I took an unplanned hiatus through most of May, initially due to a cold. Once recovered from that, I was further delayed by my own hesitation about pulling the trigger on the drywall. I wanted to make sure that was the next step before I made the purchase. After convincing myself that it was, I took the measurements to establish how many sheets I would need, excluding the master bathroom (not sure what I’ll do there yet), My objective was to use as large a sheet as I could where possible to reduce the seems that would subsequently require taping. My measurements revealed that I would need 35 sheets of 12’x4′ and 60 sheets of 8’x4′.

I first visited Lowe’s intent on making a purchase and arranging delivery. Unfortunately, Lowe’s would only deliver the drywall to my garage. I wanted it placed inside the house. I would be hanging it by myself, so moving it from the garage into the work space would be a major chore by myself. So I went to Home Depot next and, fortunately, for an extra charge they would carry it into the house. I didn’t make the purchase that day. Instead I went home and looked online for other options before I committed to it. I didn’t find anything, so I called Home Depot and made the arrangements over the phone. We set a date and a time window .

I drove up to meet the delivery crew on Wednesday, May 19th at the designated time. When the driver arrived he was by himself, which surprised me because moving all the drywall into the house would be a big job for one person. I mentioned this when he approached me only to learn that he was not planning to carry it into the house; only put it in the garage. So, he got on the phone with the store for about half an hour with little result. In the end he left without unloading the drywall. So I drove to the store to discuss it with them. They made arrangements for another attempt on the Monday, May 24th, this time with additional labor. I drove up again on the Friday and waited. I stopped in at the store to make sure all was in order and was told it was. Nearing the end of the delivery window I got a call informing me that they’d have to do something else because the usual delivery service did not carry into the house. So we set it up for the following Friday. The third attempt was successful. My drywall was placed where I asked.

Note that the above pictures were taken after I had already finished hanging the drywall in the guest bedroom, so if you looked really closely, you’ll see that there are less than 35 sheets of the 12′.

The next day I hung my first ever sheet of drywall! I had several reservations about doing this myself, especially with the 12′ sheets. My biggest concern was how I was going to mount a 12′ sheet on the upper section of the wall up to the ceiling. I did some research on YouTube and learned that I could do it using the lift I had. Until viewing that video, I’d only used the lift for raising things up to the ceiling and was unaware that it had features to assist with hanging drywall on high walls. That was my first and biggest problem solved. I would not have to rely on another person. A big relief.

Another concern I had was how I would maneuver the sheets from one room to another. I was pretty sure I could use a couple of dollies I had, and that turned out to be the case. At first I used both dollies. It worked, but was little tricky steering. I then discovered that using one was sufficient and much more maneuverable. So another problem solved. Below I show a big 12′ sheet on the single dolly.

Now that I’ve shown how I move the sheets by myself, let me show the process of hanging a 12′ sheet. Using the dolly, I move the sheet into the room I am working on and get it close to the lift. I then have to physically pick up the sheet and place it onto the lift. That is not easy, but after trying several techniques I figured out how to do it without too much effort.

The pics above are of the sheet on the lift positioned to go on the north wall of what will be the office. I had already finished hanging the guest bedroom and the west wall in the office before I started writing this post. It was only when I started describing the process that I realized that pictures were required. So what you’re seeing is not my first attempt. The pics show the lift moved close to the wall. This is the first step. Next I must tip the top of the sheet so that it rests against the wall. In the image below, you can see that the bottom edge of the sheet is still supported by the lift, but the top edge is not. It is now leaning against the wall. For this to work without the lift rolling away, it has a set of brakes with rubber ends to prevent the lift from moving.

Here is a closeup of the brakes deployed.

Now I just raise the sheet into position. It simply rides up against the wall as I turn the handle.

Actually, with a tight fit like this one, it takes a bit of maneuvering. I turn the crank, adjust the sheet, turn the crank, etc. But it is pretty straight forward. Once in position I pull out the ladder and drill a few screws into place at the top. Three screws are enough. Then I can roll the lift away and it will hang by itself.

After that it is just a matter of adding enough screws to firmly fix it in place. Before I place the bottom sheet which, of course, does not require the lift, I cut out the window opening. But I will discuss those details later. Now that I have explained the process of hanging sheets, I will describe what I experienced as I began the process.

