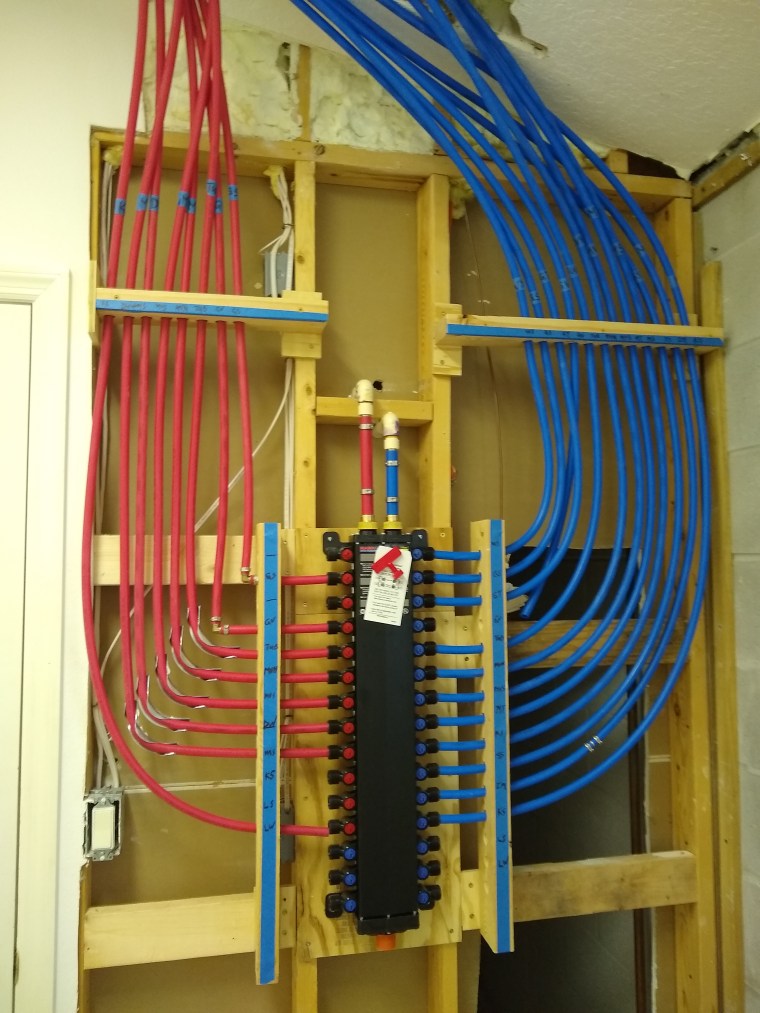

The Manabloc arrived in early January, so I mounted it.

To support the lines connecting to the sides, I fashioned a support similar to the ones I made for the PEX lines in the attic. The distribution linea must be properly supported to make sure there is little stress on the connections.

This seemed to work well, so I expanded upon it.

The mess of lines is now starting to look more ordered. I used blue painters tape I had handy to identify each line so there would be no confusion as to what line supplies what fixture. Note that I have not yet connected the lines to the Manabloc because I need to move them out of the way in order get access to the existing copper.

