Guest Bathroom – October 2024

Having made the master bathroom functional, it was time to get started on the guest bathroom. This was the last room in the house that had been untouched since the demolition long ago. I left this room until last because it was where the only working toilet and sink resided. Now that the toilet in the master bathroom is functional, the one in the guest bathroom was no longer required. Similarly, with a working utility sink in the garage, I had an alternative to the one I had temporarily installed in the guest bathroom. Still, I wasn’t planning to remove either of these appliances until absolutely necessary.

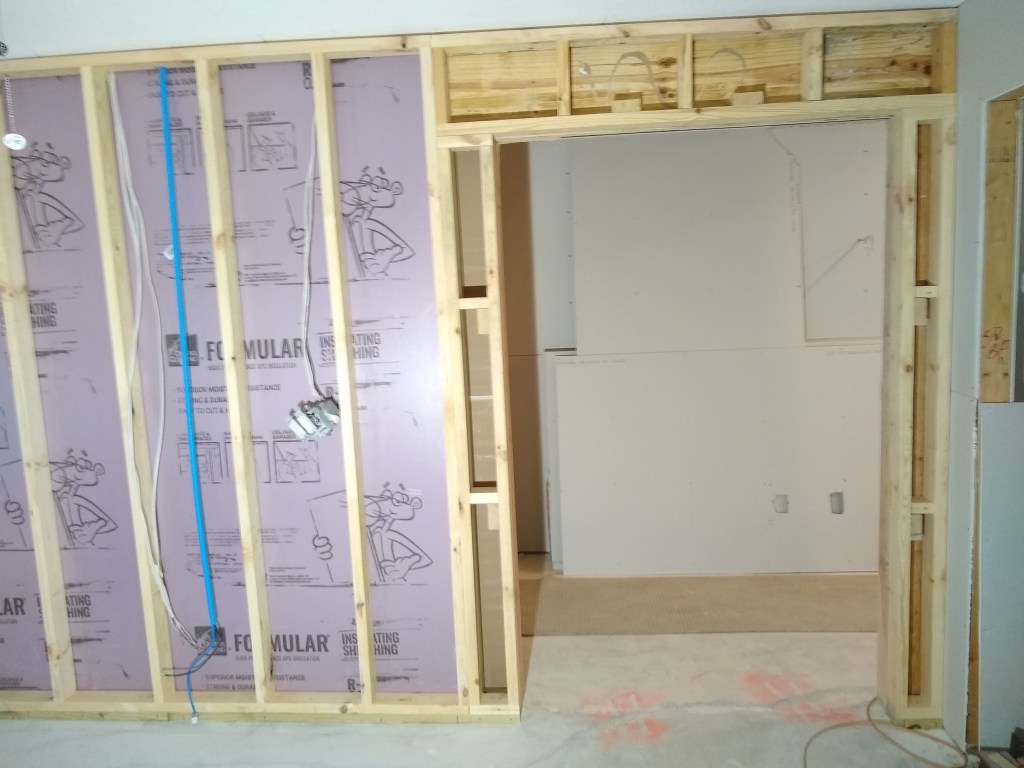

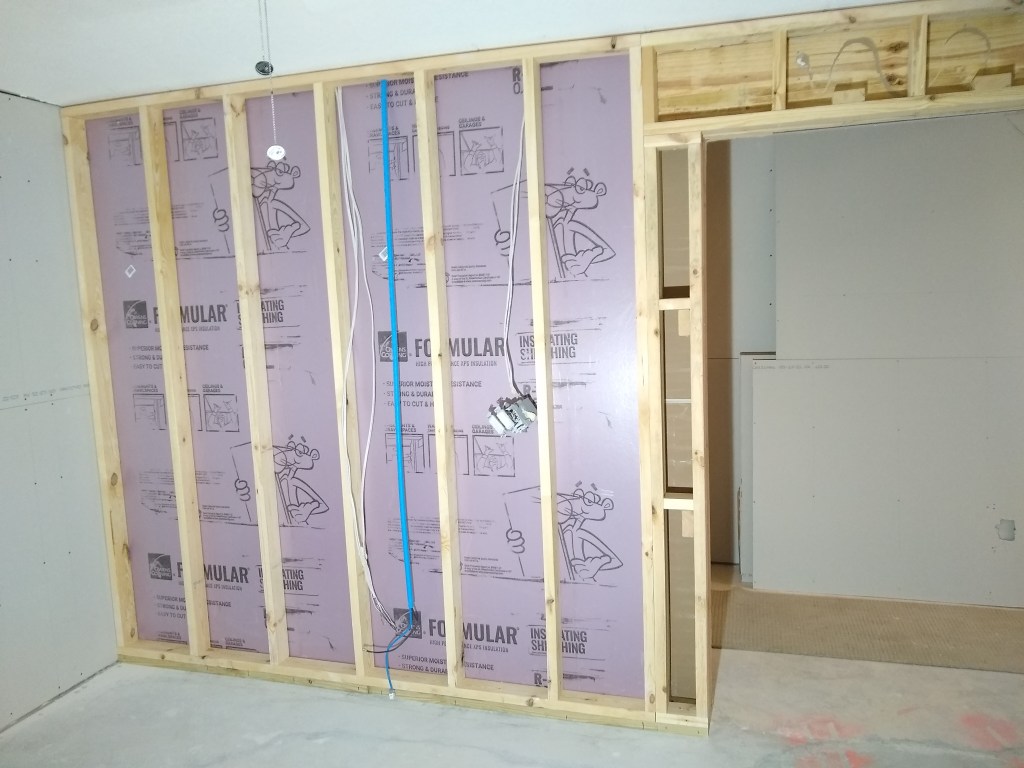

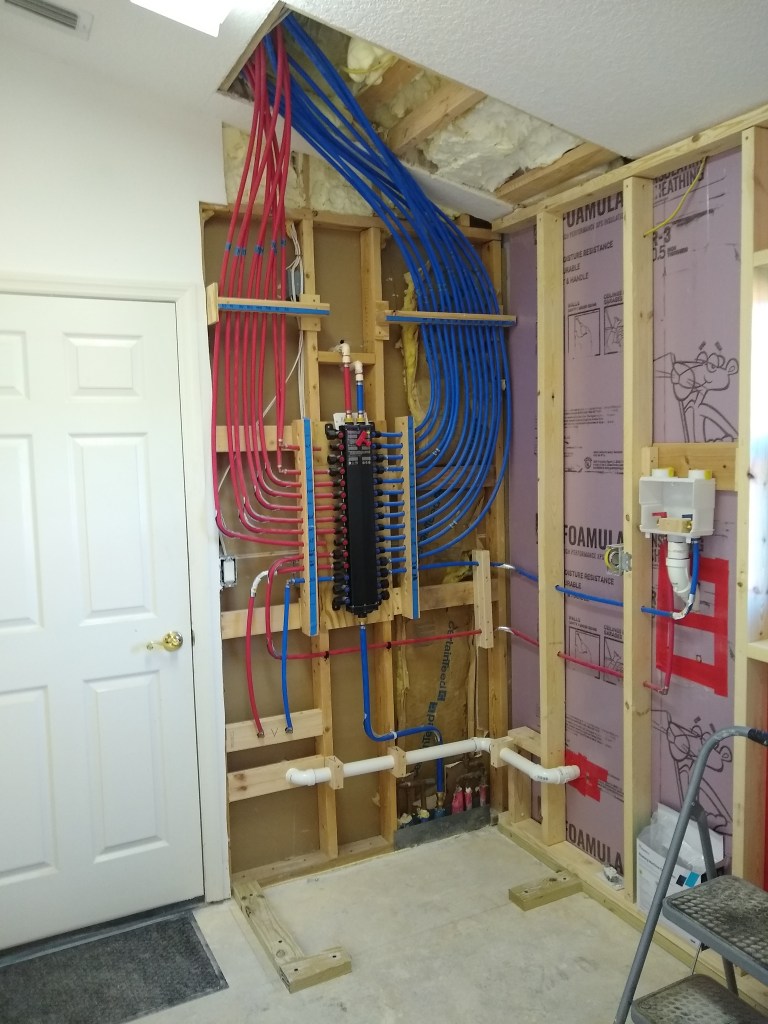

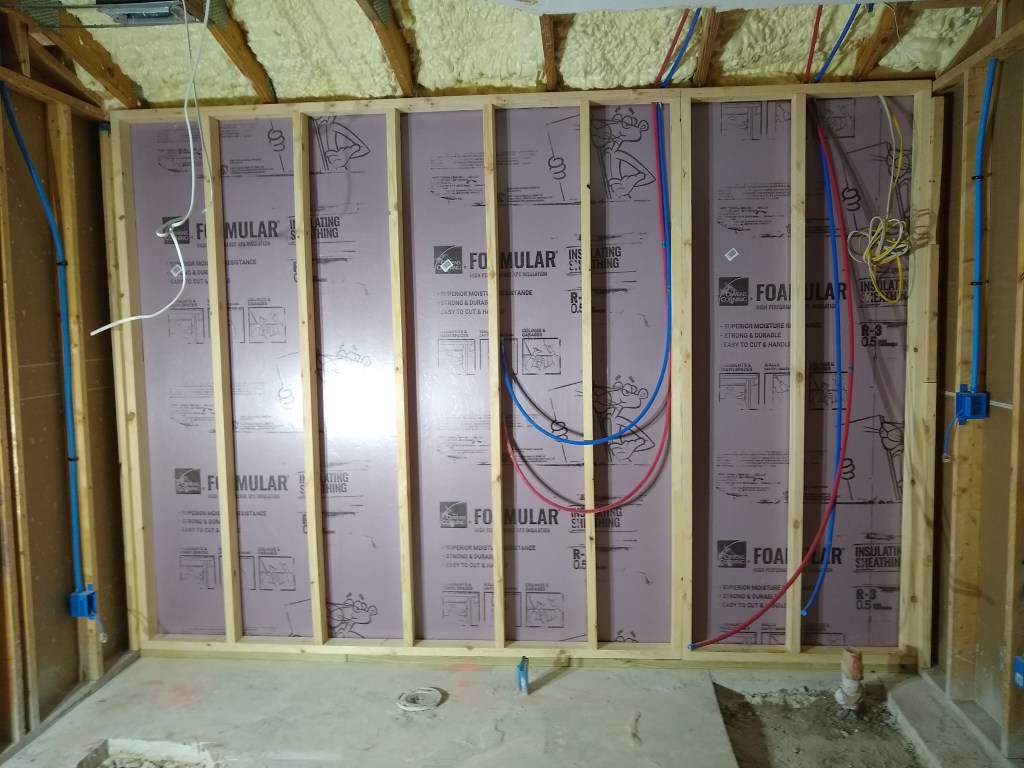

The first thing I did after cleaning out the space, was to relocate the shower supply lines. I put them in place back when I was running the PEX throughout the house, and simply placed them on the wall where the original pipes had been. You can see this on the left side of the image below.

