Kitchen – April 2023

This post was written concurrently with the one for the master bathroom, so you should start with that one (Master Bathroom – April 2023) to keep the time line straight.

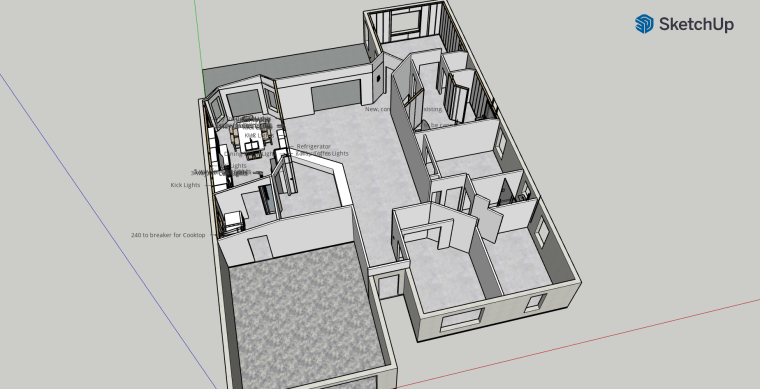

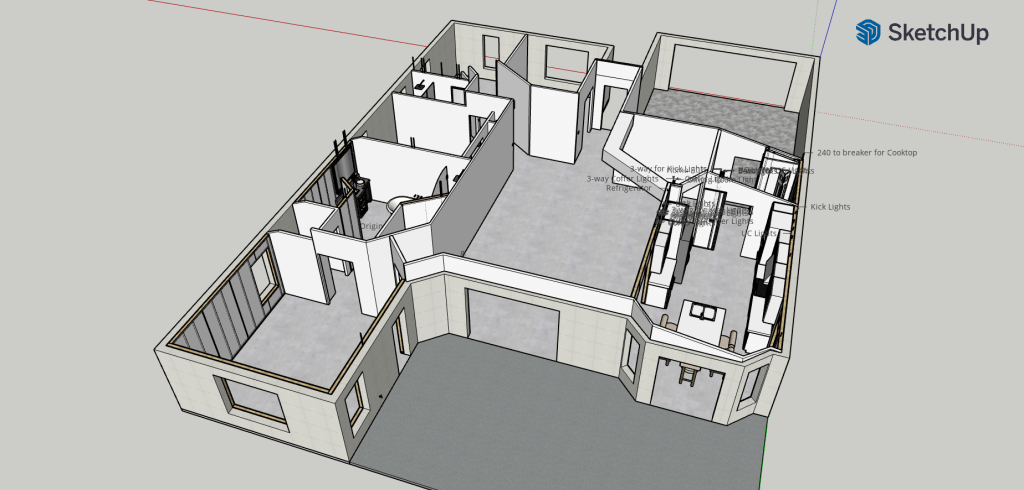

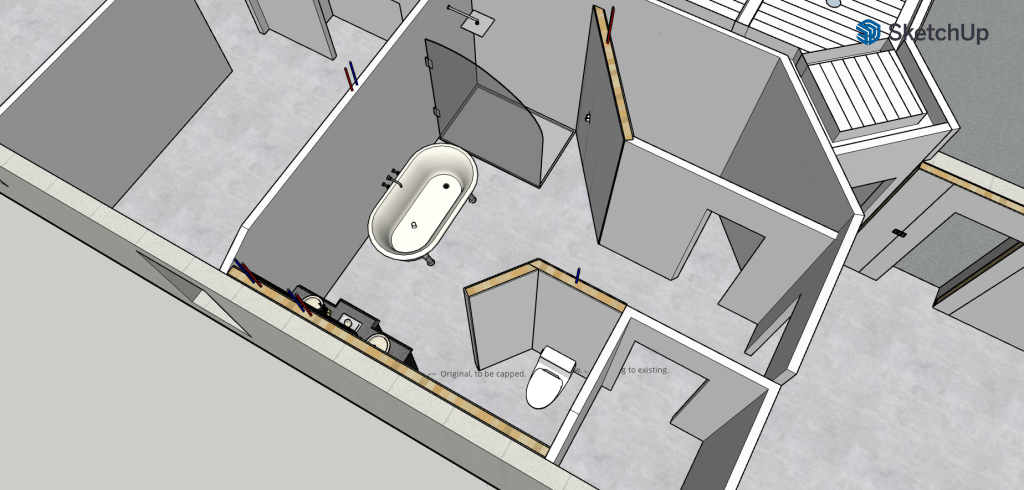

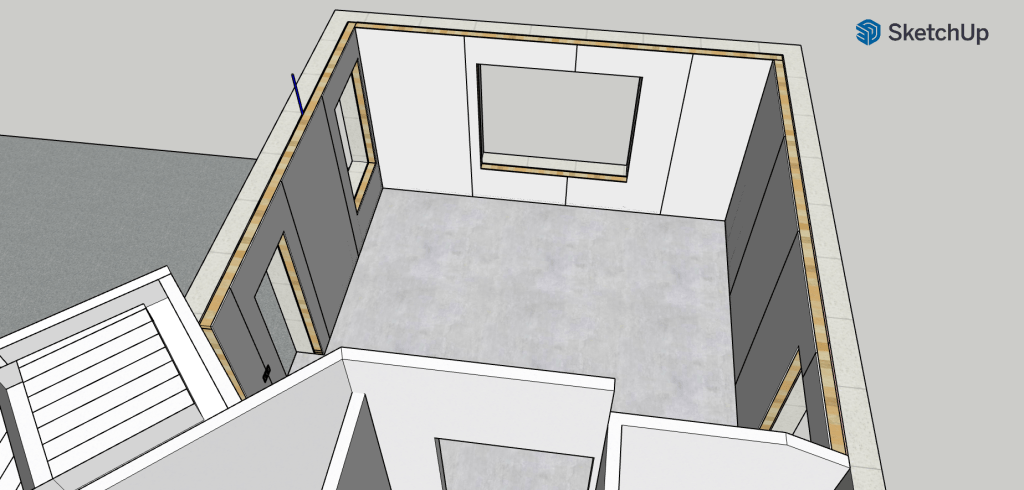

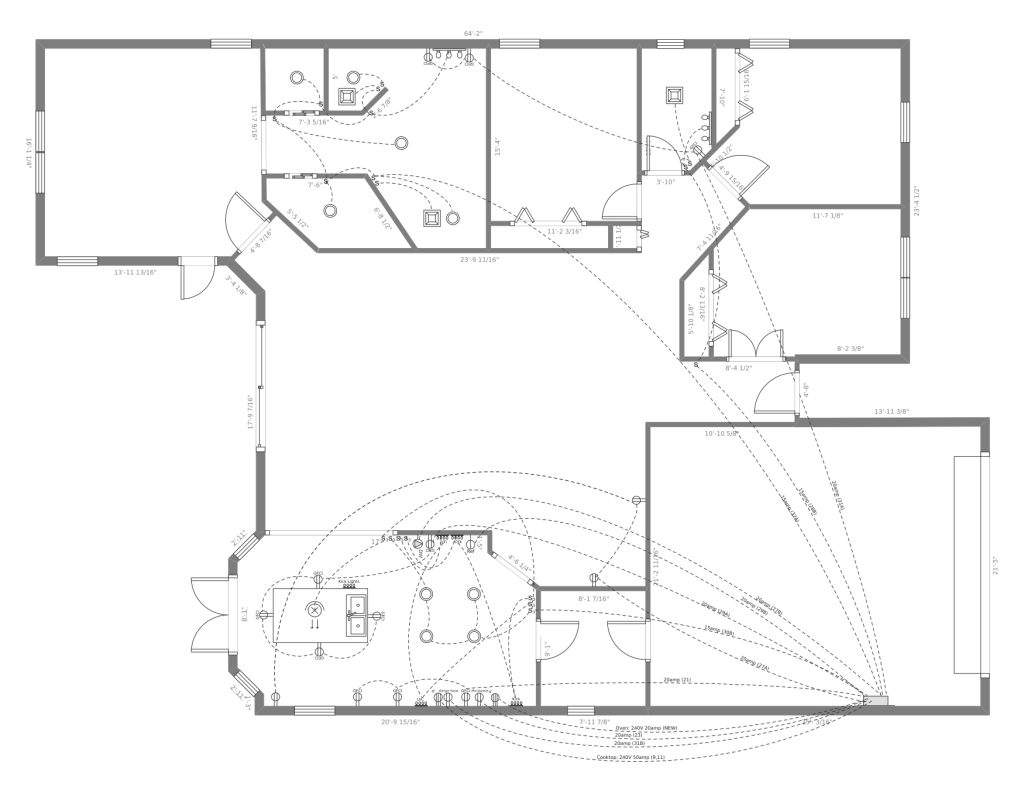

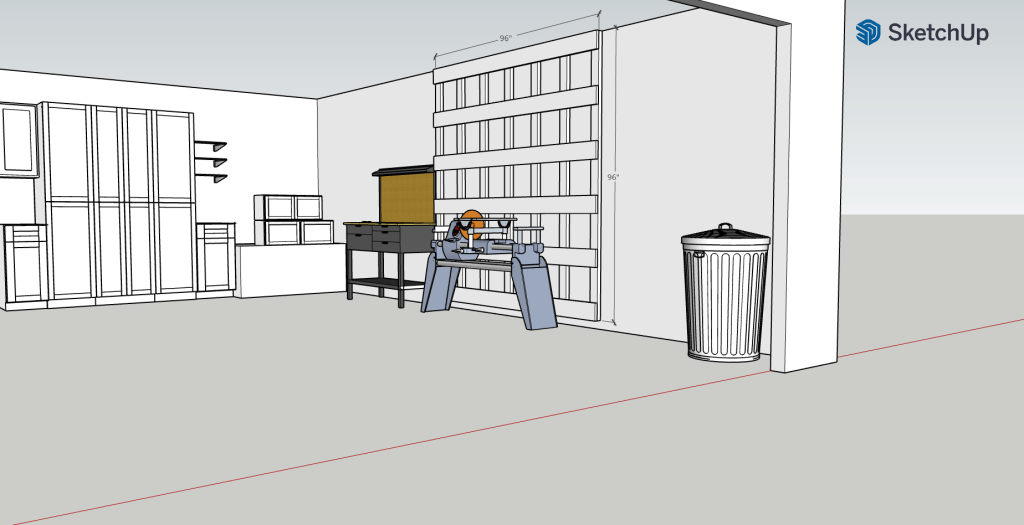

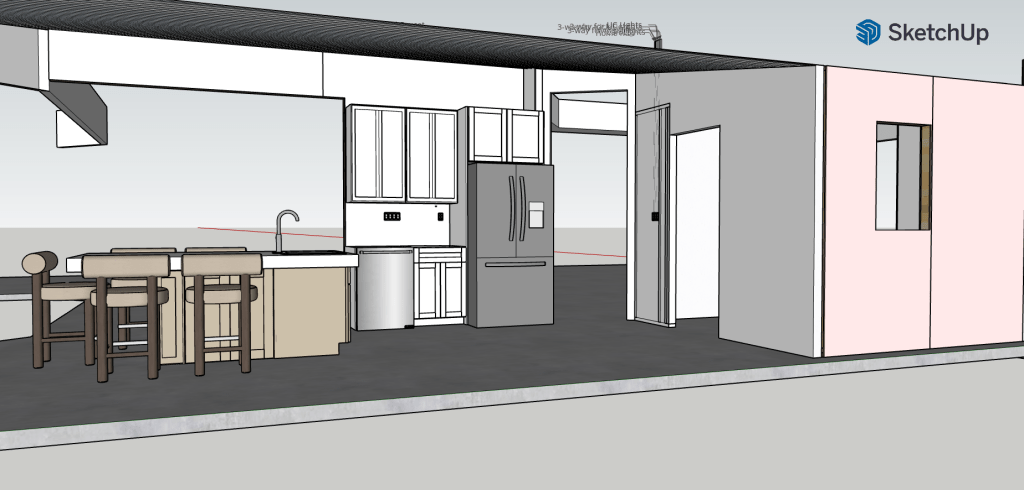

Since I had to wait for the concrete in the master bathroom to cure (I wanted to give it a week to be certain it was safe to drill into it), I turned my attention to the kitchen. While I was doing the concrete work in the master bathroom, I received word that the revisions to my permit, that I submitted a couple of weeks prior, were approved. So now it is time to reveal the changes to the kitchen. I start by showing images of the original plan.

