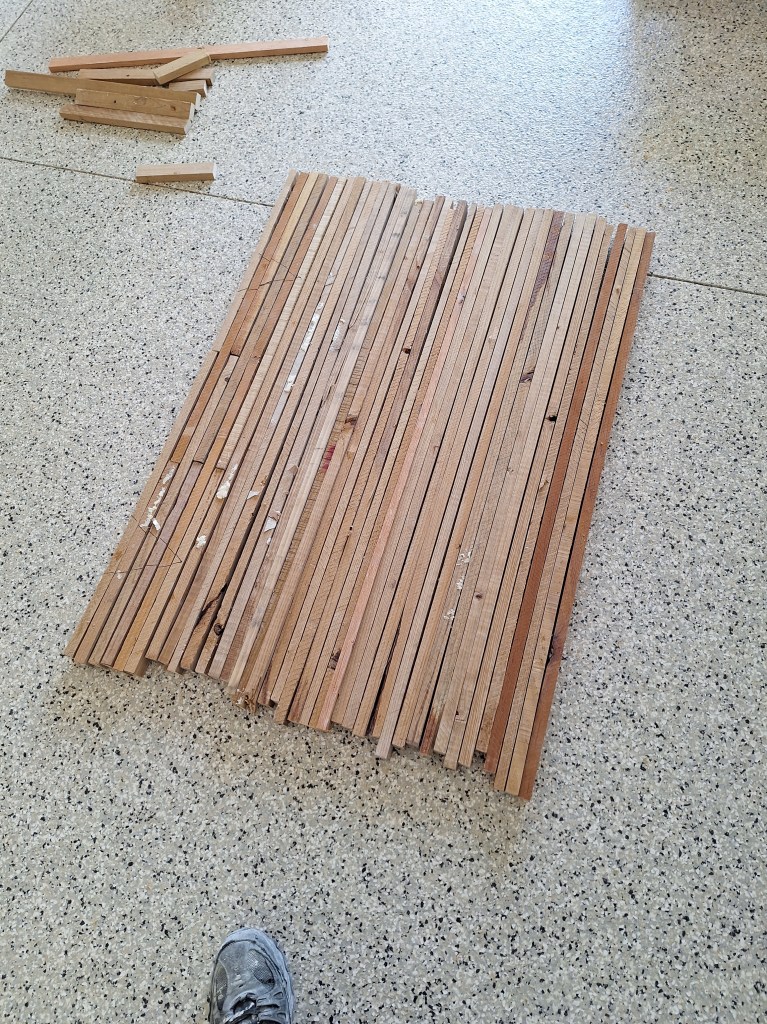

So I started building one. Here are the three pieces before gluing them together.

The two outside parts of the block are built up from two thinner pieces of stock in order to give them some heft. The middle piece ties them together as you can see below after I glued the three pieces together.

With this arrangement, I can simply butt the baseboard to the ends of this corner block. The corner block presents a flat face as you round the corner, making it more resilient to knocks. To dress it up a little, I added a decorative top using basecap. Here it is in the raw.

