Hot Water Tank Installation and Major Painting – June/July 2024

While waiting for the shower wall tiles and extra floor tiles to arrive, I decided it was a good time to hook up the hot water heater and install a utility sink in the garage. My original plan was to use the existing hot water heater, since it wasn’t that old. Here is the only shot of it.

This was a 50 gallon hot water heater that was in place before I started this project, when I drained and disconnected it, with the intention of reusing it. Although it was only a few years in use, I removed the pressure relief valve that is located on the side of the tank to have a look at it and replace it (something one should do from time to time). I saw quite a bit of scale on it, which caused me to rethink whether it was a good idea to reuse the tank. I did not want to go through the trouble of hooking it up only to replace it not long after. So I purchased a new one. This time I got a 40 gallon tank, since that should be plenty for my needs and those of any guests I might have. Here it is installed.

Rather than use 90 degree bends to feed the tank, I used 45 degree connectors for a straighter run. I think it looks a bit odd, but that’s okay with me. An inspection will reveal whether any changes are required. At this point it is working and I have hot water again.

In the image above, you can see that the pressure relief valve is connected to the existing pipe that takes the water outside the garage.

With that done, I installed a new utility sink beside it.

I had intended to reuse the utility sink that came with the house; the one I relocated to the guest bathroom. However, since it was my only source of water, I did not want to disconnect it without having an alternative, so I kept the existing one in place and bought a new one for the garage. I opted for a slightly smaller tub since I am limited in space between the hot water tank and the door (there is still trim to be added around the door). The existing utility sink is 20″ wide and this new one is 18″ wide.

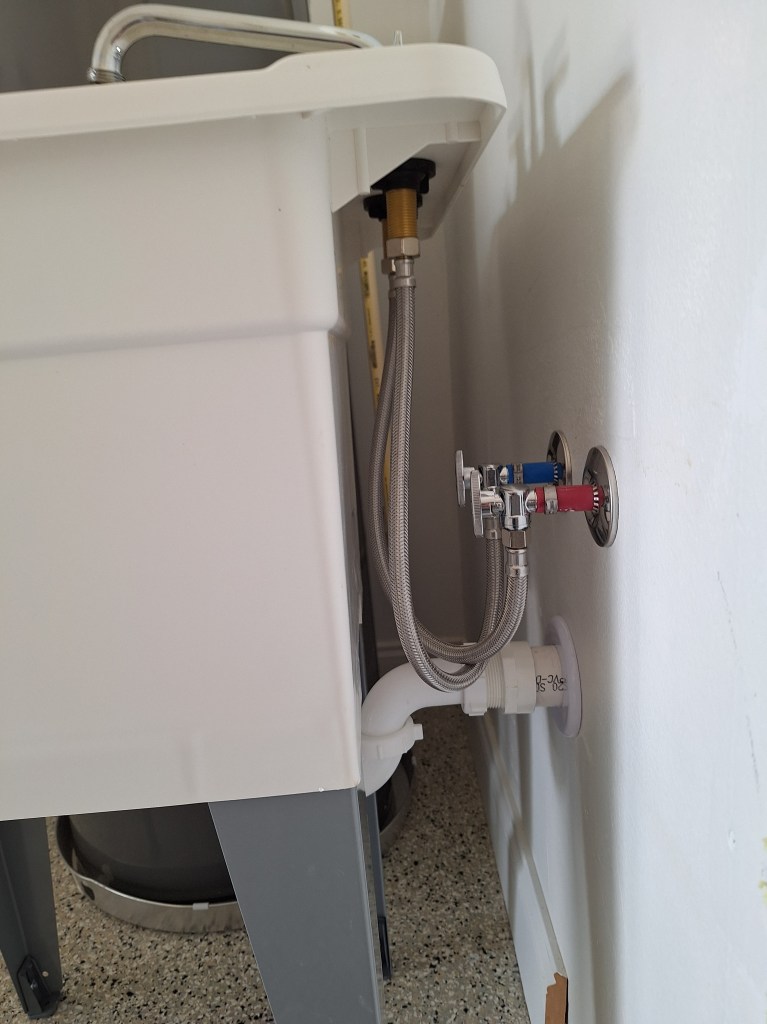

I think the smaller size was appropriate, as it tucks in nicely without looking too crowded. Here is a shot of the hookups.