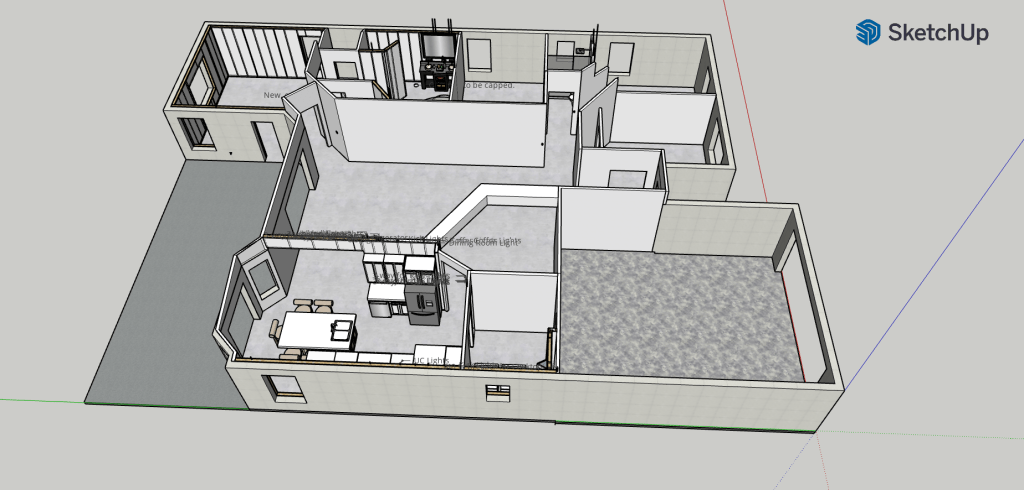

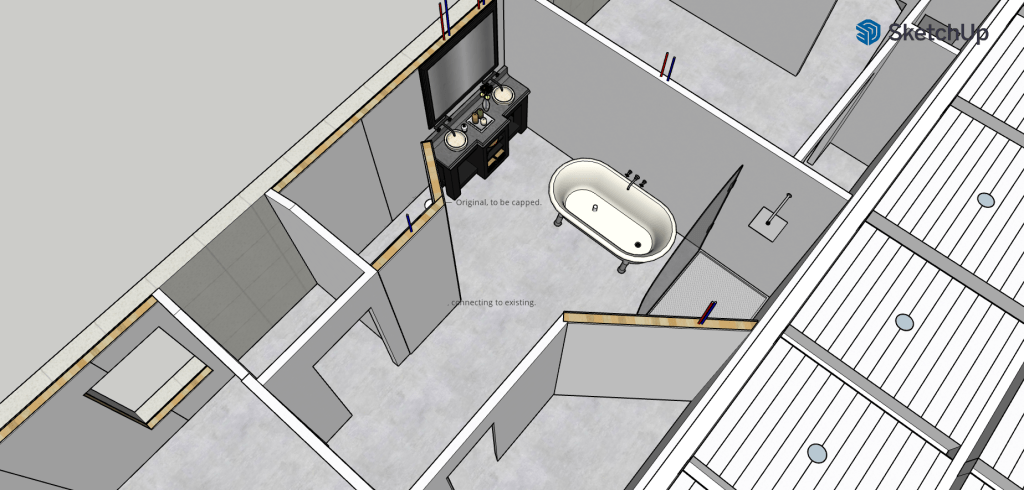

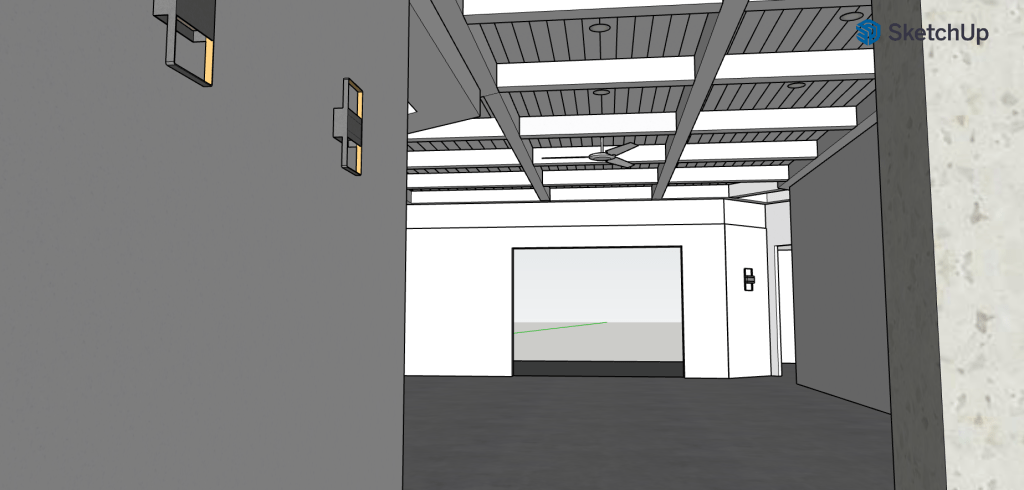

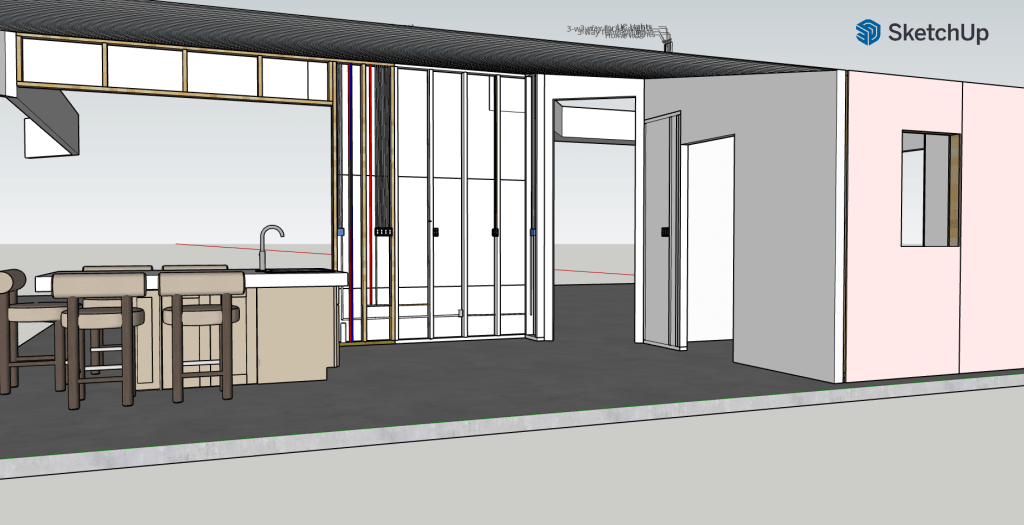

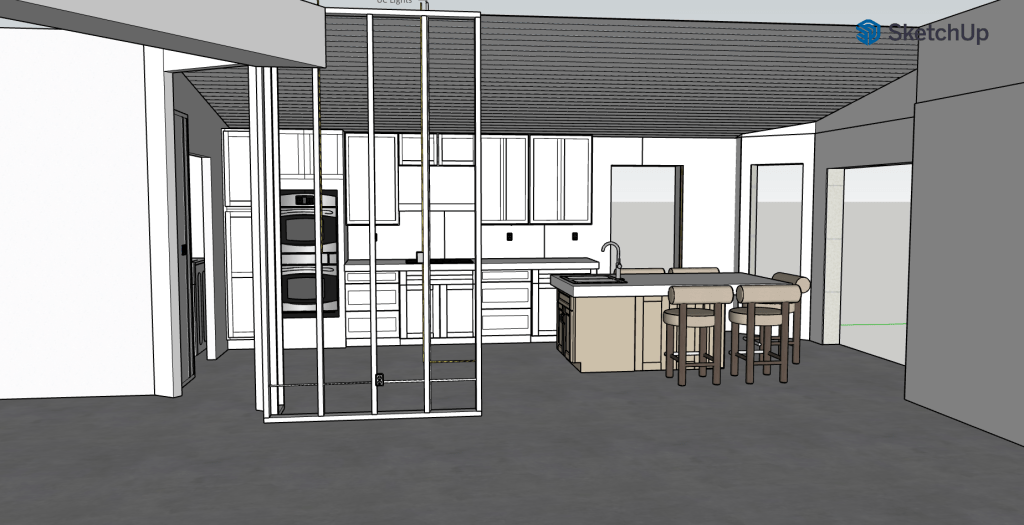

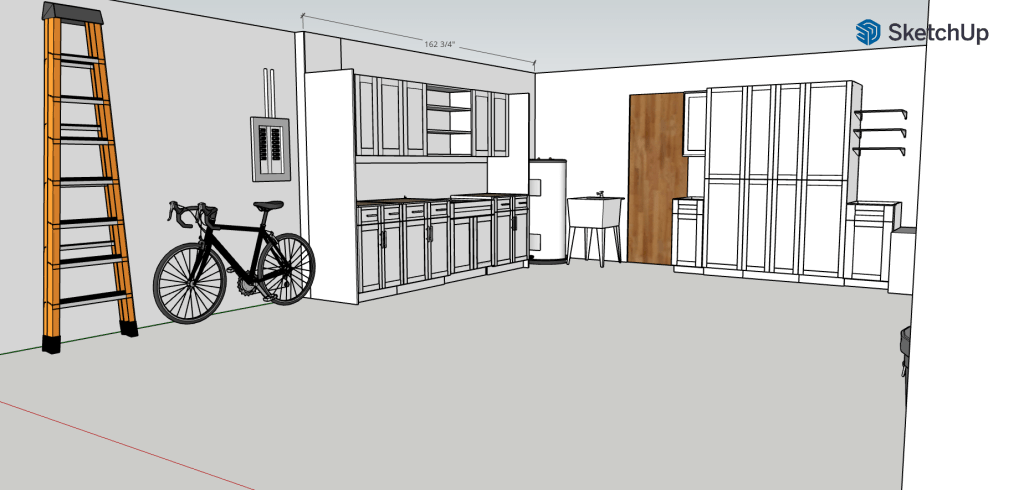

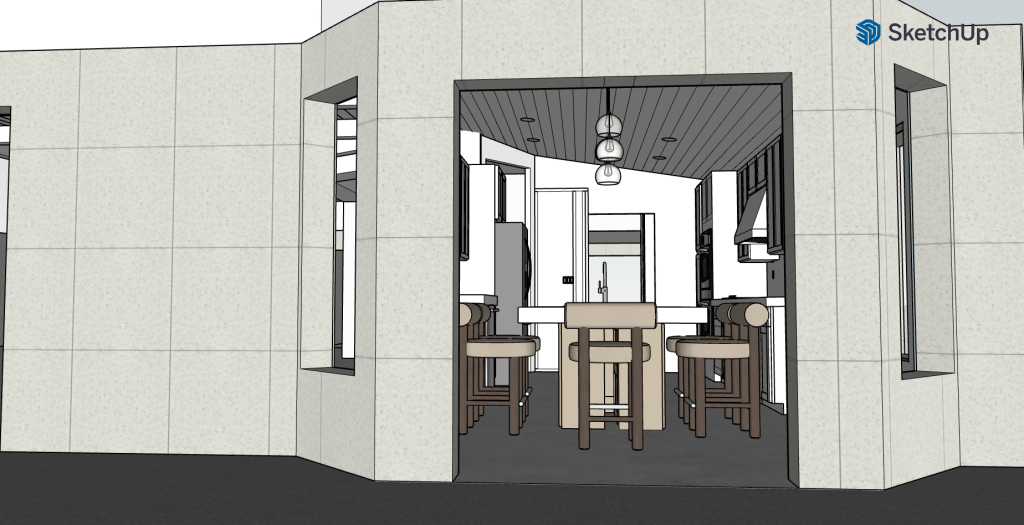

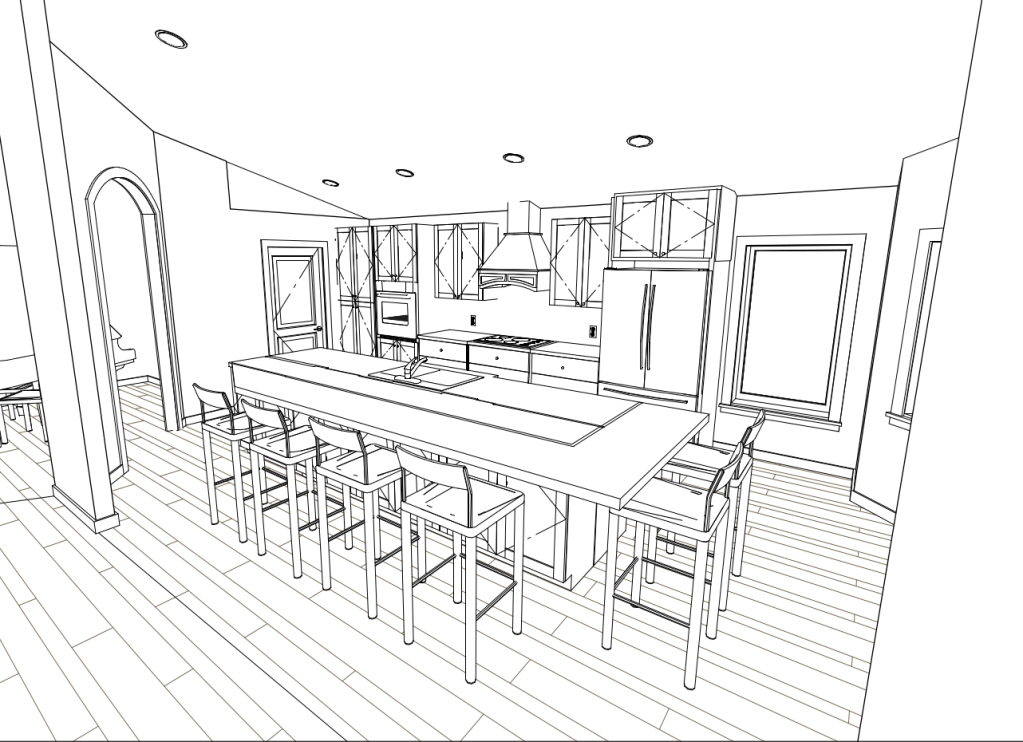

And here is what the new plan looks like.

This rendering is not exact. It just gives you a sense of what is coming. The entry to the dining room will not have an arch, and who knows what vent hood will be selected. What is worth noting is that I will be removing a significant part of the wall that divides the kitchen from the great room. The designer, Jennifer, convinced me that my original plan provided very little prep space. The part I really liked in my original plan was that I would be looking out over the beautiful view I have as I stood at the sink. But she was right, and this makes more sense. The refrigerator will move to the opposite wall from where it was and the dishwasher will be housed in the island. To prepare for this, I had a lot of electrical and plumbing lines to relocate. I’ll also have to do some more cutting into the slab to route the water and electrical lines, and there will also be some modifications made to the drains (so more concrete to pour in my future – yay!). But that will be covered in another post.