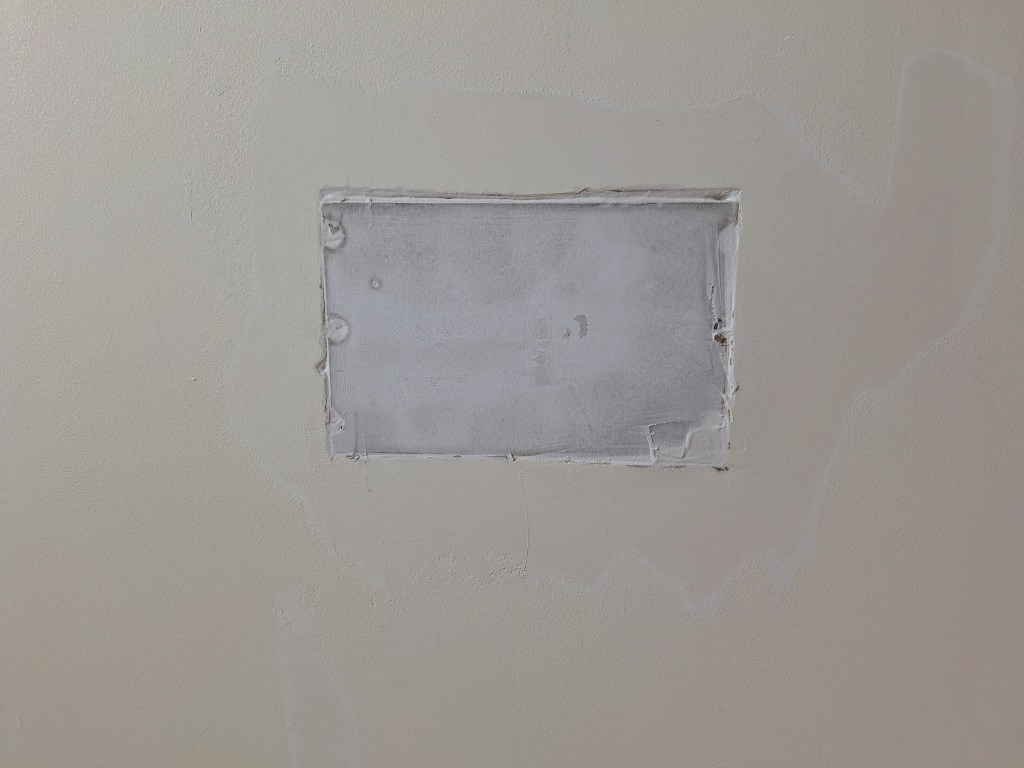

The block part is painted, but the basecap is not. In this image, I had just glued it together and placed it on top of the block. I then put it in position without fastening it to see how it looked.

The short piece of baseboard that butts up to it in the image above is not fastened either. I just placed it there to see how it looked.

The basecap is not as flush with the wall as I’d like, but it was very tricky to get those angles perfect. To get it to fit just right, I’d have to modify the angle of each of the four pieces by a small fraction of a degree. You can’t just modify one of them because the profiles won’t line up. I decided not to risk it and will let the caulking fill those gaps. It’ll look just fine.

After a bit of sanding and painting, the corner block was done and I could finally finish the baseboard installation. Here are several shots from different angles.

One could question the value in putting baseboard along the entire length of the vanity wall, since most of it will be covered up by the vanity. My vanity has legs, so if you get down low enough you can see it. So I decided just to do it.

Where the baseboard meets the tiled shower walls, I added a return to terminate it nicely. Here’s a closeup of one of them.

In the above image you can see the outside corner block and how the baseboard ties into it. Here are some closeups.

I think it looks pretty good and will stand up much better to knocks than if I’d mitered the two pieces at that corner. And here’s a look inside the toilet alcove.

In the image above you can also see the toilet flange I had just installed in preparation for the toilet, which I did next. Here it is.

And here’s one with the seat up. Sorry, just clean water in there.

This was my very first toilet installation. It was all new to me, and I got kind of lucky with it. The toilet only just fit. The center of the toilet flange is supposed to be 12″ from the finished wall. Mine was 11 1/2″, which was a mistake due to not taking the thickness of the drywall into account. Online, some people claimed they prefer to use 11 1/2″ to get a tighter fit, which gave me some relief back when I first realized my mistake. I was hopeful I would get away with it. In the end, I did, but 11 1/2″ was not appropriate here. I had no wiggle room at all. The back of the toilet is right against the wall, and with my rather beefy baseboards, there is only about 1/8″ of clearance between the baseboard and the base of the toilet. Another stroke of luck was that the tank lid is the same size around as the tank. In my experience, is not that common. I’m used to it being larger, like a lid of a jar. Consequently the lid fits on the tank as intended.

With the baseboard done and the toilet installed, I could now move the vanity into place. Upon doing so, I discovered that I could not push the vanity right up to the wall. The back legs were directly inline with the back of the cabinet rather than inset. Consequently, the thickness of the baseboard prevented it from lying flat against the wall. There was about an inch gap.

