Final Inspection – July 2025

The countertop installers arrived on the first of the month. The started by placing the slabs on the base cabinets. The granite countertop, where the cooktop will be, was delivered with the opening for the cooktop not fully cutout in order to retain its integrity during transport. This can be seen if you look closely at the area the guys are facing in the image below, where they were preparing to cut that bit out to open up the space for the cooktop.

Here it is ready for the cooktop.

As for the island, there was a bit of a problem. At either end there is a hole for a 3″ popup outlet, (you can clearly see one of the holes in the first image above). While cutting one of the holes, they slipped, leaving a mark just outside the hole. They were hoping that, once installed, the part of the popup outlet that sits on the countertop would cover it up, but it did not. So this could have been a big deal, meaning the slab would have to be replaced. Before doing that, we decided to order a larger popup outlet (4″), expand the hole, and see if would cover the blemish. I was very skeptical that it would work because below the countertop there was very little room to expand the hole. That is, the hole was very close to the back of one of the cabinets, so I didn’t think there would be enough room to accommodate the collar that screws onto the outlet from below the countertop to secure it. Since the alternative was to scrap the blemished slab, there was no harm in trying. So we ordered a single larger popup outlet and waited for it to arrive.

In the meantime, I returned my attention to the ducting that would vent the cooktop exhaust out of the house. In my last post, I had installed the small cabinet above the cooktop and originally planned to use flex pipe to connect it up, as shown below.

Unfortunately, this wasn’t going to work as you can see from the image. Not only that, but you’re not supposed to use flex pipe in this situation because the ridges in the flex pipe increase resistance to airflow, providing a better opportunity for grease to accumulate. I learned this by accident during a conversation with the guy who installed the wall oven. Given this, I sought to have custom ducting created to replace most of the flex pipe, as mentioned in my last post. I would not be able to replace all of the flex pipe. The portion that is above the cabinet and extends to the roof is no longer accessible, so it would have to remain and the new ducting would have to connect to it at the top of the cabinet. That, I believe, should be fine because the primary area of air flow resistance will be in the bend within the cabinet. Once the air exits the ducting within the cabinet, it is a straight run to the roof and out of the house. Fortunately, the custom vent ducting was completed at the time we placed the order for the new popup outlets, so I could switch over to that task while I waited. Unfortunately it wasn’t quite right, requiring a trip back to the fabricator.

In the first image in this post, notice that there is no longer a cabinet above the cooktop countertop. I removed this because I needed to take it with me when I returned to the fabricator so they could see exactly what the ducting needed to fit into. I should have done this in the first place, but I hated to have to remove the cabinet. In the end, it was the right thing to do, and they got it right when I did.

Above you can see the cabinet back in place and the new custom ducting in position. Here it is after I secured it in place.