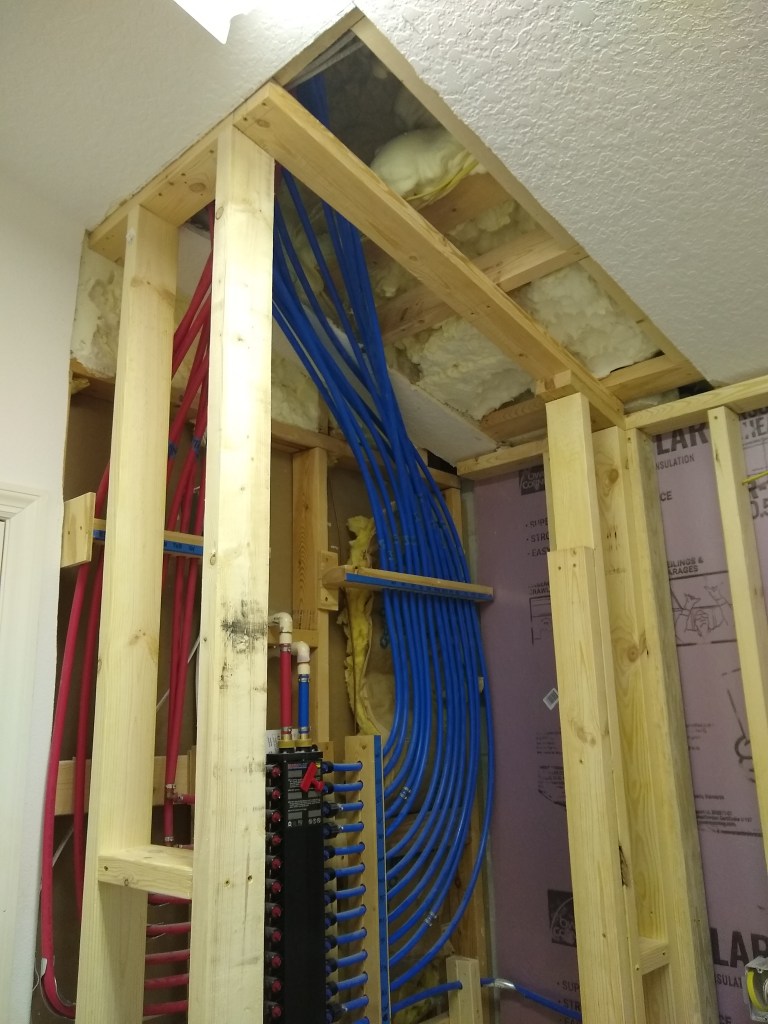

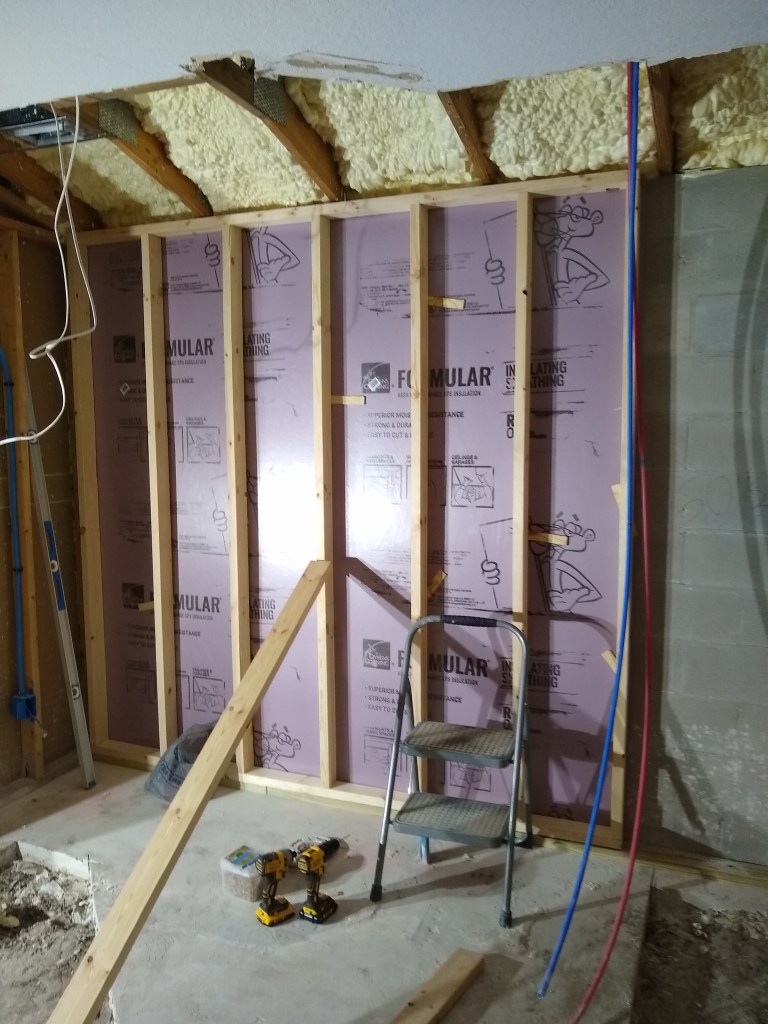

This bathroom originally had a bathtub/shower setup, so it made sense for the valve to be on that side of the wall. However, I no longer wanted a bathtub. All I wanted was a walk-in shower, with a curb. This meant that it made more sense to locate the valve, and therefore the supply lines, to the opposite wall, where you could set the temperature without having to be in the shower. To accommodate that, I pulled down some of the ceiling.

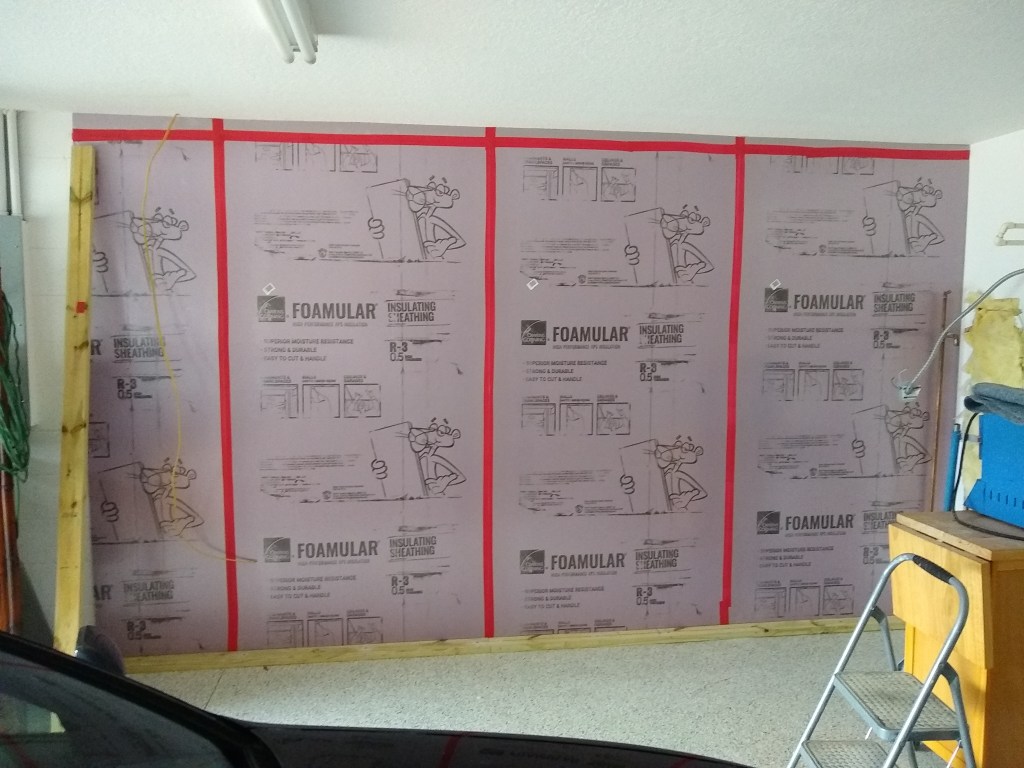

As you can see, there is a lot of spray foam up there, leaving little room to maneuver the PEX pipes. Opening up this area made this much easier, and I didn’t have to climb up into the attic to do it. In the image above, you can see the two supply lines dangling down from the ceiling on the left, which is the south wall. They will be fed down through the top plate of that wall once the framing work is done and I know where I will be placing the valve. But before that, I placed some foam board insulation against the exposed concrete blocks.

Next, I removed the toilet in order to get greater access to the shower area. It was a bit sad to remove the toilet because it worked flawlessly for so long. It had been my only working toilet since I started this renovation and it always just worked. I never even had to change the flapper.

With the toilet no longer in place I removed the last of the drywall and tile that that surrounded it.

The original toilet flange held up well. It was set in place more than twenty years ago. It will be replaced.

I removed the toilet flange using a pull saw. This worked extremely well, leaving the flange barrel flush with the floor. I stuffed a towel down the drain to prevent any debris from falling in.

The barrel of the flange was removed by using my reciprocating saw to make vertical cuts, being careful not to cut into the drain to which it was glued, then chipping it out using a screwdriver. This was much easier than I expected. The pieces broke away easily.

With the toilet removed, I had room to install the shower curb.

This being a much smaller bathroom than the master bathroom, a curb makes sense here to contain the water. In anticipation of the glass wall and door that will enclose the shower, I added additional framing on either end of the curb.

The curb is made from pressure treated lumber. Since it will be covered in a water proofing material, only the wood touching the concrete floor needed to be pressure treated, but I chose to make the entire thing from the same material. To the right in the shot above, you can also see that I temporarily covered the toilet drain with a flange and plug to make sure nothing falls into it. This flange will not be the one I use in the end, because it is too small, but it serves as a protective cover for now.