Notice how the hot and cold lines cross each other. This was a funny little mistake I made when bringing those lines through the wall into the garage. On the other side of the wall they are oriented correctly (hot on the left, cold on the right). I didn’t realize at the time that it would be backward on the other side of the wall. No big deal, and I had a chuckle over it once I realized.

The sink has not yet been fastened to the floor. As with the hot water tank, this will need to pass inspection, which I haven’t arranged yet. I don’t want to secure it to the floor in case the inspector wants me to make changes. So I’ll have to be careful not to jostle it, which can damage the drain connections. In the meantime, it is nice to have hot water and an alternate wash basin to use.

After this was completed, I contacted the place where I purchased my shower wall tiles to get an idea of when they would arrive. To my surprise, it was going to be at least another week, so change of plans. I decided to start painting the ceilings in the great room, foyer, and guest hallway.

These areas had some intricate details, so I decided to use a brush to paint them. When applying the primer, I used both a brush and small roller, but to get a consistent finish, I would use only a brush, which made it a lengthy process, especially since I applied two coats. I used a high quality latex paint with a matte finish – Behr Dynasty Ultra White.

My shower wall tiles arrived after I completed the painting of the ceilings, so I picked them up and set them aside. The master bathroom would have to wait. Having started the painting process in the great room, I decided to push on and paint the ceiling and walls in all adjoining spaces. This meant I would paint not only the great room, but also the dining room and kitchen.

The ceilings in all these spaces would be the same color (Ultra White). The walls in these areas would also be painted, but a slightly different shade of white. Originally I tried the color my designer recommended, which was a light gray – a color match of the Sherwin Williams Quick Silver. I applied it in the foyer to test it out. The next day I decided I did not like it. I expected it to be a light gray, but It had a hint of blue in it, which I did not want, Sorry, I didn’t take a picture of it. I really should have. Anyway, I considered making the walls the same color as the ceiling, but wanted some contrast, if only slight. So I opted for Behr’s White color. Not so white as Ultra White, but still white. I want the house to be bright. Here is a shot of the foyer so you can see the difference. It’s subtle, but present.

I really like this color for the walls. It just feels right.

In the kitchen I started with the ceiling (as one should). Since it is a tongue and groove ceiling, I used a brush to paint the entire ceiling. I wanted to make sure the paint was applied to all nooks and crannies. Consequently, this took a long time to apply and was not fun. I applied two coats, as usual. However, after the second coat I was not pleased with the results. You could see a lot of “roping” (i.e., brush strokes). I thought the paint would level out, but it didn’t. Here’s what I was left with after all that work.

This is all well and good if you’re going for the hand painted look, but I wanted a more polished look. So I decided to applied a third coat, but this time using a roller. Having used the brush to ensure all the seems were properly painted, all I really needed to do was smooth out the flat areas, so I figured a roller would do the trick. It did! And here’s the result.

That’s what I was looking for, and I was very pleased with the result. Note that I will add crown molding between the ceiling and walls, but only after the kitchen cabinets are in. They will dictate where the crown ends, so the crown molding must wait. Because I need the cabinets to be in before installing the crown, it also means the floors will be in (the cabinets will sit on top of the wood flooring), so when I come to painting the crown, drop cloths will be needed to protect them. Something I don’t have to worry about at this stage. It’s nice to be able to paint without concern about dripping paint on the floor.

Here are a couple more views of the kitchen where both the walls and ceiling are painted.

Not that it is noticeable in the pics above, but I did not paint the walls where the cabinets will go (from where the vent is hanging down and to the left of it), for obvious reasons. They were primed, but that’s all. It gives you an idea of how close the wall color I picked was to the color of the primer. There is a difference, but it is small.

Also notice how, other than the refrigerator, I had to empty the kitchen in order to paint. That was not such a big deal because of the mobile bases I added at the beginning of the year (see the post from January). So I’m glad I took the time to do that. After the painting was done in the kitchen, I moved everything back in, freeing up space in the great room for the contents of the dining room, which was the next area to be painted. The dining room was where I stored all the kitchen cabinets. You can see them in the image above. They were moved one at a time into the great room. No mobile bases for them, so that was a bit of a chore.

Here are some shots of the dining room fully painted.

In the last image above, you can see where I located the kitchen cabinets in the great room. You can also see in two of the images above that I have not yet installed a light fixture in the dining room. The wire hanging down is hooked up to the switch on the wall, so it’s ready to go, but having that light fixture in place is not really required before I move into the house. I haven’t decided on a fixture yet, so I’m inclined to put that off until I’ve moved in. By waiting until the piano is in position I’ll be able to raise the lid and see exactly how much room I have between it and the ceiling, which could impact my choice of fixture. However, with the piano in place directly under the fixture location, it will be in the way, making installation a bit tricky. Fortunately, I don’t have to make this call until closer to move-in time.