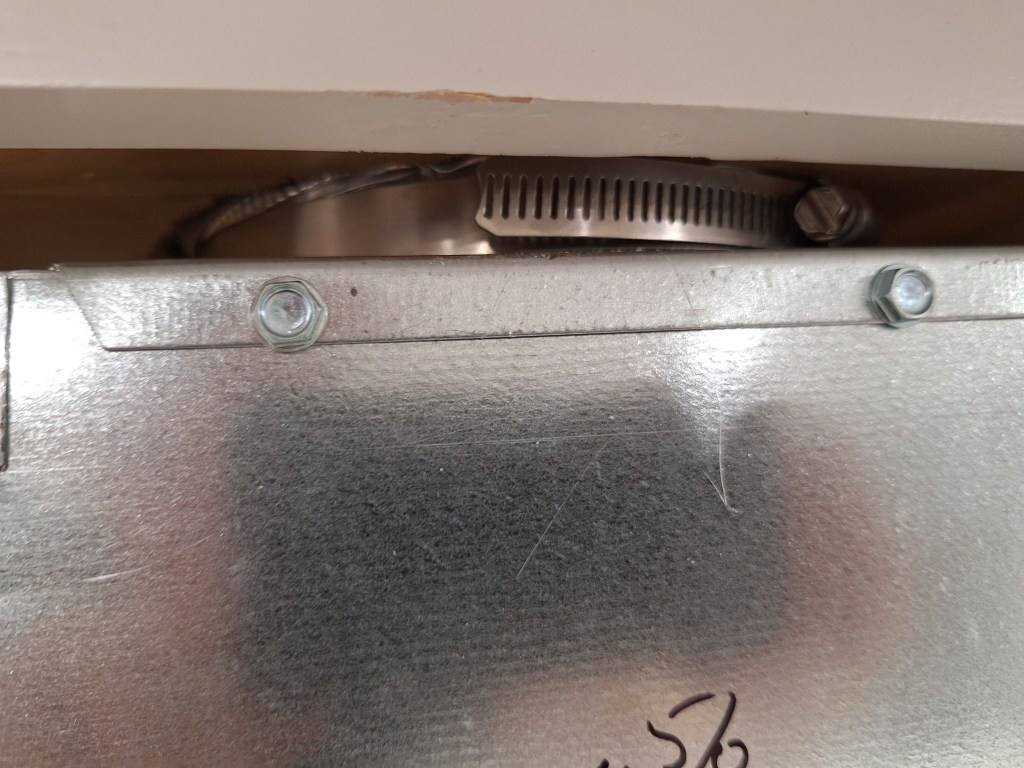

The wood underneath the ducting was placed there just for extra support. The outlet of the ducting is tied to the flexible pipe that extends out the top of the cabinet to the roof. It is secured using a metal hose clamp, as shown below.

This turned out to be a much bigger challenge than I ever imagined. It was a tight squeeze, so I was very relieved that it worked out.

With the ducting secured, it was time to lift the exhaust vent into place and secure it to the bottom of the cabinet with four screws. I had a couple of friends help with this.

Getting that done was a big deal. I was so happy to have it checked off.