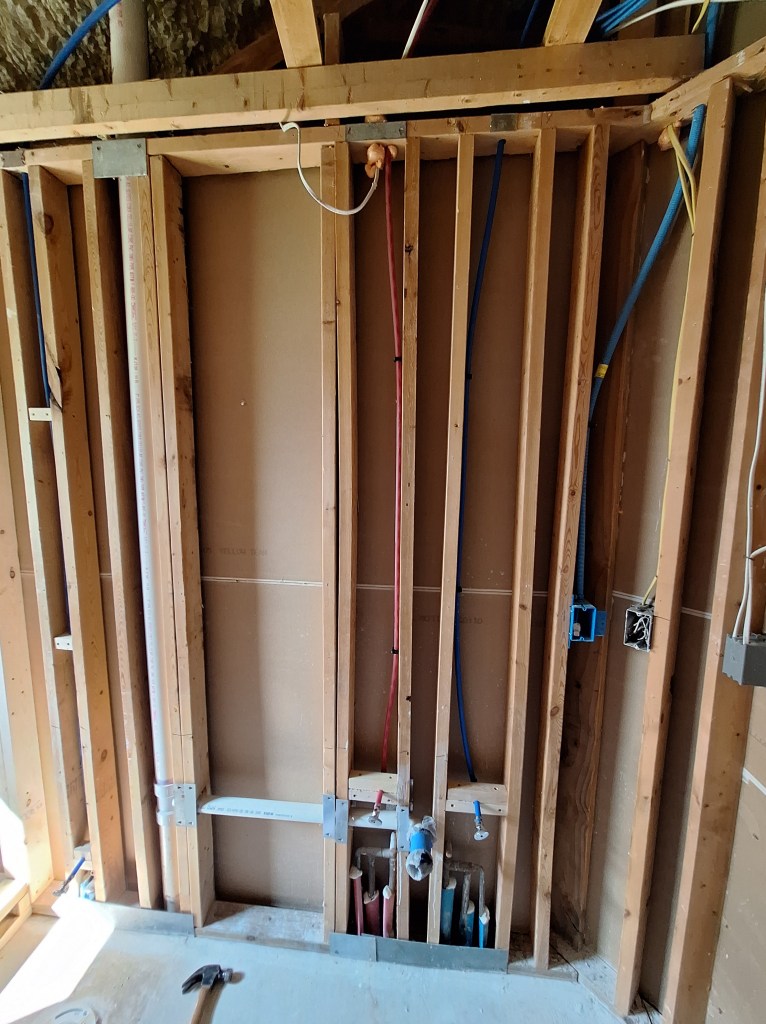

Next, I installed the shower valve.

As you can see, in order to position the valve centrally on that wall, I had to cut a notch in the center stud to make room for it. I also added another stud along the outside wall in order to provide more area to attach the waterproofing board (Kerdi Board).

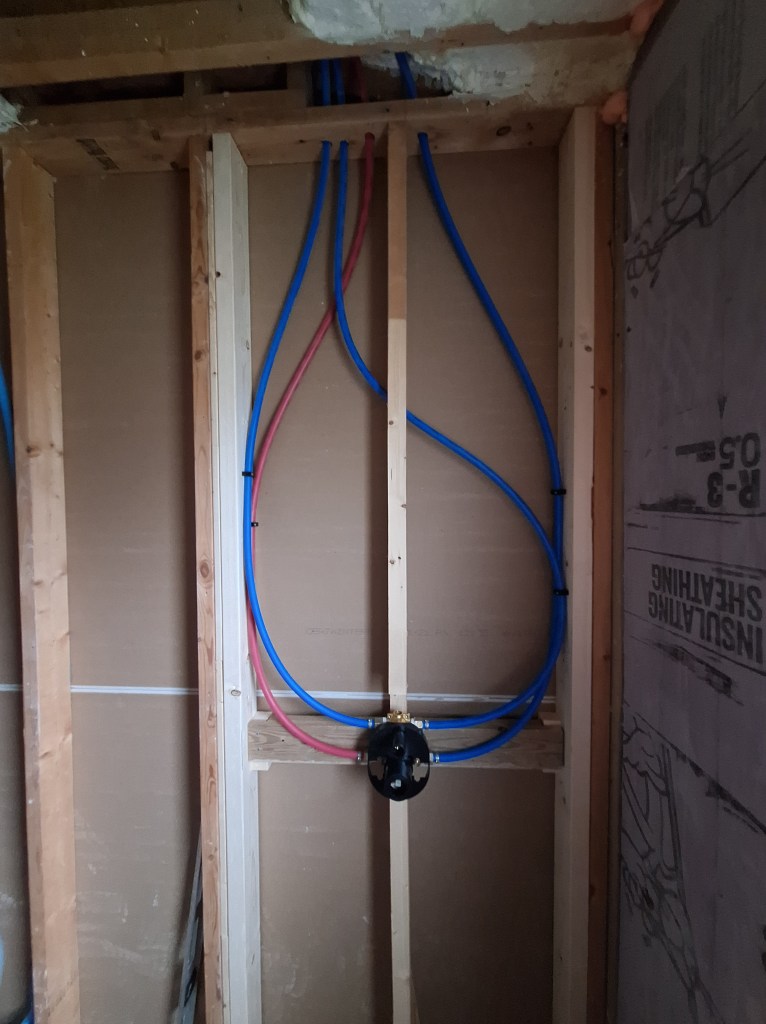

I brought the hot and cold supply lines down through the top plate, but it was extremely tight, especially for the cold line (blue). The two lines that leave the valve and travel overhead to the opposite wall would have to be done in a more round about way.

Given the tight spacing, I had no choice but to run the two traveler pipes to the valve as shown below.

I also made a change to how I brought down the two travelers to the drop ear elbows.

If you look a couple of pics up, you’ll notice that I originally ran the two lines down the preexisting holes in the top plate. After deciding where to place the blocking for the shower head and hand held wand, I moved them to more directly align.

With the supply lines in position, I started looking at the drain situation. Since there was a tub/shower in place before, the drain needed to be replaced with one suitable for the shower, which meant pulling out the existing 1-1/2″ drain and installing a 2″ drain, as required by code.

Below you can see how the fitting I just removed has an inlet for the drain and another for the overflow drain of the tub. The remaining stub goes down about 12″ to the bottom of the p-trap.

Below I show the new arrangement that will tie into the remaining stub.

As you can see, it sits way too high. This is made even more clear when the drain itself is added.

Even after the shower pan is added, I would still have to lower the stub by close to 8″ to accommodate this, which meant cutting out the concrete at the bottom of the box. It also appeared that once the drain flange was added and this whole assembly was lowered, it would come into contact with the front of the box. So the front edge of the box would have to be chipped a way a bit to make room for it.

I began by using my angle grinder to score a series of lines as deep as it would manage. After that, I used my small jackhammer, and the pieces broke away quite easily.