Below are some images of the other areas I painted.

Within the guest hallway you can see that the plenum on the ceiling does not have a grate yet. That is because I reduced the size of that opening to accommodate the full width of a tongue and groove board. Therefore, the original grate no longer fits. If I’m unable to find a grate to fit the space, I’ll make one myself. Either way, this is not a priority for me at the moment.

As with the dining room, I’m in no hurry to install wall sconces, so the guest hallway and foyer will remain without them until I feel inclined. I can move in without these in place, so they remain a low priority.

The above image of the great room is obscured by the contents I’ve left in the middle of the room. I will probably leave the cabinets and other bits and pieces right where they are until it’s time to put down the flooring. I thought I might move the cabinets back into the dining room, but I see no benefit to that at the moment. I’ll move them only when necessary.

From this view, you can see how much stuff occupies the great room. The mobile wood storage cart on the left will be moved into the garage, as will the various tools, but not until I no longer need them to be handy.

I installed the switches, electrical outlets, and the face plates for the Ethernet boxes in the various rooms only after all the painting was done in these areas. While installing the switches in the kitchen, I ran into some issues. The kitchen has two 3-gang boxes to control the ceiling lights, under counter lights, and kick plate lights. Each 3-gang box has three 3-way switches, so these lights can be turned on and off from either location. You can see them in the image of the kitchen (Northern View) above. Here it is again for your convenience.

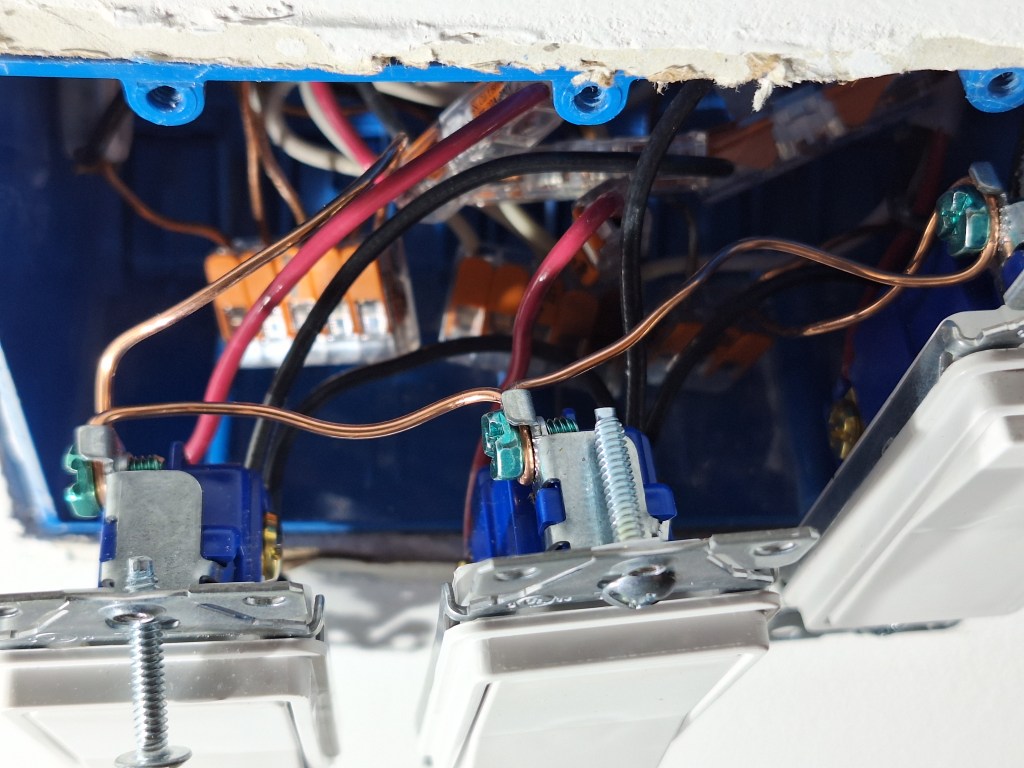

On the wall near the laundry room you can see that there are three switches installed (with no face plate). On the wall near the great room you can see the 3-gang box with no switches installed; just wires exposed. When I started hooking up the switches in these boxes, I began with the box near the laundry room. I pulled out the existing switches in the 3-gang box (what you can see above) and discovered that the wires within that box were very short. Also, the box itself was not very well supported. So I had some work to do to put in new switches and it was going to be tricky getting the switches to align. But what bothered me most was why it was in this condition.