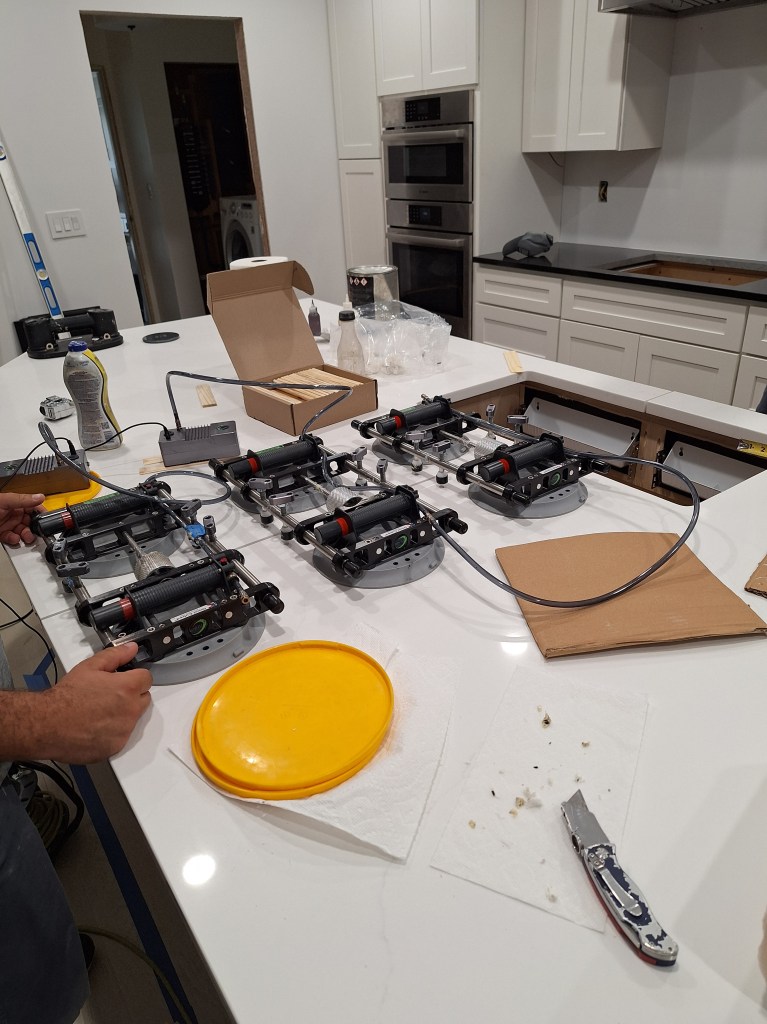

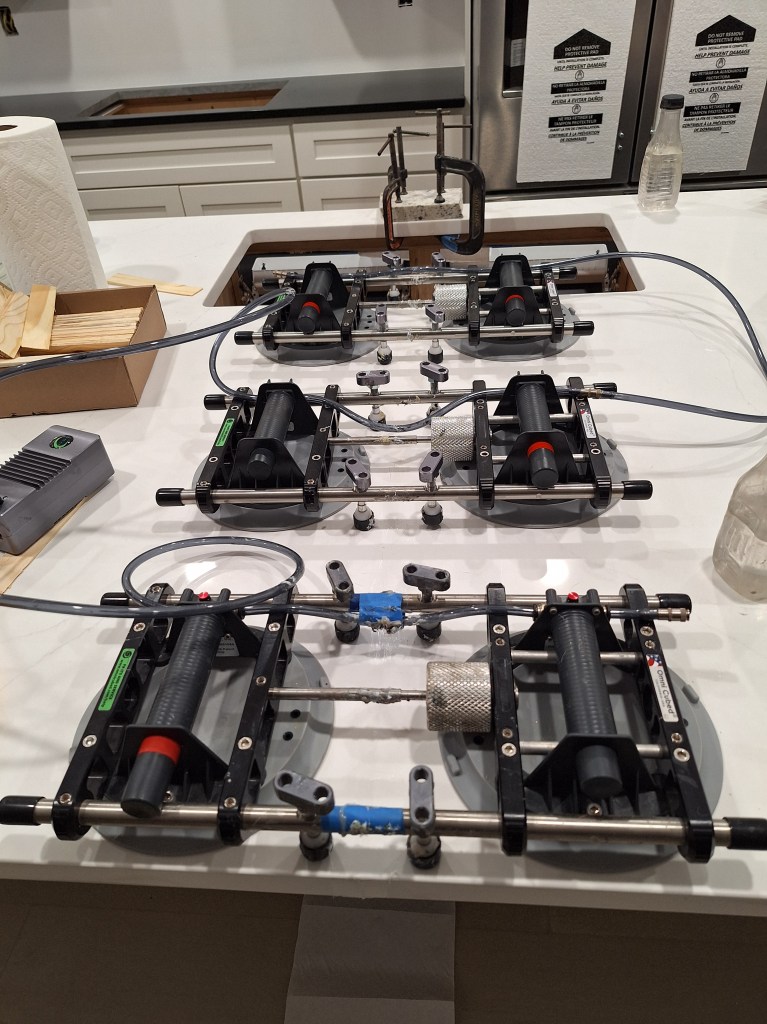

The next day the larger popup outlet arrived. They ordered a gray one because the white color, for some reason, would take longer to arrive. Since this was just to try it out, the color didn’t matter, so they ordered what would get here the fastest. They would return it once we’d determined if it would work. With the wider popup outlet in hand, the guys got to work widening the hole. To my pleasant surprise, it worked, and we did not have to replace the slab. So the guys could start setting the seam between the two slabs. In the image below you can see the equipment used to pull the slabs together. You can also see the gray popup outlet in place at the end of the slab.

Once aligned to their satisfaction, glue is applied and the two seams brought together and left overnight (Thursday, July 3rd).

The two white popup outlets were expected to arrive on Saturday, July 5th, so there was a day in between, July 4th, that I used to install the refrigerator before I headed out to celebrate Independence Day.

The next day the guys returned to finish the installation, which involved polishing the seams, installing the undermount sink, and cleaning it all up. After they left, I put in the faucet and the pressure switch (to the left of the faucet) that will control the in-sink garbage disposal.

The two white popup outlets arrived the next day and I put them in place and plugged them into the outlets below the cabinets.

Note that these outlets also provide USB ports and can charge a phone by simply setting the phone on top of the outlet, whether popped up or not.

With the countertops and sink installed, I arranged to have a plumber install the plumbing for the sink and install the dishwasher. I entertained installing this by myself, but it would be a complicated install. As I later discovered, this was a good call, which you’ll see shortly. But before that happened, the mirror for the the master bathroom vanity arrived and was installed.

The interesting thing about this installation was that the company insisted that they install the vanity lights. Since the lights are on the mirror, they did not want the customer to mess with it for fear that if they over-tighten them, it could break the mirror. So I was completely hands off for this, which was fine by me. It was a two person job, as you’d expect, and took about two hours. I like it.

A couple of days after the vanity mirror was installed, the plumber arrived and hooked up the supply lines to the sink and dishwasher, the in-sink garbage disposal, and the drains for all of it.

As you can see, there is a lot going on here. We decided to locate the garbage disposal under the large sink because installing it under the smaller one would have meant that the drain from it to the main drain would be too steep a slope. When too steep, the water separates from the solids too quickly, which can result in clogging.

Below I am showing a closeup of the P-trap. The large sink drains through the garbage disposal into the drain under the small sink, where the P-trap resides. The output of the P-trap connects to the main drain that continues under the concrete slab and out to the street sewage system. Behind this you can see a black box plugged into the outlet. Into the black box is plugged the garbage disposal. This black box connects to the pressure switch above the countertop (shown in a previous image above), which, when pressed, switches the garbage disposal on/off. The plug below and to the left is for the kick plate lighting, which was discussed in a previous post.

Below you can see the where the drain emerges from below the cabinet. At the top of it is a Studer Vent. Plumbing vents act as pathways for air to enter and exit the drainage system. This helps maintain balanced air pressure, preventing a vacuum from forming that could hinder water flow and cause drainage issues. They are normally inside a wall cavity and extend out through the roof of the house. Since this is not available in an island, the Studor vent comes to the rescue. It provides the venting function while preventing sewer gases from escaping.