Being new to this, I decided it would be a good idea to gain experience (i.e., make beginner mistakes) in a room that would be the least used. So I started in the guest bedroom. I figured out how to move and lift the sheets by myself, as described above, but there were still several other firsts I had to face.

The first sheet I hung was a full 12’x4′ sheet, requiring no cuts. Here it is below.

The next sheet, however, would require cutting to fill the relatively small area adjacent to my first sheet. Cutting a sheet seemed pretty simple, so I just followed the directions I found online. Sure enough, it was simply a matter of cutting a line through the paper with a utility knife, then snapping it. The sheet broke easily on the scored line. I then used the same knife to reach under and cut the paper on the other side. Voila, another mystery solved. It also required one more step; using a rasp to smooth the freshly cut edge, but that was very simple using the following tool.

This tool has two uses. It can be used to raise the bottom of a sheet of drywall using your foot and a lever action to meet the sheet already in place above it. The idea is to create a tight butt joint. The other use comes from the part in the middle of the tool that is a rasp you can run along the edge of a freshly cut sheet to smooth it out. It works really well.

So I fastened that piece to the end of my first sheet to finish the top of my first wall. The bottom part was a bit more involved, since it required some cuts for outlets, as shown below.

To cut the openings for the outlets, I started using the manual approach whereby you simply measure the distances and then cut with a drywall saw.

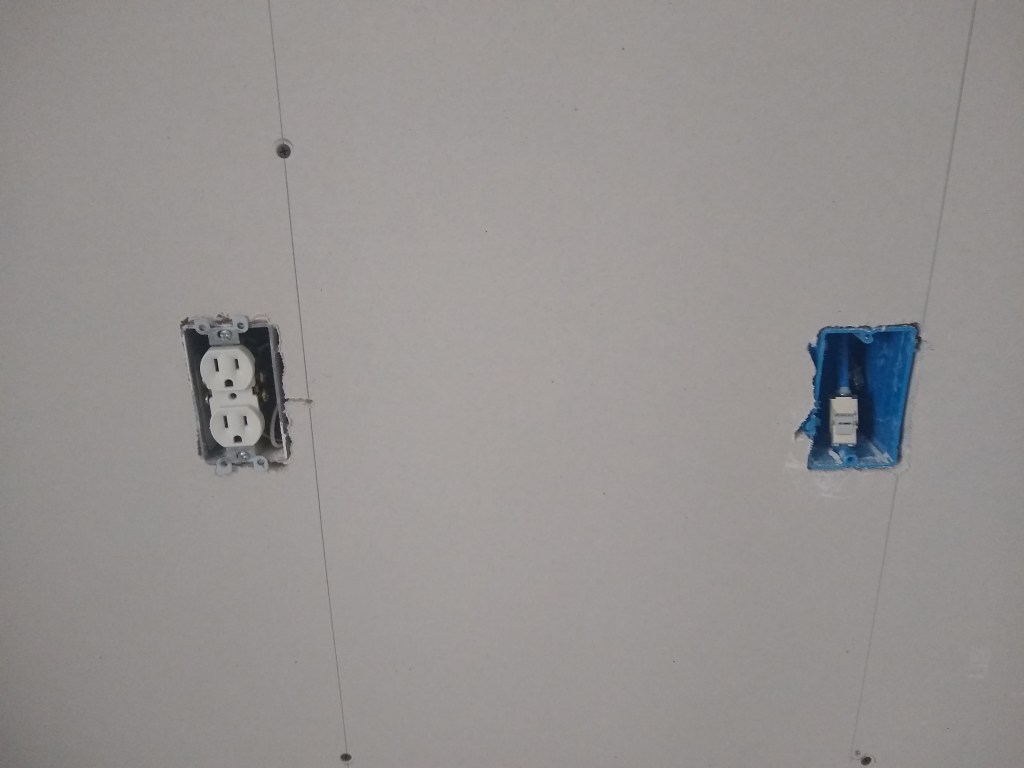

This worked fairly well, but it was very time consuming. It also had the disadvantage of not always lining up how you expect. You measure as best you can, but when you actually fit the sheet, there will inevitably be some variance. Here is what it looks like close up.