That wall had been completely pulled apart and a new 3-gang box installed, all done by me. Not only that, but the three switches were also installed. So the question I had for myself was, why did I do that? Those three switches weren’t controlling anything, so why did I install them? They would only get in the way (as they did) when it came time to putting up and finishing the drywall. Fortunately I have a BLOG, so I went back and looked for the post when I did that work and found it in the post of March 2021. During that time I had not done any drywall, so I didn’t understand the benefit to keeping the boxes free of switches and well aligned and secured. I also was trying to figure out the wiring for these switches, so I wanted to install them and verify they worked, thinking it wouldn’t be long before I’d be installing the kitchen cabinets. Of course, after all that was done, and many moons later, I reconfigured the kitchen, resulting in my having to undo the electrical work on the wall by the great room. However, during that time, I did not touch the electrical on the wall by the laundry room and just forgot about the state it was in.

In that time, I’d done a lot of drywall work and therefore gained an understanding of the importance of securing the electrical boxes properly and keeping the wiring out of the way. So when I finally turned my attention to the wiring of these two boxes in the kitchen, I was most surprised by how short the wires were inside the box by the laundry room. Installing new switches was going to be very tricky because I had almost no length to work with. What I think happened was that I was trying to minimize the length of wire to reduce the amount of crowding within the box. With three switches in a single box, plus the wires heading out to the lights, it can get pretty congested. That was a mistake. So in order to fix it, I had to splice in some extra wire to give me the length I needed to install new switches without having to resort to wiring gymnastics.

Although it is not clear in the image above, you can see plastic connectors with orange tabs. These are call WAGO connectors. They come in different sizes, allowing one to connect multiple wires together easily. They also have a nice “inline” connector, shown below.

This connector makes it easy to extend a wire with minimal space impact. If you look closely in the image of the 3-gang box above, I have used several of these in the back of the box to splice in new wires to give me the length I needed to add the new switches with far less difficulty.

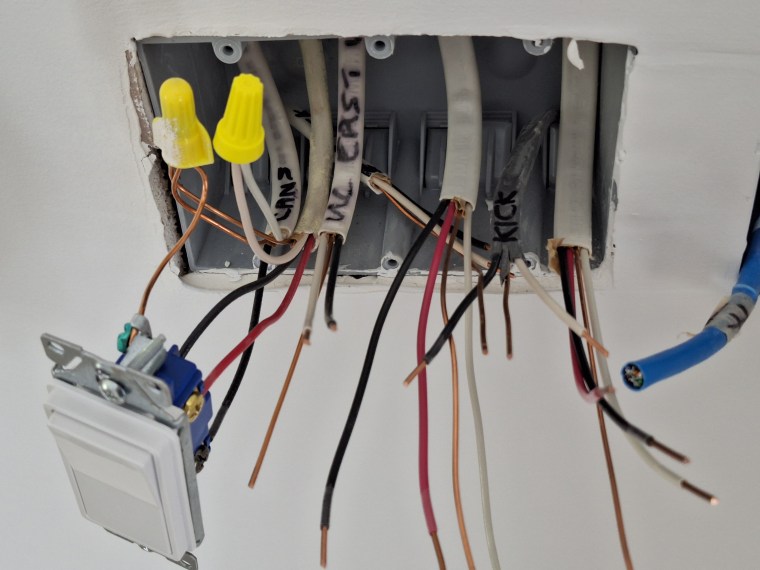

Here is an image of the other 3-gang box. The one on the wall near the great room.

This is how it’s suppose to be. Plenty of wire for me to work with. In this image you see that I have hooked up the 3-way switch for the overhead lights to make sure this switch works in concert with the one on the other wall to control the overhead lights. I then did the same with the other switches. Note that I swapped out the yellow wire nuts you see above with WAGO connectors when putting the other switches in. It made it much easier.

What all this shows, is that nothing beats experience; something I am gaining with every new task. My next task is certainly new; tiling the shower wall in the master bathroom. With the painting of the main areas of the house complete, I’ll be returning to the master bathroom to pick up from where I left off. That will be the subject of the next post.