I continued in this way until I had cleared away everything around the existing 1-1/2″ riser pipe.

Next I removed the dirt from around the pipe until I reached where it connected to the p-trap. I wanted to go as low as possible and still have something to connect to. Once the dirt was removed, I placed the dry fitted assembly roughly in position to determine if I needed to expand the front edge to accommodate the drain flange. As expected, I did have to expand it, so I chipped away only enough to make room for the flange.

After that, I used my inside pipe cutter to remove all but an inch or two of pipe above the p-trap fitting then added a long sweep 90 degree fitting.

Then the remaining pipes could be added, which included a short 1-1/2″ connector to a reducer bushing that would fit into another long sweep 90, but this time with a diameter of 2″, as required.

I kept the 2″ riser long so it can be cut to final height after the shower pan is in place, just like I did in the master shower. Once given the okay from the inspector, this area will be ready for a concrete pour to lock it in place.

Reluctantly, I removed the utility sink. I had intended to keep it in place as long as possible, but now I was ready to check the walls for flatness and add shims where needed, and the utility sink was in the way. Also, I was ready to schedule a plumbing rough-in inspection, so I needed it out of the way so the inspector could see the drain situation behind the sink. Here are a couple of shots after I removed the sink.

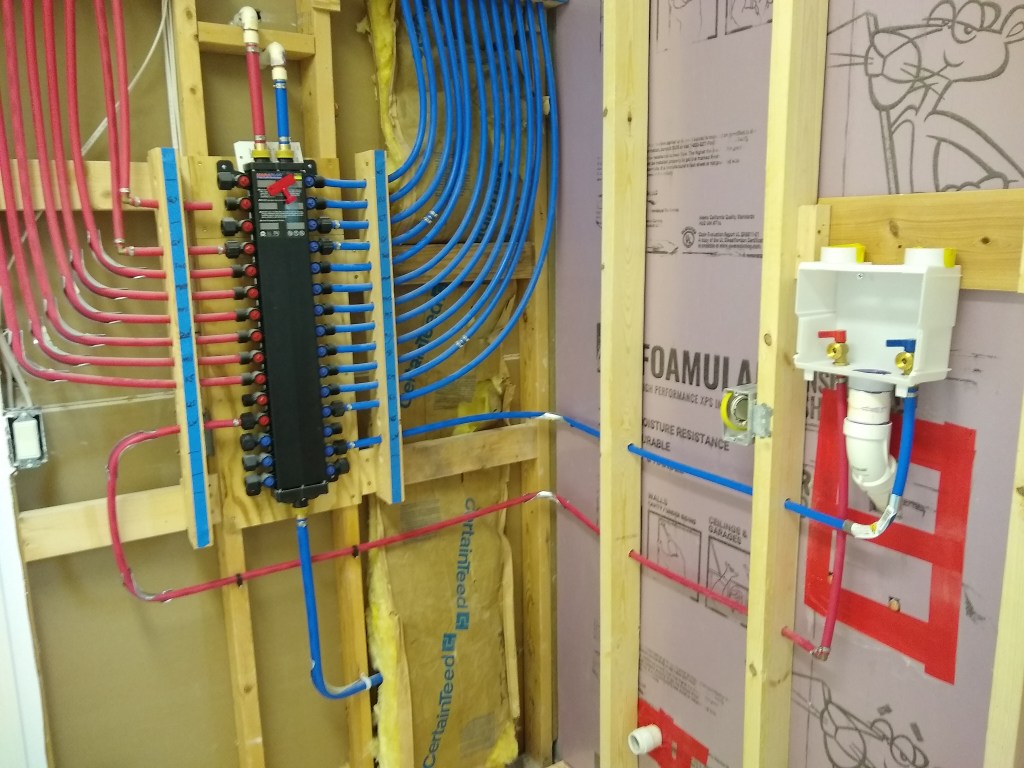

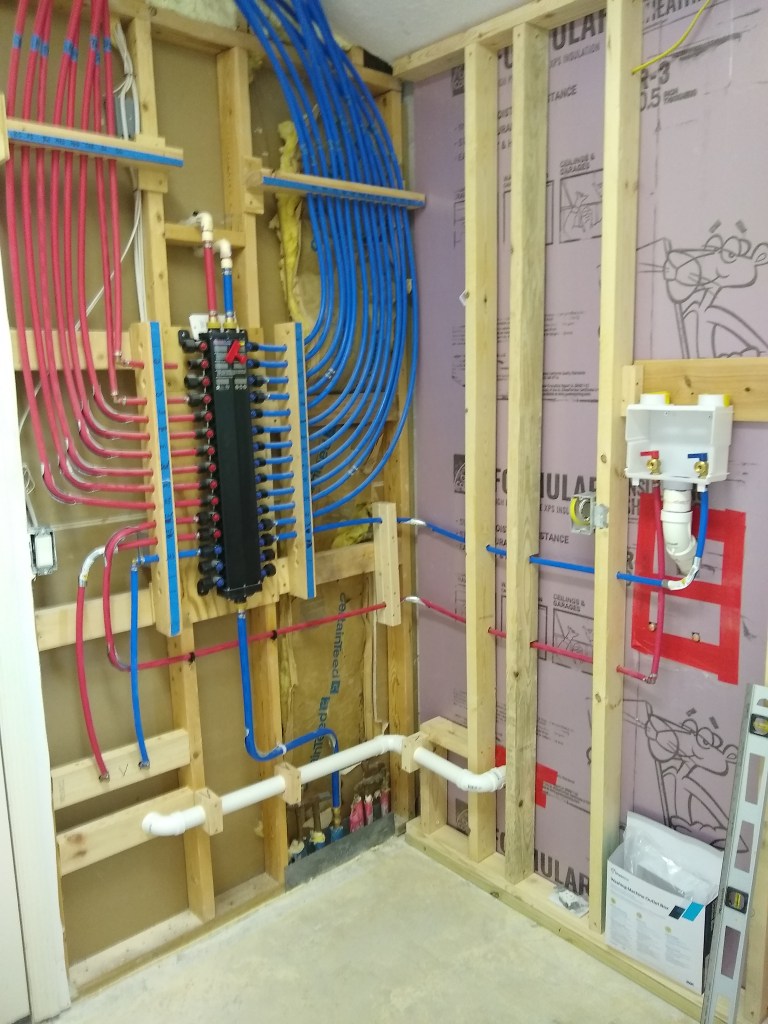

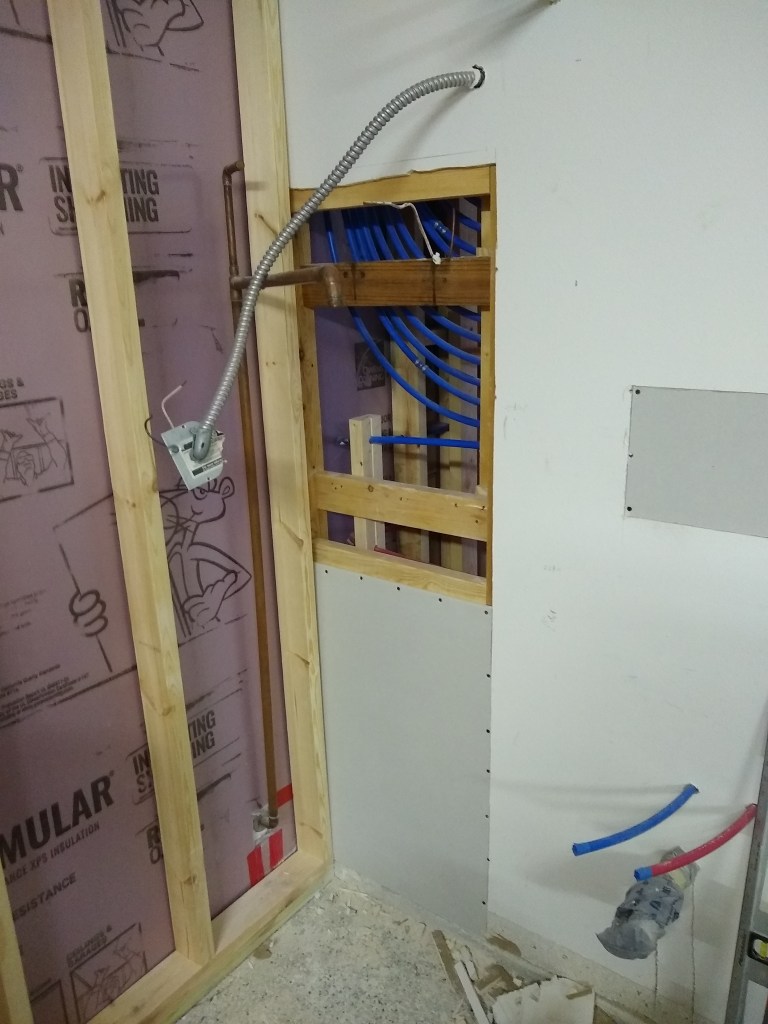

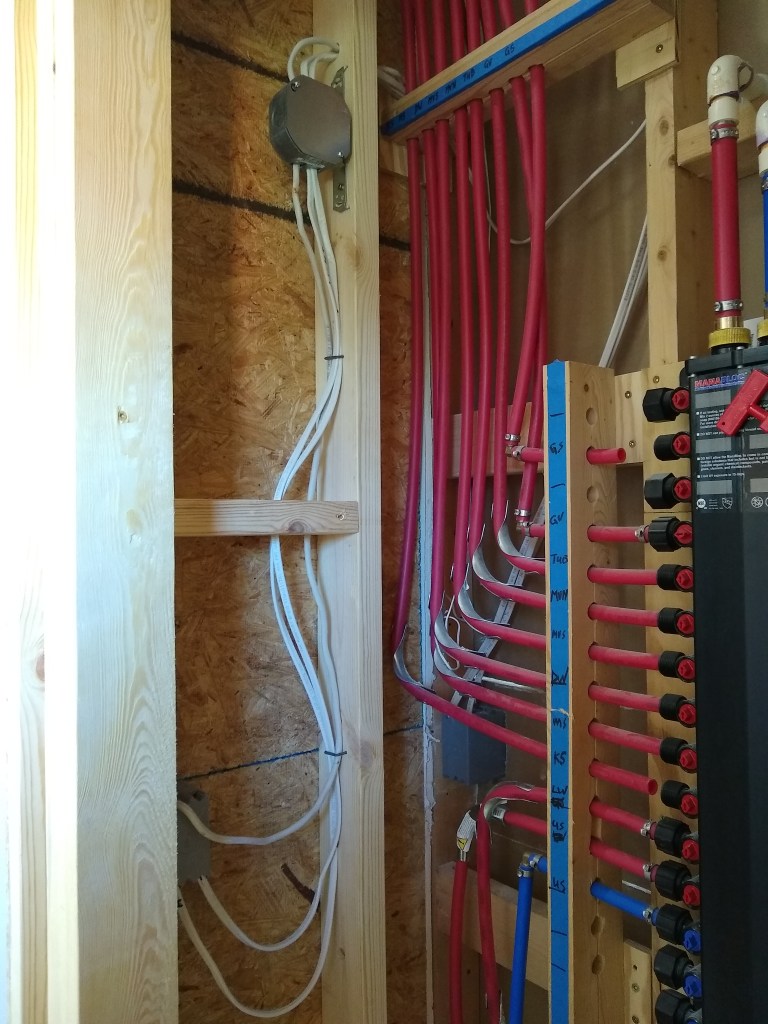

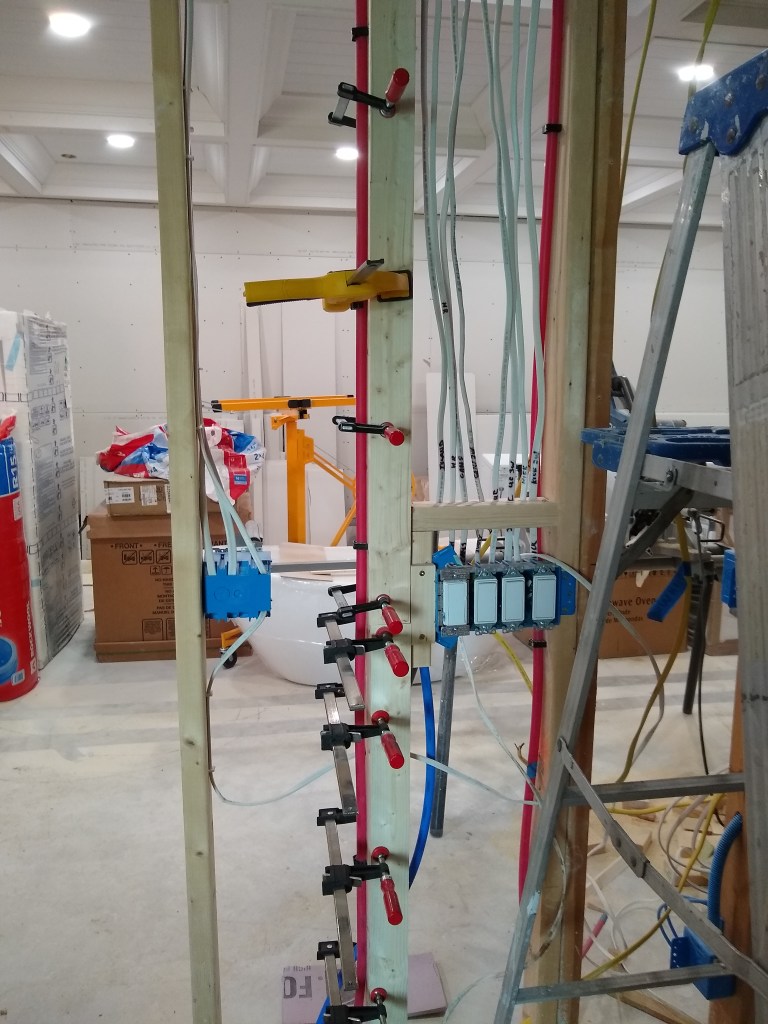

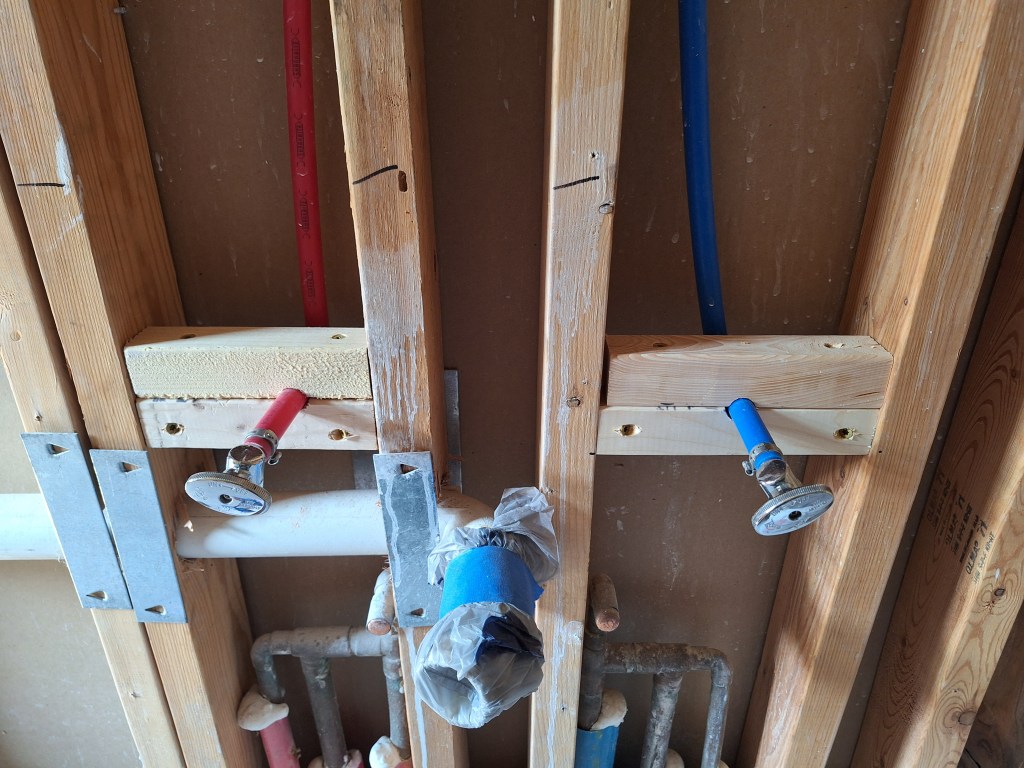

With the area cleared, I began securing the supply lines. I used plastic clips to secure them to the studs.

Where they emerge from the wall cavity I added a 90 degree PEX fitting (hidden behind the wooden clamps) and secured them with homemade clamps. These worked very well and allowed me to position them between the studs where I want.

Due to the limited space between the studs where the toilet supply line ran, I could not use the plastic clips to secure the PEX pipe, so I made my own, as you can see below.

With that done, the inspector came by and approved my work, meaning I was now free to cover it all up. For the ceiling and walls, this would mean putting up drywall. For the shower, this would mean Kerdi board. It also meant I could fill in the shower drain pipes with concrete. In preparation for that I added back the dirt I removed and added some TapCon screws to serve as mini rebar (as suggested by the inspector).

Since the area around the drain pipes is quite small, no rebar is really needed, but adding a few screws only took a few minutes, so why not? Later in the process I poured concrete to cover part of the opening. I left the area around the riser pipe open as the under side of the drain will need that space.