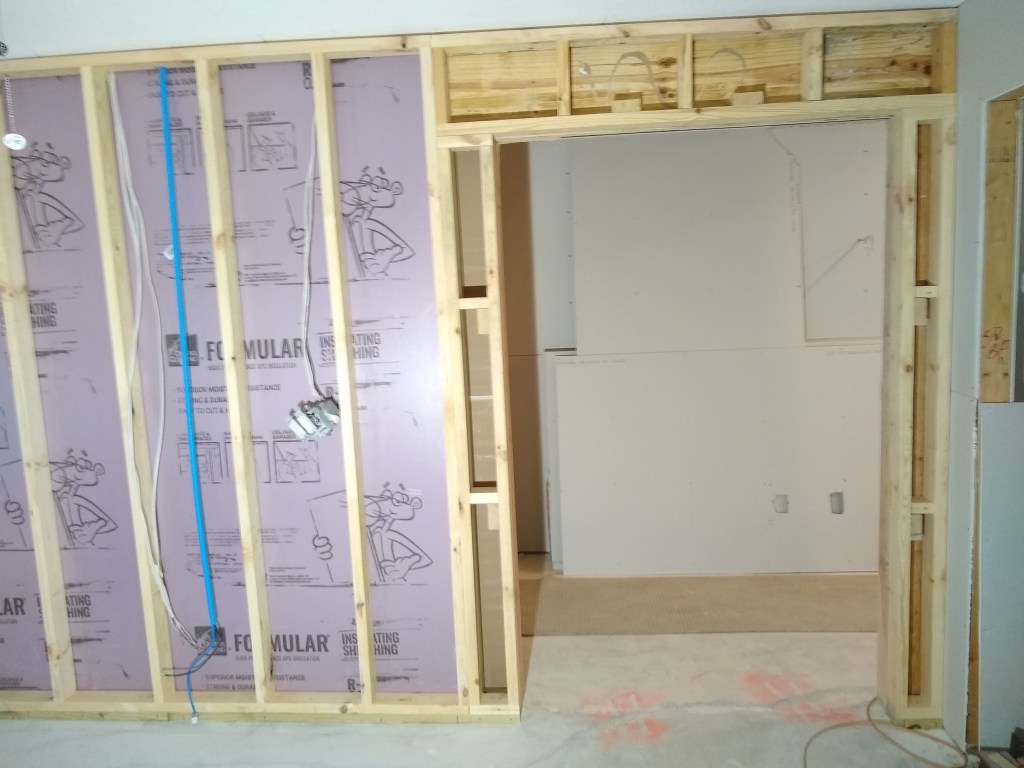

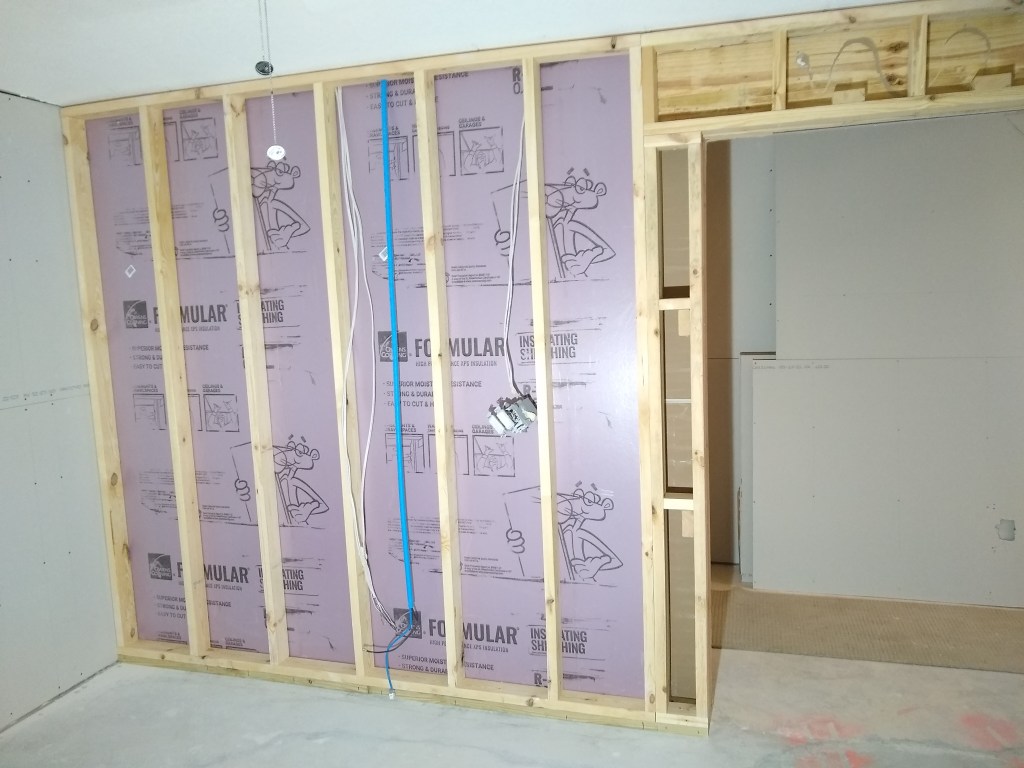

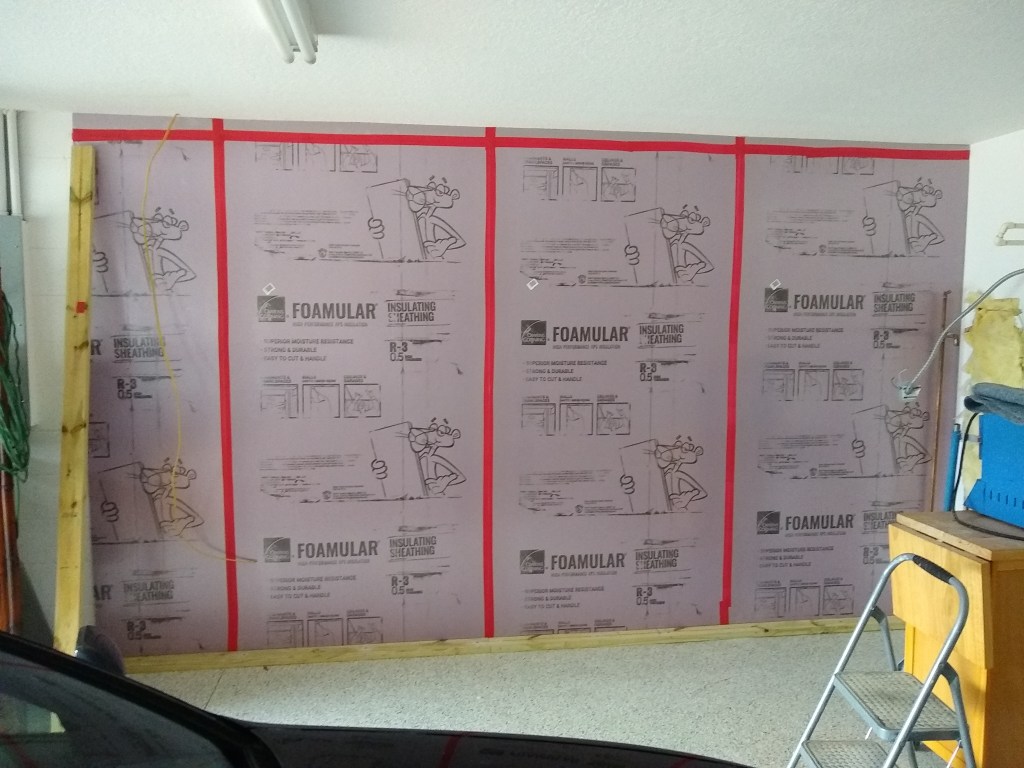

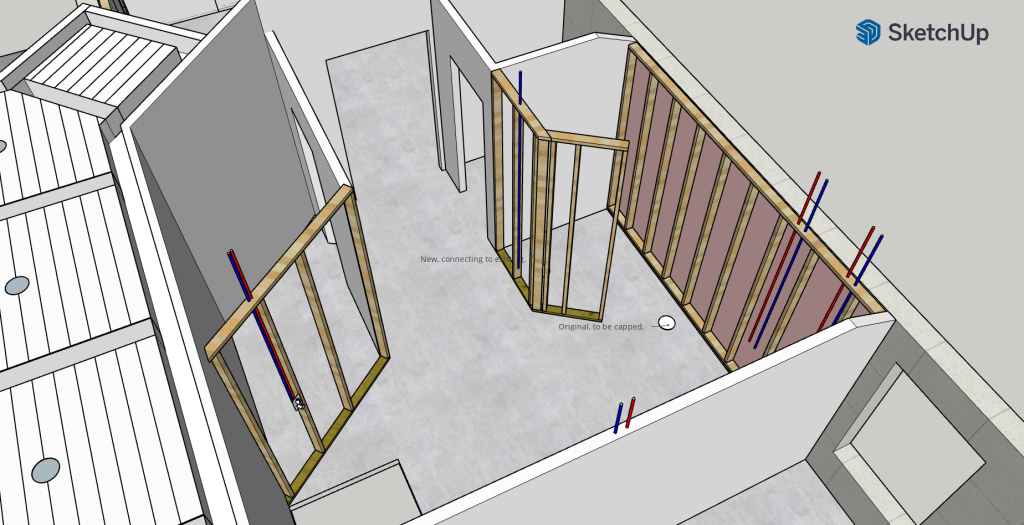