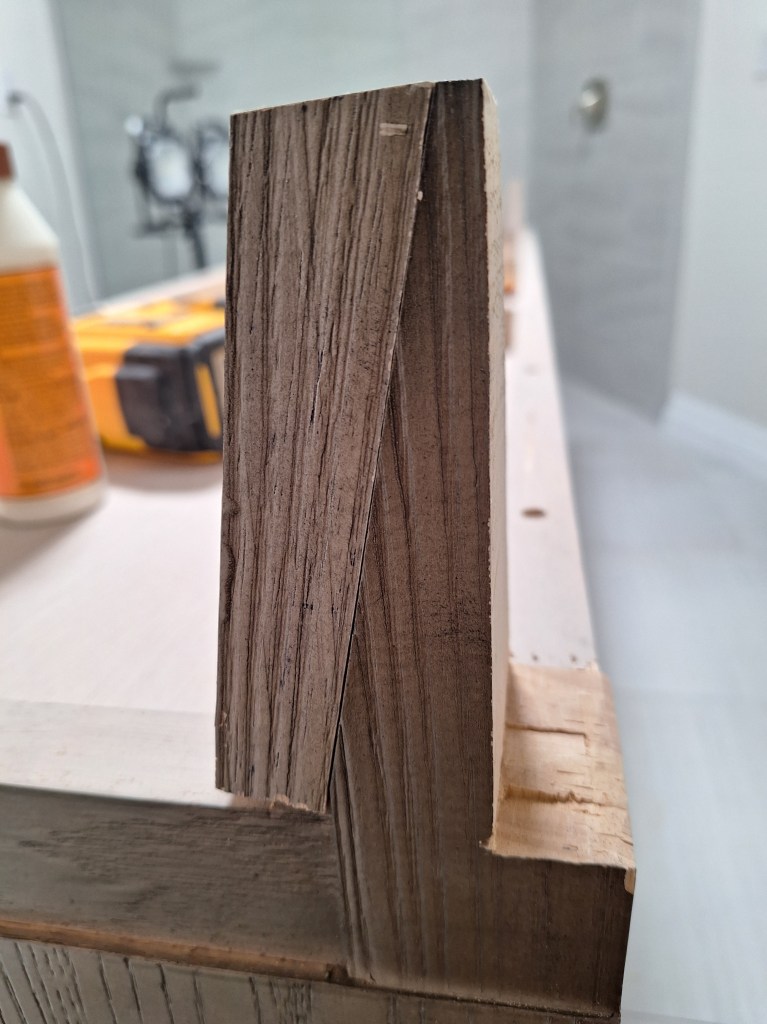

I turned the vanity upside down on the floor to explore my options. I was hoping the legs would come off and that I could reposition them, but wasn’t optimistic about that. Since the vanity is quite heavy and would require very sturdy legs, simple screw-in legs were unlikely, which was what I discovered. I also considered cutting the baseboard just enough to let the feet slide in, but I wasn’t keen on that. The baseboard should not need to accommodate the vanity. One day I may decide I want to change it out for another one. In the end I decided to modify the back legs of the vanity to accommodate the baseboard. So I marked out what I wanted to cut, and got started.

In the image above you can see how I traced out the baseboard profile in order to minimize what needed to be cut (keep in mind it is upside down). I wanted to preserve as much of the foot as possible, which wasn’t very much. I started my cut with a back saw, but had to complete it with a panel saw because the plate of the back saw could not take it all the way. The image below is of the other leg.

Once the cut was complete and cleaned up a bit with a chisel, it looked like this.

Here is a shot with a piece of baseboard held up to it so you can see how it fits.

There will be a screw-in pad under the leg, so there is plenty of room for the baseboard.

Although the back legs look like stiletto heals, they are quite strong. They are made of solid wood, so once the vanity is in place, it would be well supported with just that amount of wood. However, I would be less confident if it was moved around a lot. So I decided to use the off-cuts to bolster them. Each leg received the off-cut of the other in order to keep the finished side out. Although you have to go out of your way to see these legs, this makes them less conspicuous should you try.

These were attached with glue and brad nails, which was plenty. However, I decided to add a wedge to fill the gap, just to be extra careful.

Although the support wedge is a different color, it is set in a bit, so from above it is not visible.

I then plugged the hole at the bottom that would receive the plastic pad. I couldn’t simply reuse the existing hole because it was angled. So I glued a dowel in and let it sit overnight before drilling a new hole that would go straight down.

The new hole was then drilled and the threaded insert put into the hole, followed by the plastic pad.

After both pads were added to the modified legs, I was able to move the vanity cabinet into its final location.

The blue tape on the wall marks the center between the where the vanity lights will go. It is now sitting flush with the wall, as you can see below. The vanity will not be fastened to the wall. It will simply sit against the wall like a dresser in the bedroom. It’s very heavy, especially with the marble top, so I am not concerned about it shifting if it is knocked.