These are not bad and will be easily covered by the face places, so no patching will be required. However, the measuring and cutting before putting the sheet up really interrupts ones momentum, so I decided to try my hand at using a cutting tool with a RotoZip bit. Here is what I bought.

Notice that the RotoZip Bit has a smooth tip. This is the part the will guide the bit along a surface without cutting it, as I describe in a moment.

My research revealed that a cutting tool and RotoZip bit seemed to be the preferred method used by professionals. The concern for me was that it was going to take some practice to learn how to use it without making a mess. The way it works, is that you first remove the outlet and push the wired to the back of the box. You make a note of where the center of the box is then place the sheet over the outlet and fasten it loosely using screws that are not really close to the outlet itself. You measure to where you noted the center of the box to be and plunge in with the cutting bit. You then move the bit (i.e., cut) over to the edge of the box. You’ll feel the bit stop when it touches the inside edge of the box. Then you pull the bit out a little and move the bit over to the outside edge of the box and trace around it, cutting away the drywall. This is the tricky part for the inexperienced. You have to get a feel for it, which takes a bit of time. Here are my first three attempts.

As you can see, these are pretty ugly, especially the third one, and will require patching. For a professional, patching mistakes like this is a real nuisance, costing time/money. However, for me, I am not time constrained, so I will “embrace the suck” and view this as part of the process. I did get better and expect I will continue to. Here are my fourth and fifth attempts. They are not perfect, but are acceptable and will require no patching.

I also use the cutting tool for other openings, like doors and windows. Here is the second wall I started in the guest bedroom. The 12′ sheet covered the doorway, so I used the cutting tool to open it up after the sheet was in place. It works nicely for this and is a much simpler process as one simply follows the door frame (no need to pull out and plunge in). As a side note, the hole in the ceiling was done a long time ago as we explored the framing. It will be patched in due course.

Here are a few shots of the guest room after I finished hanging the drywall.

During the process of hanging the drywall in the guest bedroom, I found that setting the screws was a bit erratic with the impact driver, even using drywall screw setter bits to limit the likelihood that I would drive the screws too deeply into the drywall. You’re supposed to sink them below the surface without breaking the paper. So I decided to purchase a drywall screw gun; a tool specifically designed for this.

With this tool, when you pull the trigger, the motor spins, but the bit does not turn until you press the screw into the drywall. It is the pressure that causes the clutch to engage, and then it drives it in quickly. You can adjust the depth to sink the screw head to your desire depth. I found this was a very worthwhile purchase and made the process much more consistent. I’m very happy with it.

In addition to screws, I am also using construction adhesive to glue the sheets to the studs, where possible. Although many were split on the need for it, it appeared that most felt it was worth while and that it would reduce the likelihood of screw pops in future. The idea is that as the framing naturally moves (slightly) over time, the extra adhesion will prevent the drywall from pushing and pulling against the screws. The extra cost for the adhesive is not much and it takes very little time to apply, so I figured I’d do it. Unfortunately, it can only be done on interior walls, since the furring strips you screw to on the exterior walls are covered with an insulating material, so I’m not getting 100% coverage.

Some other lessons I learned while hanging the drywall in the guest bedroom was that it is a good idea to look for opportunities to do some prep work. Many walls are not straight and will require shimming. Also, in some places, especially in the corners, there is not always a lot of wood available to screw the sheet to, so it can be beneficial to add nailers.

As of the time of this posting, I have hung two bedrooms (guest bedroom and office) and am half way through the third bedroom (workshop). I have ordered 100 feet of mass loaded vinyl to use as sound insulation between the workshop and office, which will arrive this weekend. I will put it up and see how it works before purchasing more for the other interior walls to which I intend to add sound insulation. Where it makes sense, I want to reduce the sound that can travel between rooms (i.e., bathrooms and bedrooms). But I’ll talk about that in another post. Once the drywall in the workshop is hung, I think I will return to the guest bedroom and try my hand at mudding and taping so I can get some experience with that before continuing with the hanging. It is likely that the lessons learned from that experience will impact how I hang the remaining drywall. Since there is so much more drywall to hang, now’s the time to discover them. So stay tuned.