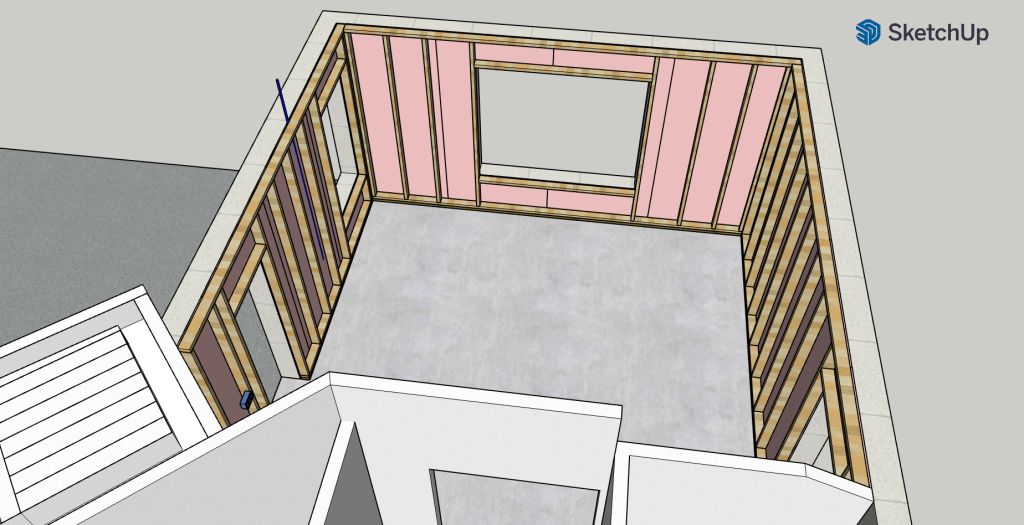

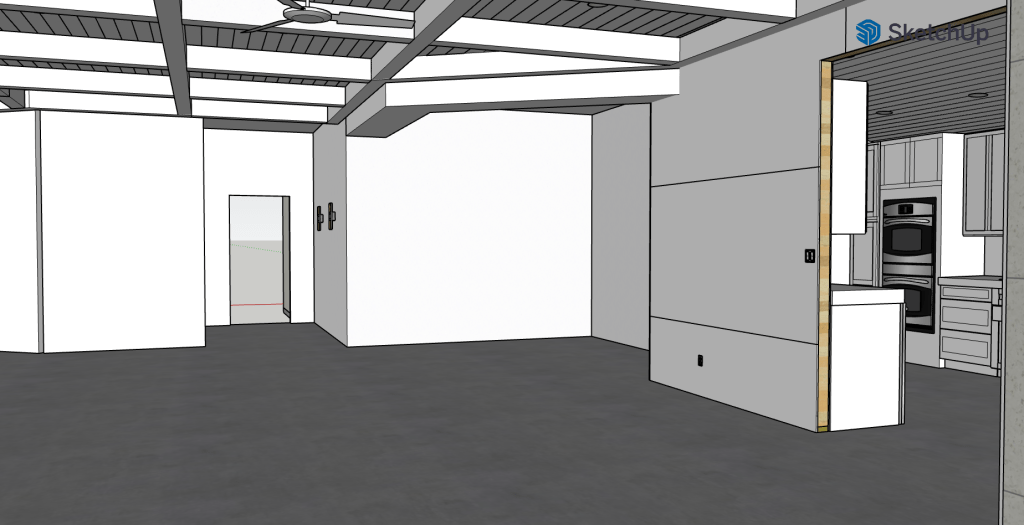

I began by removing most of the existing wall that divides the kitchen from the great room. Here is the before image.