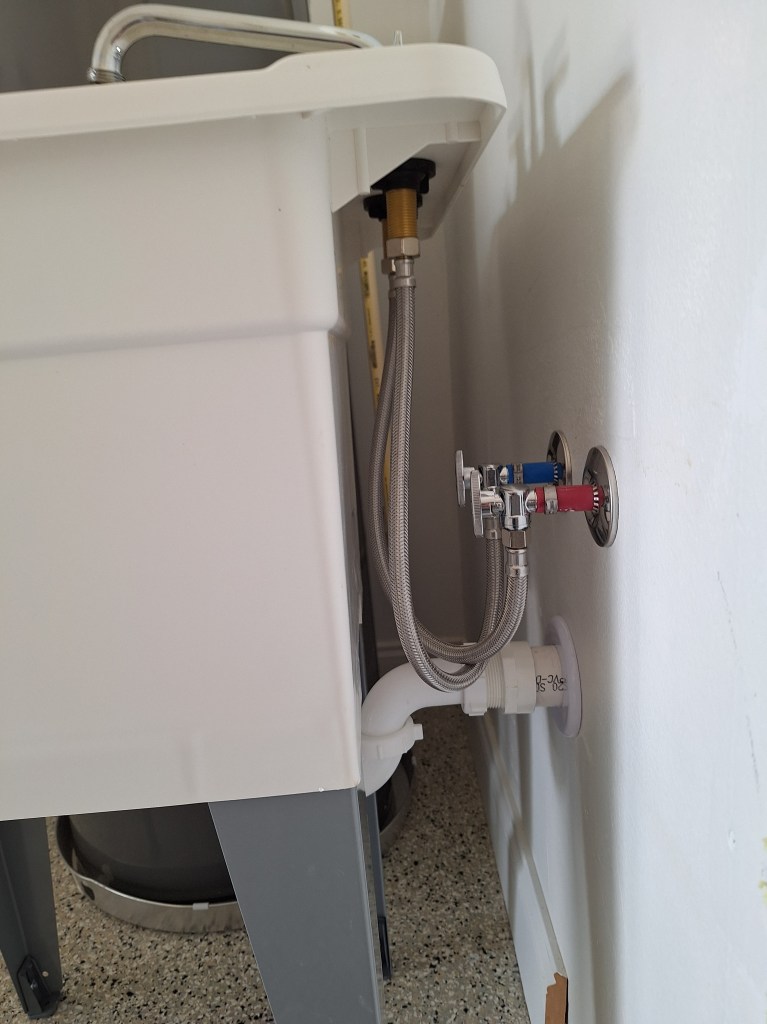

I also added the angle stops for the sink supply lines.

I had to widen the opening in the shelf below the right sink to make room for the the drain.

The next task with respect to the vanity, was to put the marble top in place. It is a massive thing and something I could not do on my own. With the help of a couple of neighbors, we managed to put it in place.

The backsplash came in two pieces that simply butt together. Unfortunately, one of them was not quite square, so when I pushed them together, there was a gap. I used my angle grinder to straighten it, after which they came together nicely. I used silicone to secure it to the marble top, then applied a bead of silicone at the seem between the top of the backsplash and the wall. That should hold it. I didn’t want to apply silicone to the back of the backsplash to adhere it to the wall because I wanted to minimize any damage to the wall should I choose to change out the vanity some day. If I ever did need to remove the backsplash, the bead of silicone between it and the wall would only require minimal repair to the drywall, if any.

The faucets were added next.

After that, the drain and supply lines needed to be hooked up.

With that done, I now have a functioning bathroom. The vanity lights and mirrors still need to be added, along with other bits and pieces (like towel rods, etc.). At the moment I’m not sure whether I want to have a single large mirror or two smaller ones. Decisions like this can be made much later, even when I’m living in the house, so I will put them off so that I can start work on the guest bathroom.