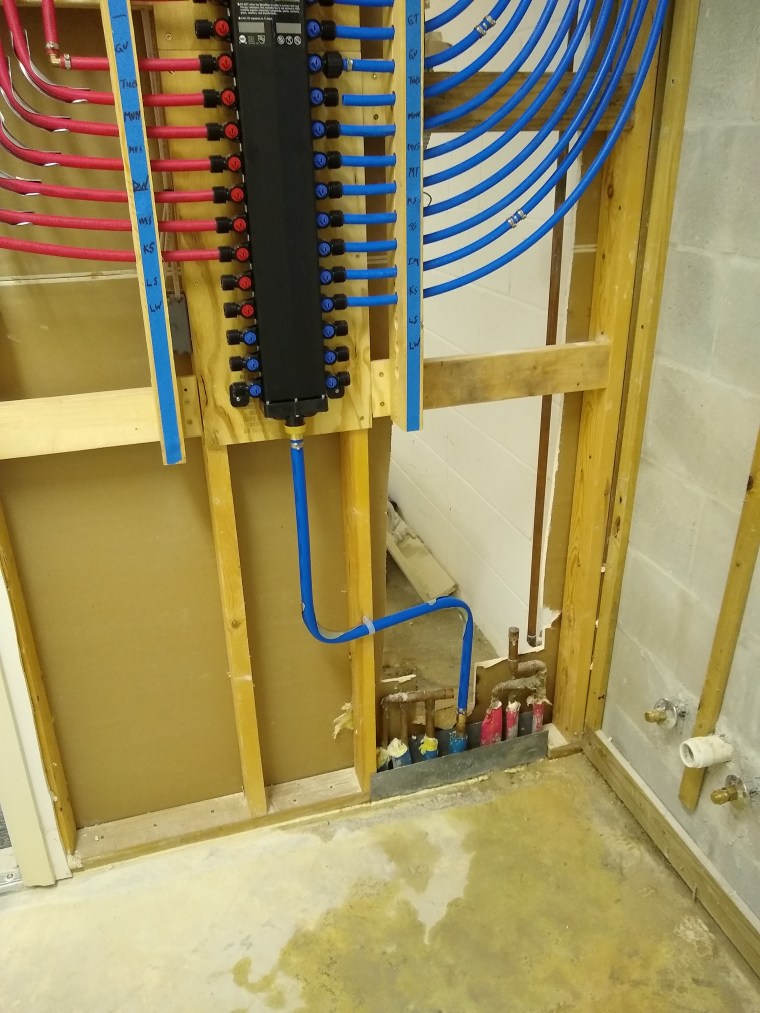

With that done, it was time to figure out how I was going to connect the hot water heater and main supply line. To get proper access to the copper feeding the hot water heater, I removed the drywall on the garage side and disconnected the hot water heater.

I also cut out the copper pipes to the hot water heater and capped them. This can be seen in greater detail below.

PEX is not supposed to be directly connected to the hot water heater. You are supposed to have about 18 inches between the lines coming out of the water heater and the PEX. So I decided to use Chlorinated Polyvinyl Chloride (CPVC) to connect to the hot water heater and have the PEX interface with it to connect to the Manabloc (shown in first image below). CPVC is much easier to work with than copper. The connections are simply glued, so no soldering required. For now, I created a simple loop-back for the hot water pipes, as shown in the second image below. I don’t have any real need for hot water at this point, so I intend to hook up the hot water heater only after the garage floor has been finished (probably an epoxy finish). With it disconnected, I can move it out of the way when I finish the garage floor.

You should also have noticed that in the image above that the PEX lines have now been routed through the support and into the Manabloc. Only three are actually connected: one blue for the guest toilet and a red and blue for the guest sink. Even though there is no hot water yet, I still want the water to flow through the red line to the sink. Although connected from the Manabloc to the fixtures, there is still no connection to the main supply. Notice that the bottom connection of the Manabloc is not yet hooked up. That is the last step. All has to be in place before I make that move, otherwise I am without water. Remember, the copper pipes are still feeding the fixtures in the guest bath for now.

So the next step is the actual cut over. Once I sever the supply line from the rest of the copper, I am committed. This operation would need to be completed in short order. Until it is completed I’d have to find somewhere else to pee (or worse!). So I was a bit nervous about this, especially because I intended to solder the PEX connection to the main supply line and didn’t have a lot of experience with that.

For the next part, I don’t have any pics, I’m afraid. I was a focused on the task at hand. I first hooked up the toilet and faucet in the guest bath to the PEX lines. That was simple enough. Then came the soldering job. So I got out the torch and made sure the copper was cleaned and fluxed. I lit up the torch and did my best to get the solder to draw into the joint. It was hard to tell if I was successful. There was a lot of solder all over the place, but I wasn’t sure if it was where it needed to be. I connected the PEX to the supply line and Manabloc and turned on the main. Unfortunately, that didn’t work. Lots of leakage from the “soldered” joint. At that point I needed some assistance, so I shut off the main and headed home.

I called a plumber I found on Angie’s List. His name was Joe (yes, Joe the plumber). The next day while I was at the house he called and I explained the situation. He asked me to send a couple of pics via text and then called me back with a solution. He recommended a SharkBite connector, which he uses all the time and doesn’t need any soldering. You just press it onto both the copper and the PEX. Easy peasy. I immediately went to Lowes, picked up the part and installed it. What a great guy. He didn’t even charge me. It worked like a charm. I was cut over.