You can also see below that a water hammer arrestor (the copper thing) is installed along the water supply like for the dishwasher. This is needed because the dishwasher will turn the water on and off suddenly, which can result in “water hammering”. So this device will prevent that.

Finally, here is the thing everyone sees; the dishwasher.

With this done, I have a functioning island. The last thing required to make the kitchen fully functional was the installation of the cooktop. However, before that could be done, I needed to add a backsplash on the wall behind where it will go. I intended to add white tile with black grout to that area, but after a warning from the tile supplier about how difficult it will be to keep clean I decided to abandon that plan and instead extend the black granite up the wall. There is likely to be a lot of splatter on that wall, and granite with no grout lines will be much easier to clean. That decision, however, meant that I would not be installing the backsplash anytime soon. The granite will have to be sourced, and the fabricators will have to do their thing, etc. The backsplash, however, is not something that requires an inspection, so I went ahead and installed the under counter lighting, cooktop, and outlets in that area so that I could schedule an inspection.

As you can see, the outlets are black, so they will blend in with the black granite once it is placed on that wall.

I ordered the cabinet pulls for the kitchen. The ones I liked were surprisingly expensive, but I got them anyway. Apart from installing the backsplash and cabinet pulls, my work in the kitchen was done, for now. My inspection was scheduled for Monday, a few days from now. So I turned my attention to the guest bathroom, installing the shower head and wand.

There is a bit of a story with this. Both the shower head and wand have separate water supply lines. Each line connects to a “bent ear elbow” behind the wall. When I positioned the two elbows, I estimated where they should go. Unfortunately, I set them back too far, meaning the threads for both the shower head and wand holder could not reach them. This was not an issue for the shower head because I was not keen on the rain shower head I had purchased. It was kind of fancy and attached to the wall with an extended version of the holder for the shower wand. More than that, though, I wanted a shower head that was not limited to just a rain head. So I decided to replace the one I had with one that had both a rain and a traditional stream (achieved by rotating the shower head). This also came with a traditional shower arm, which meant it would easily reach in and connect to the recessed elbow. It was not a perfect color match, but close enough.

However, there was no such option for the wand. The threads of the wand holder were not long enough to reach the threads you see in the image below.

To fix this, I purchased an adapter to bring it out to the level of the tile. In the image below, you can see that it actually comes out just beyond the surface of the tile, but this is well within tolerance because the flange for the wand holder would cover it.

Unfortunately, the threads of the wand holder were too long and, when fully seated in the adapter, the holder extended too far to be covered by the flange.

As it was, this was unusable and looked like I’d have to replace it. After some thinking, I decided to try cutting off some of the brass threads. Since I figured I was going to replace it, I might as well give it a shot. So I pulled out a hack saw and sawed off a section, careful to keep the threads in tact.

Although it looks a bit messy, I didn’t have to do any work with a file to clean it up. The threads engaged nicely with the threads in the wall, resulting in a nice fit. It protruded just a bit, but that was easily covered by the flange, as you can see in the image below.

I was pretty happy about this. I thought this was going to be a major headache. To have it come together like that was very pleasing.

My cabinet handles arrived, so I got to work installing them. I installed all but the ones that will be going on the cabinet doors that I am having replaced. A few of the doors had defects. Given that there is a 5 year warranty, the company has been notified and they will eventually send me replacements. So in the images below where no handles are present, those are the doors that will be changed out once the new ones arrive.

Note that on the other side of the island there are also cabinet doors, but they will not be getting handles because those cabinets will rarely be used and adding handles might present an obstruction for ones knees while sitting at the counter. They can be opened by pulling on the bottom edge of the door, when needed. Also, from the vantage point of the living room, I think it looks better without them.

My inspection resulted in the approval of the electrical and mechanical. The plumbing and final inspection had to wait because the inspector had trouble finding the stamp on the glass wall of the master shower that shows it is tempered glass. That was resolved the next day, so I scheduled another inspection, which resulted in the approval of what was remaining. So I am finally done with inspections, which is a really big deal. I am free to move in when I’m ready and can proceed with whatever project suits me without regard to permit expiration dates.

The lease on my apartment ends mid November, so I will use the time between now and then to work on anything I feel I’d like done before I move it. However, I am at the point now where I could move in because the remaining projects are ones I can and will do while living in the house.

The timing of this worked out well, as I am going on vacation for about ten days. So it’s a nice way to start that. When I return, I think I’m going to focus on the garage and setting up the workshop I need to address the upcoming project. That will be fun.