Before putting up drywall, I also wanted to add additional blocking where I thought it might be helpful. I added another stud to the outside of the shower curb to serve as a nailer.

These nailers were added because this will be the junction between the Kerdi board and the drywall, so I needed something for the edge of the adjoining drywall sheet to screw into. I also added an additional stud to the inside corner between the entrance wall and the vanity wall (shown below), which is angled at about 45 degrees. Originally there was nothing there for the drywall to attach to, which is probably fine given that it would receive no stress, but since the walls were open, I decided to add it to make the inside corner more secure. Notice how I had to notch it in order to make room for the Ethernet conduit.

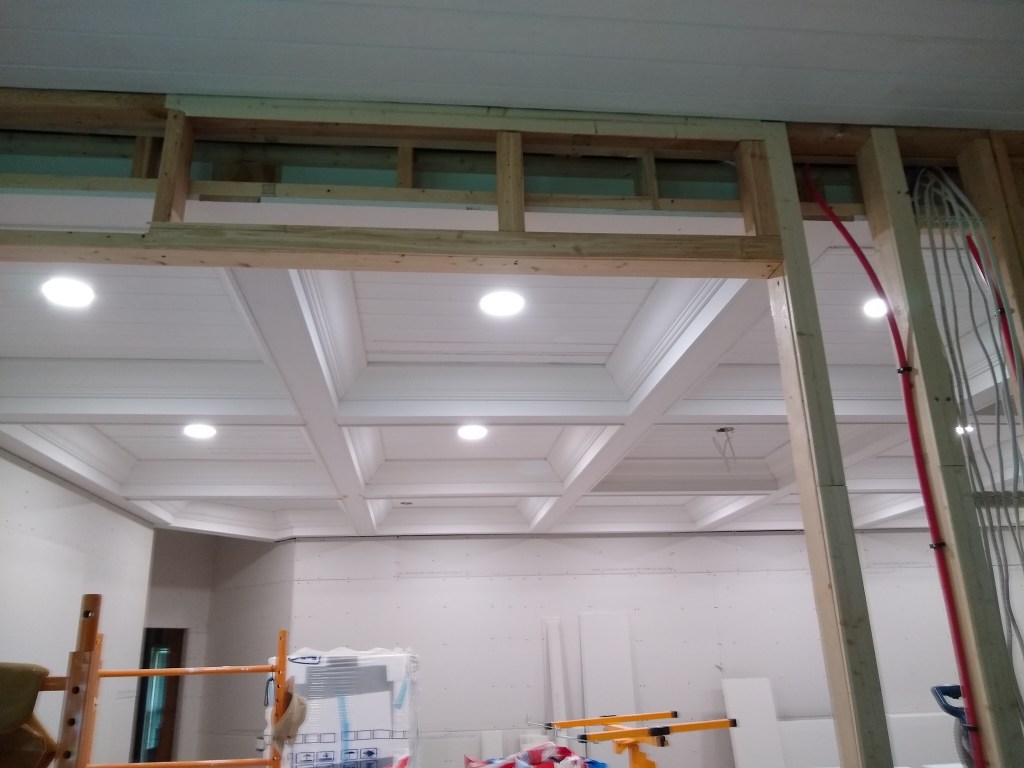

I decided I would replace the original vent fan with a new one that would also have a light. This meant I would have to replace the wiring to the fan from a 14/2 gauge to a 14/3 so that the vent and the light can be controlled by separate switches. As a result, I decided to pull down the remainder of the ceiling. You can actually see evidence of this in a couple of the shots above. With the ceiling opened up, I was able to create a custom opening for the new fan/light, as shown below.