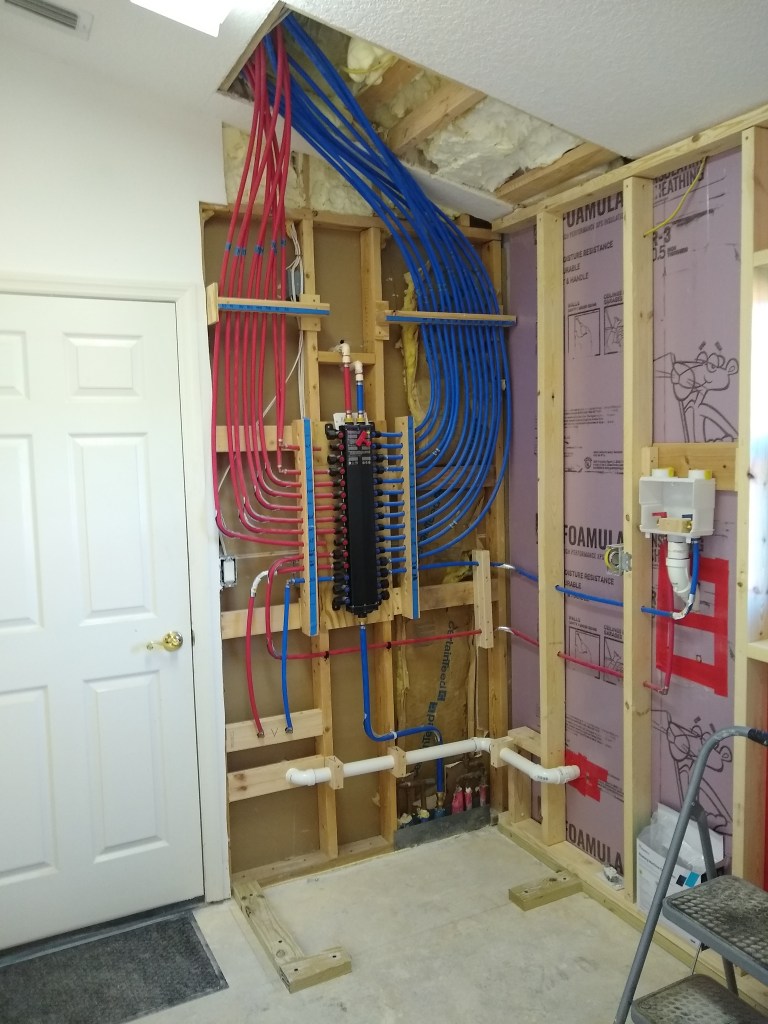

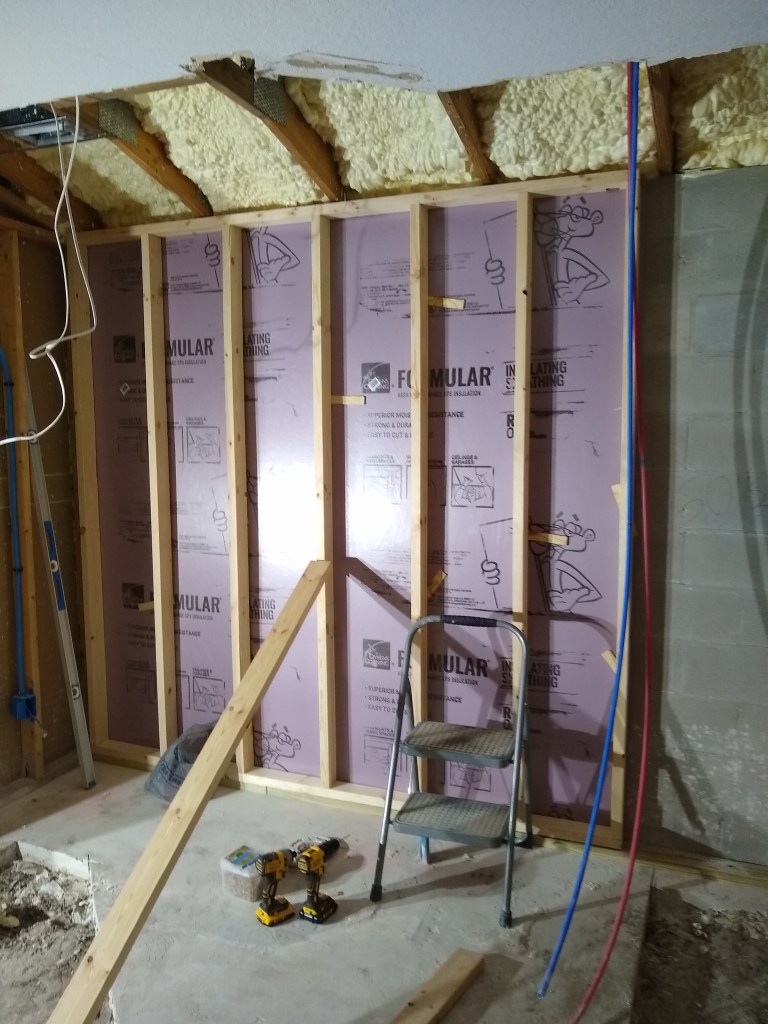

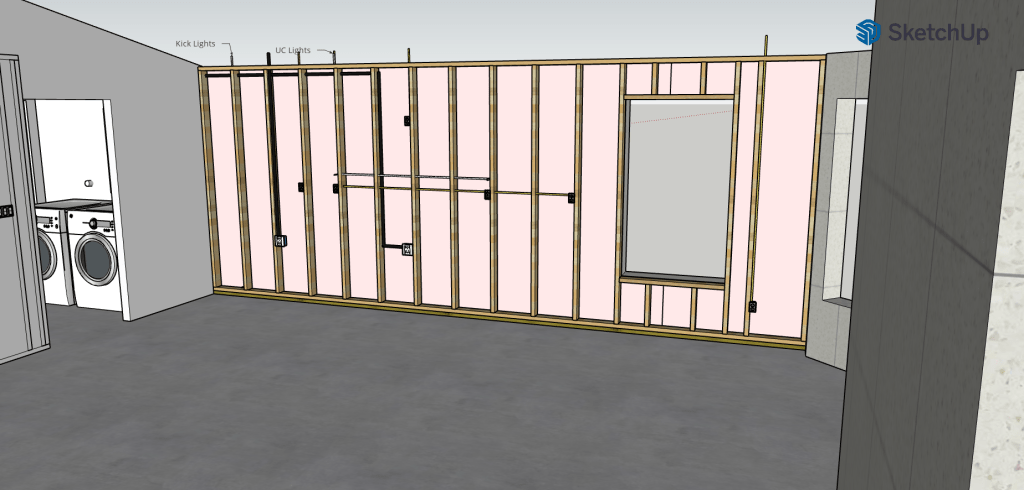

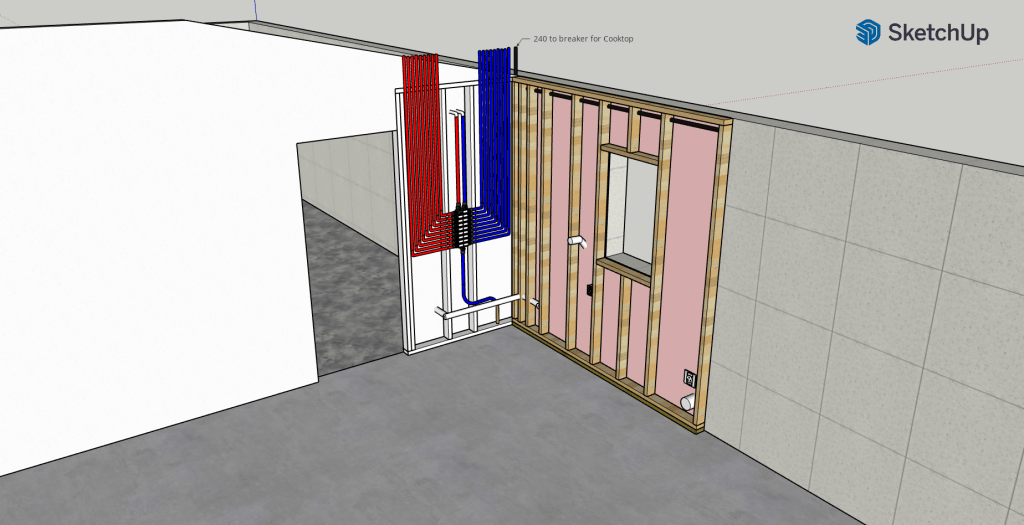

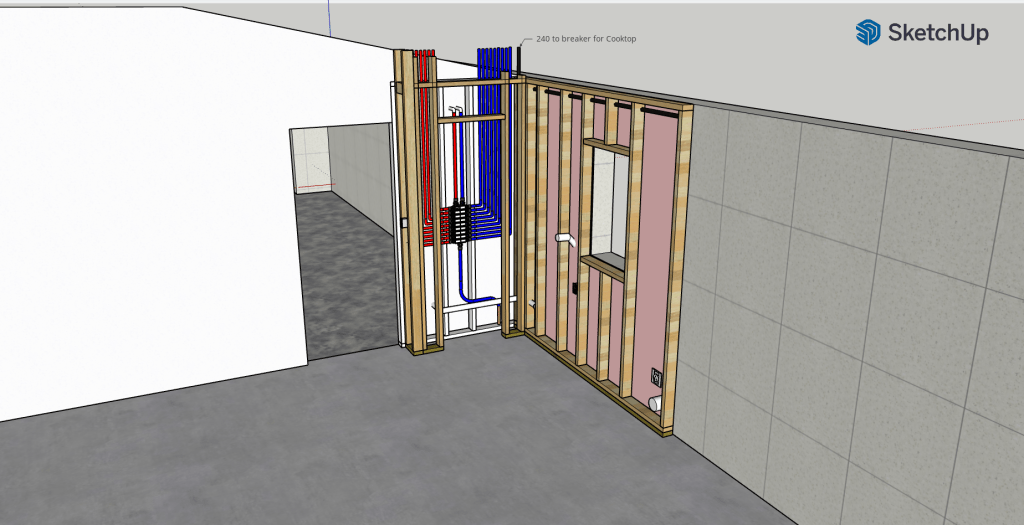

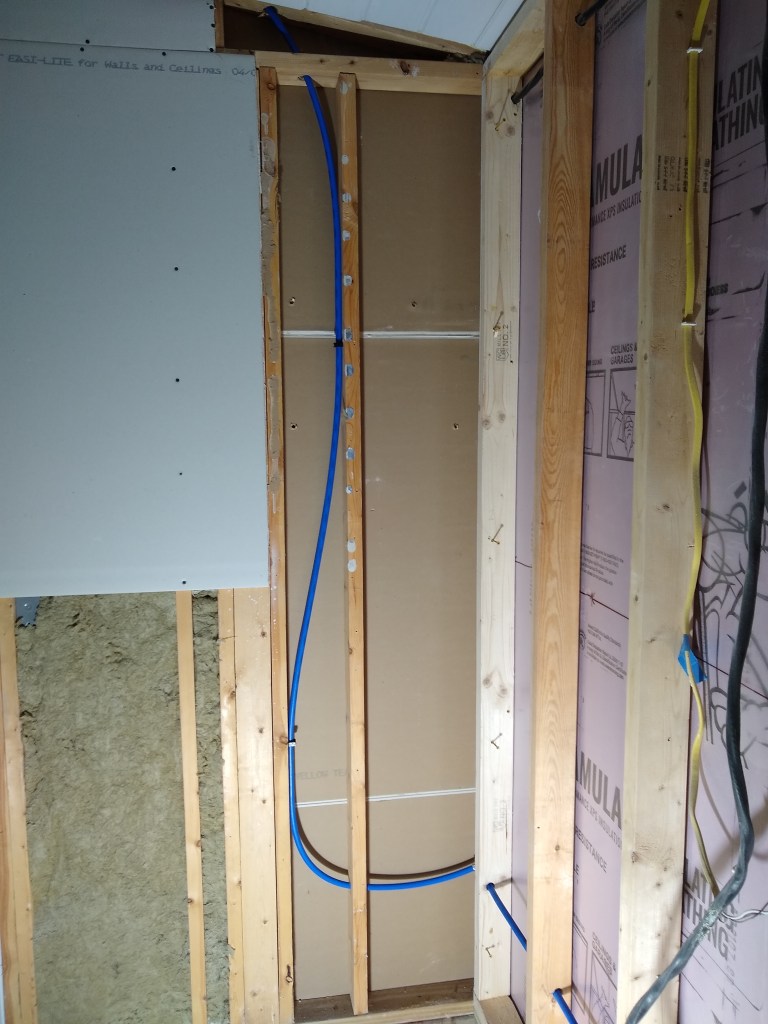