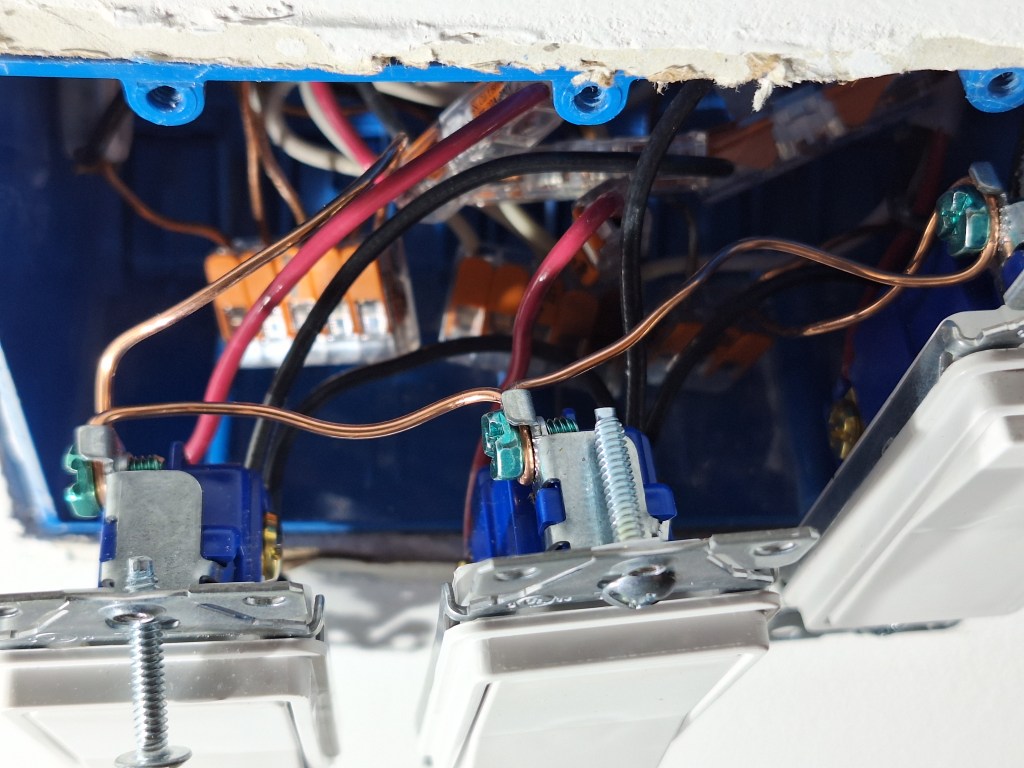

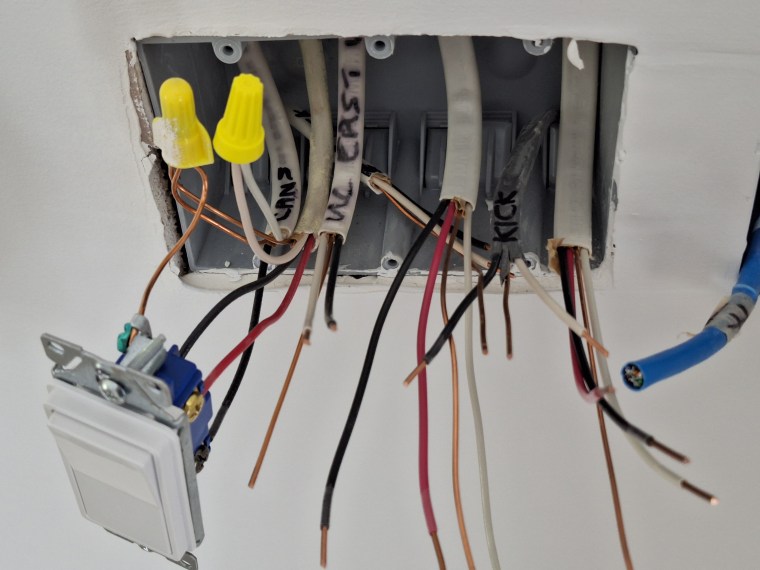

One more thing before we go. In the June/July post I talked about installing the hot water heater. At that time I had not yet had my work inspected. During this month I had the inspection done, but failed. I needed to add a pressure relief valve between the main supply line and the hot water heater. I was under the impression the relief valve that came with the tank was sufficient, but the inspector informed me that it was for relieving pressure when the temperature was too great. The valve I needed was to relieve pressure when the water pressure from the city fluctuates. That is, at different times of day it can change. An adjustable pressure relief valve is needed to keep the pressure consistent. So I have since installed it, as shown below.

As you can see, I tee-ed off the main cold water line (purple primer everywhere). The PRV has a dial at the top of it (left in the image above since the valve is installed on its side) that is used to adjust the pressure to what you want. If the pressure exceeds that, the excess will flow out the line going down and out of the garage.

This was just inspected, and I passed. So on to the guest bathroom.