One of the nice things about doing it yourself is that you have the ability to customize and even change your mind. Although this bathroom has a window in the shower area, I thought it would be a good idea to introduce a fan with a light so that you are not depending solely on the vanity light at night time.

Since I didn’t have quite enough 14/3 wire to reach the fan housing, I had to splice two separate lengths together, which required a junction box.

With no switches in place, I tested the fan and light by temporarily connecting the neutral and ground wires and then manually bringing the hot wire in contact with the wire to the fan and then to the wire for the light.

One of the lessons I learned from doing the master bathroom was the importance of having flat walls. The walls in the master shower were flat, but the wall behind the vanity was not, so I had a lot of “mud framing” to do to get it close to flat. This could have been avoided if I had paid more attention to the flatness before the drywall went up. So this time I paid close attention to make sure all the studs were aligned, and planed down those that stuck out and added shims to those that were recessed. It’s a nuisance, but well worth it when it comes time to finishing the walls. I also added blocking at the bottom of the walls where baseboard with be added.

The shims are thin strips of cardboard layered on top of each other. Using this material made it easy to fine tune. Also, notice that I added blocking for the other side of the wall too, which is the guest bedroom. That wall will have baseboard, so this will make it easier to attach. Unfortunately, I didn’t think of this on any other walls I did, so I’ll have to do it the usual way by searching for studs when nailing the baseboard.

Since there will be very little baseboard along the wall where the vanity will be, I only added blocking for the cabinet to attach to. I did add a piece of blocking for the wall outside the entrance to the bathroom to make attaching the baseboard there a bit easier.

With the blocking and shimming done, I was ready to hang drywall. But first, I had to go get it. And to do that, I used my fancy new rail system I created for the top of my car. Below you see seven 4×8 sheets of blue drywall. The color blue indicates it is water resistant, which is appropriate for a bathroom.

I began hanging the drywall on the ceiling, nearest the outside wall. Since I had already installed the shower curb, it got in the way of my lift, so I could not position it directly under the location I desired. So I added a temporary cleat to the wall above the window, about an inch below the ceiling, and moved the lift as close as I could. I then lifted the sheet almost to the ceiling before sliding it over and onto the cleat, which you can see below.

Once supported by the cleat, I raised it all the way and started securing it with screws. If you look really closely, you can also see that I applied construction adhesive to the joists. I do this with all my drywall to help ensure it does not come loose in an effort to avoid “screw pops”. Here it is after securing it.

The second board was a bit easier, as I was able to position the lift exactly where I wanted it. The final piece was small enough that I did not need the lift.

Before hanging the drywall on the walls, I added sound insulation, as usual. It’s amazing the difference it makes, especially in such a small space. After adding the sound insulation, the room just feels solid.

And here it is covered with drywall.

When cutting out the holes for the water supply lines and the drain, something happened that really annoyed me. I hung the top sheet first; the one that touches the ceiling. That went well. The sheet below it is the one where I had four round holes to cut in order to make room for three water supply lines and one drain. I was carefully measuring their locations, referencing them from the edge of the drywall that touches the curb and the lower edge of the top sheet I’d just hung. My measurements were aimed to locate the center point of the cut (I used a drill and a hole saw to make the cuts). I cut the three supply line holes first, then switched to a slightly larger hole saw for the drain. After making that cut I pushed the sheet against the wall and everything fit perfectly except the hole for the drain. Then I realized that after being so careful with the other ones, I made a silly mistake when measuring for the drain. Instead of measuring down from the top sheet to the center of the drain, I measured to the top of it. So that is why you see a sizable gap above the drain. The other holes will be covered by flanges, but I’ll need to do some repair work on the hole around the drain. Even if I could find a large enough flange to cover it, I will still want to improve the situation.

I scheduled a drywall inspection, which is required before I start taping. While waiting for that, I started work on the shower area. I was about to start putting up the Kerdi board on the exterior wall when I realized that the thickness of the Kerdi board (1/2″) plus the thickness of the furring strips (3/4″) attached to the concrete block wall was less than the length of the screws (1-5/8″). I needed at least another 3/8″ to avoid hitting the concrete block. This was not a problem in the master bathroom because all the walls surrounding the shower were interior walls, meaning there was 3-1/2″ of stud to drill into. Rather than add to the thickness of the furring strips, I decided to use the extra drywall I had, which was 1/2″ thick, and attach it to the furring strips. It came out like this:

This worked really well and I loved that I was able to make use of the extra drywall. Since this would all be hidden behind the Kerdi board, there was no need to tape it. All the lines you see drawn on the drywall are there to identify where the underlying furring strips were located. This would be needed when attaching the Kerdi board, which you can see below.

One of the consequences of having to build out the exterior wall, was that I was reducing the space within the shower. It was already a bit tight, and I didn’t like that I was making it tighter, even if only by 1/2″. So I started entertaining moving the curb over one stud. Recall that I added an extra stud on the outside of the curb to serve as a nailer for the drywall. I could shift the curb to align with this stud and gain an extra 1-1/2″. But it was not as simple as that because I also had to take into account the distance between the toilet and the curb. The curb was initially located 15″ from the center of the toilet flange which, from what I read online, was what you want in order to provide enough elbow room. Moving the curb out by 1-1/2″ would reduce that space. However, what is more important is the distance from the center of the flange to the glass wall that will sit on the curb; the thing that will impact your elbow. The glass wall will sit in the middle of the curb, which means I’ll get back to the 15″ I wanted. So I was comfortable pushing the curb out to widen the shower space.

While thinking this through, I did a bit more research on the Schluter curb product. The Kerdi curb is something you attach to the floor using thin-set mortar and is covered with a waterproof membrane, just like Kerdi board. It is strong and can support a glass wall/door. The benefit of switching to this, is that it doesn’t need to be screwed down to the concrete floor, giving me more flexibility when positioning it. So I can keep the area open until I absolutely have to put it in place. One less thing to step over. Below you can see the remainder of the Kerdi board in place and the curb removed.

Next, I prefilled the drywall, then taped.

I also added Kerdi band to the seems and to cover the screws in the shower.

I left the screws around the window and near the floor uncovered because they will be addressed when I add the shower pan and waterproof around the window. Next will come the cover coats to the drywall. I don’t plan to do anything on the floor (i.e., shower pan) until the walls and ceiling are at least primed. Since this is the last day of October, I’ll close the post here and continue in the next post.