Notice the electrical and water lines that had to be relocated. In the image below I have moved the lines and removed most of the wall.

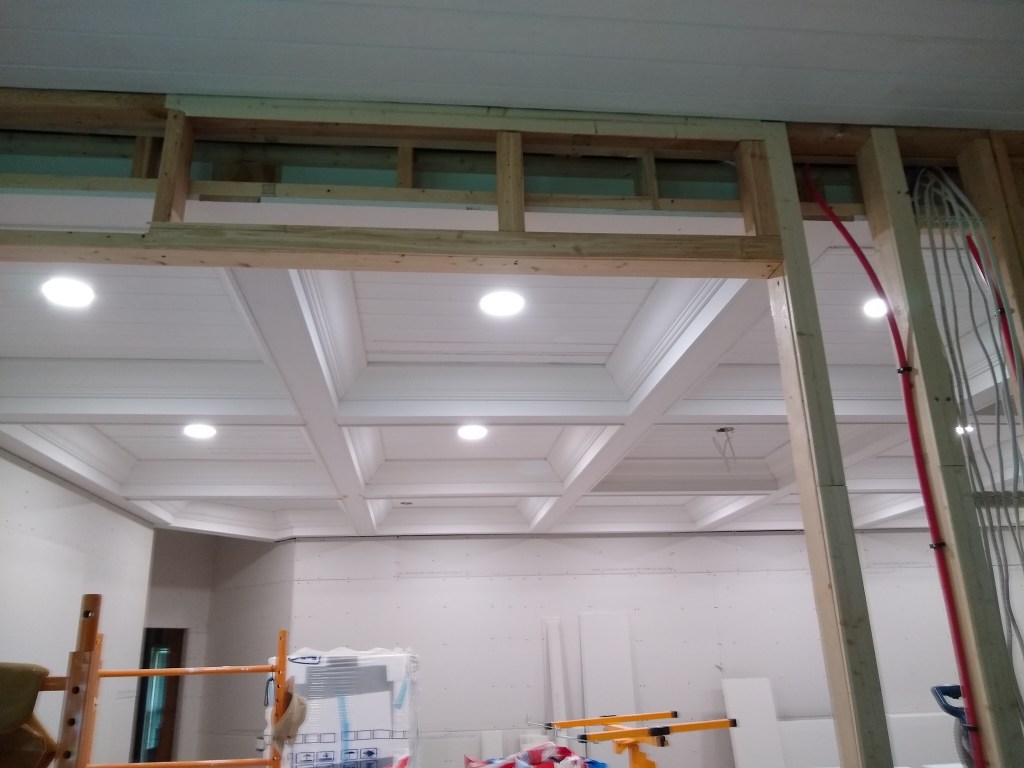

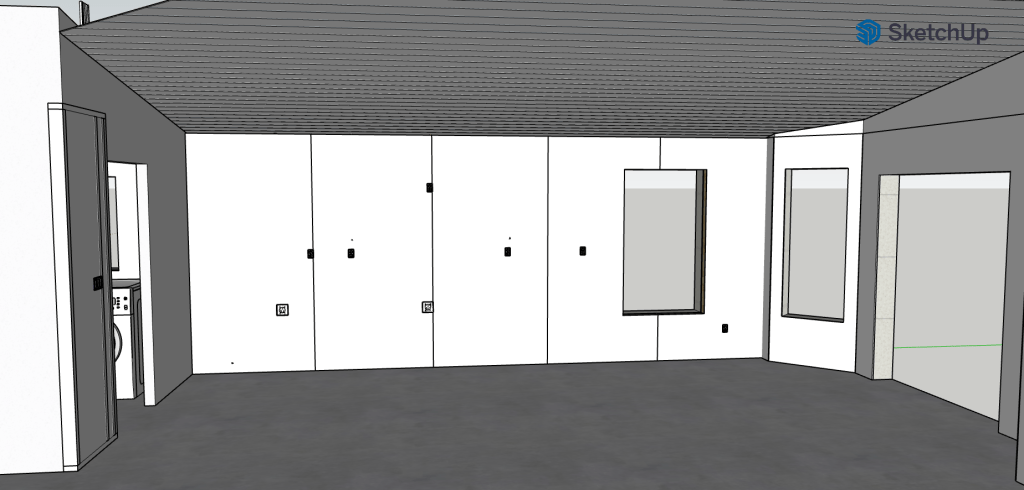

And here is the result. Note the new framing up top to connect to the existing part.