Had I known about the SharkBite connector I could have saved myself a lot of worry. Live and learn. It was very exciting to see the water flowing from the PEX. It was working just great. No leaks. I later discovered after removing and inspecting the attempted solder connection that there was no solder in the joint. The joint must not have been heated up sufficiently to draw the solder.

On the next trip I climbed into the attic to make sure there were no leaks, which of course, there weren’t. If a leak was to exist, it would’ve been at a connection point, and there are no connections over the lines in the attic. The only connections are at the Manabloc and the fixtures, so my inspection was just a formality. There would have to be a defect in the PEX itself for there to be a leak above the ceiling. Nevertheless, I will continue to inspect the lines in the attic for each new fixture I bring online.

As a final step for this part of the project, I cut back the copper that used to extend from the walls into the cabinets and capped them. By “capped”, I just mean that I placed a copper cap on the end and taped it so that it would keep any critters out and be obvious to anyone that the cap was not soldered on. No water will be flowing through the copper anymore, so I did not need to take extra steps to secure the caps.

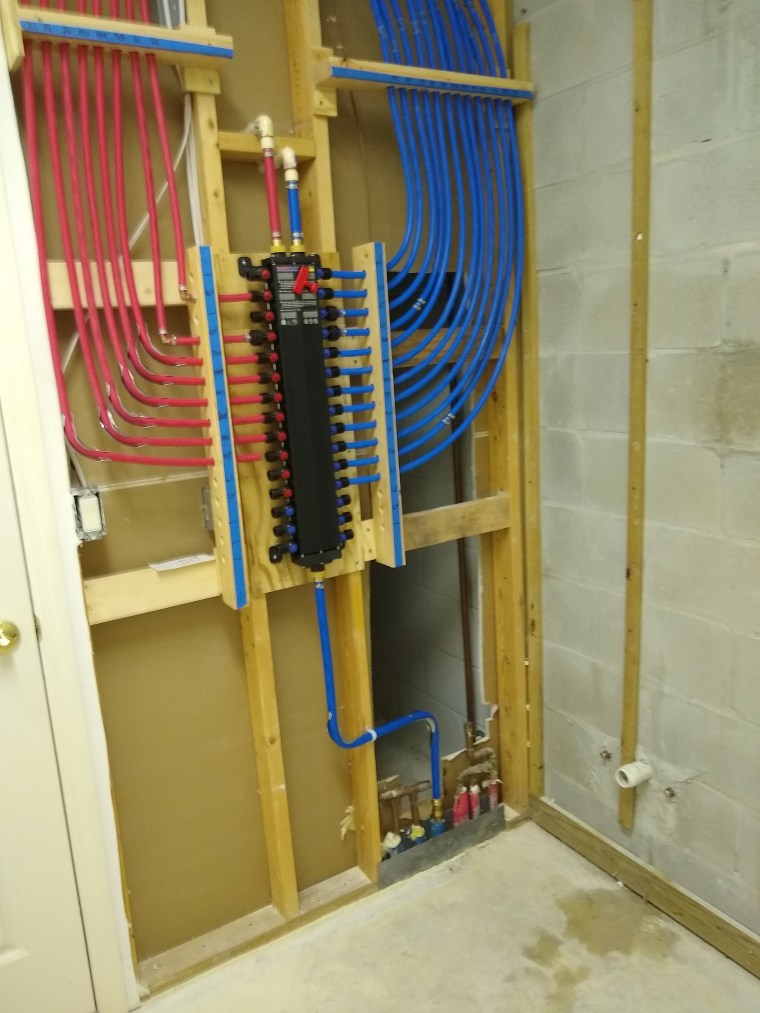

Here is where the new plumbing setup currently stands.

Somewhere down the road, I will enclosed all this. I expect it will be a shallow closet that will provide me with full access to the all the lines. This will probably mean I’ll need sliding doors so I can have easy access to all of it and not have the doors take away anymore space, as bi-fold doors would. But that is something I will explore much later.

With this system in place, it will be very easy to hook up the fixtures as I move forward. PEX is very friendly. Although I can’t really say the plumbing is complete, I feel as though it is because all that remains is well understood. So now it is on to the next job: running Ethernet cable throughout the house. Oh no! More climbing around in the attic.