There is about 2 feet of the wall remaining, and that is there because we needed somewhere to put switches and water lines.

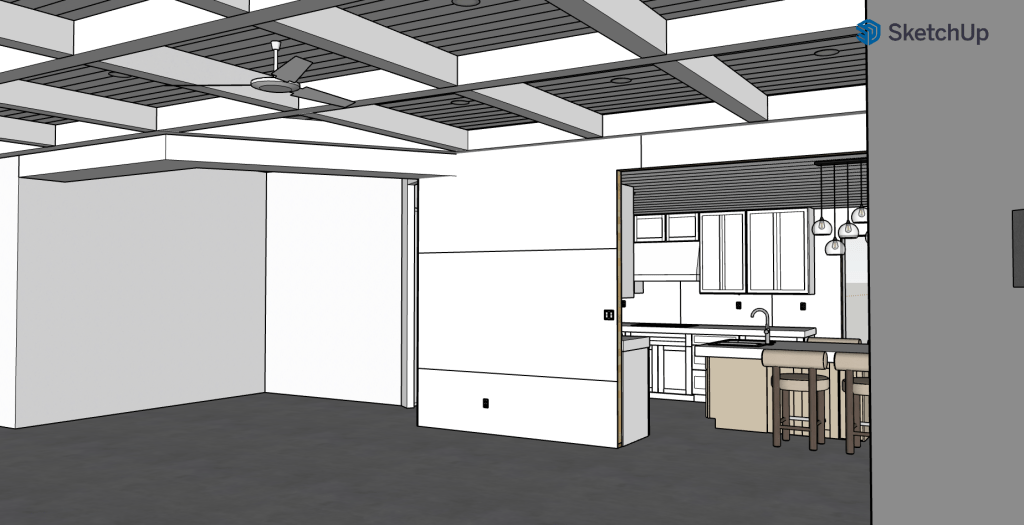

Here are some images of a mock-up of the kitchen island to give you a sense of how it sits in the space.

After doing this mock-up, it became apparent that something was a bit off with respect to the dimensions. It was too big, leaving little room to maneuver around it at the ends. I discovered that there were measurement issues and spoke to Jennifer about it. The upshot is that I will reduce the size of the cabinets at either end to open things up a bit. No big deal. But you can get a sense from the images above how the island will sit in the kitchen.

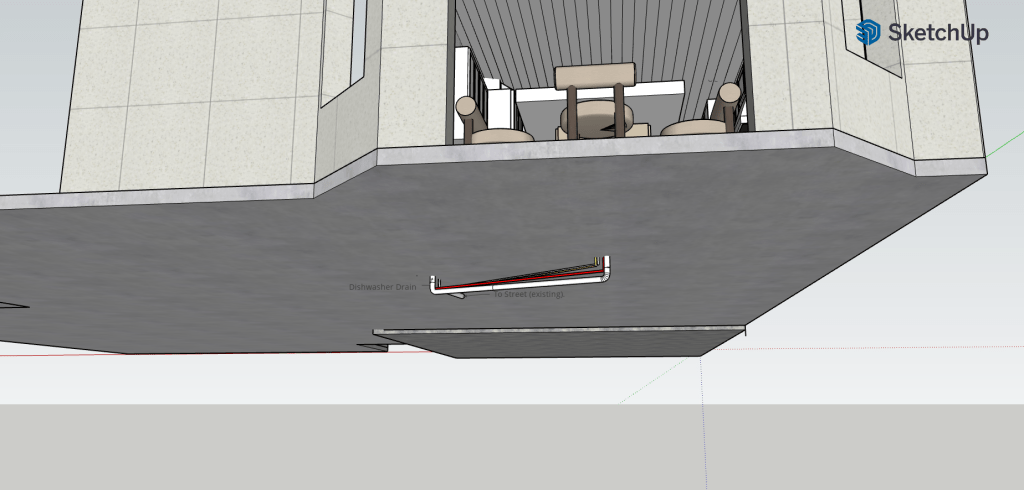

Although not planned that way, the existing trench is well positioned and will line up nicely with where the sink will go. I’ll just have to move the drain in by a couple of feet. However, to accommodate the supply lines, a new trench will have to be cut to connect from the small wall where the electrical and plumbing lines are to the existing trench. Before getting to that, though, I relocated the water line for the ice maker in the refrigerator.

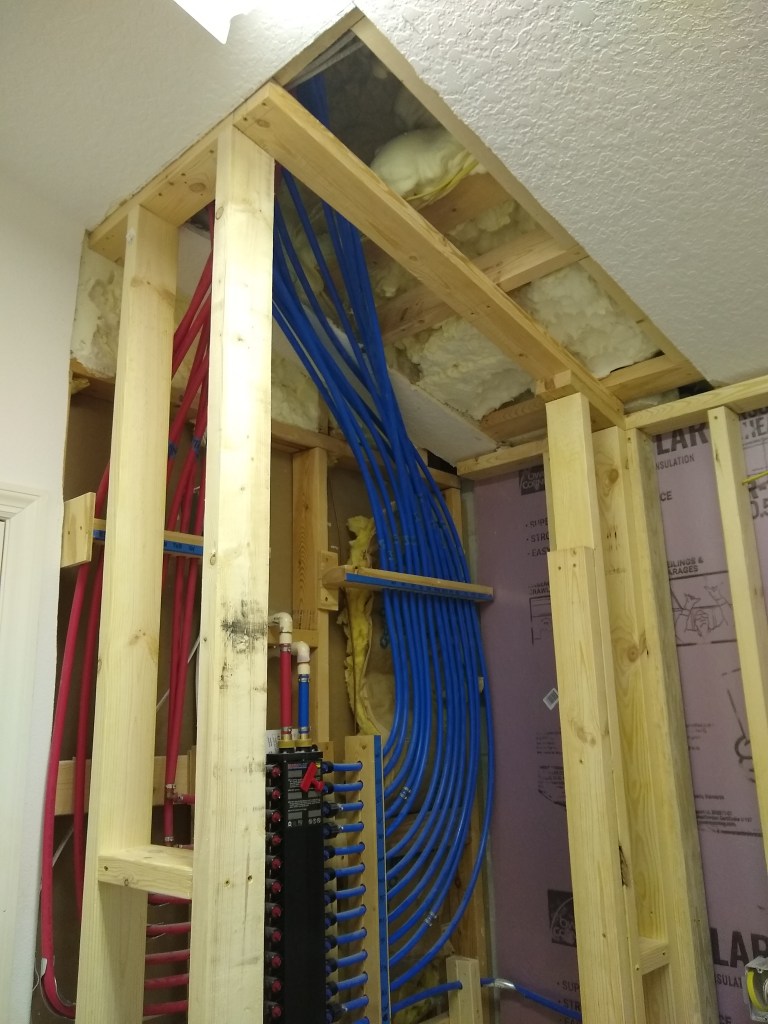

I moved the water line so that it enters the kitchen from the ceiling within the wall that separates the kitchen from the laundry room. I would have preferred to send the line most of the way above the ceiling and bring it down directly above the refrigerator, but with the spray foam insulation and the sloping ceiling, there was no way I could access that area. It was tough enough bringing the line down here. Very tight quarters. I was laid out flat on my stomach to reach the opening I drilled.

Once the line was pulled down I had to extend it almost the entire distance along the east wall of the kitchen, which was easy enough, just a lot of holes to drill.

This required a 90 degree connection; the only connection along the span, which isn’t bad. I had to remove the vertical 2×4 that was installed as a nailer so that I could get access. When I put the nailer back in place (you can see it in the pic above), I cut out a notch to make room for the connection.

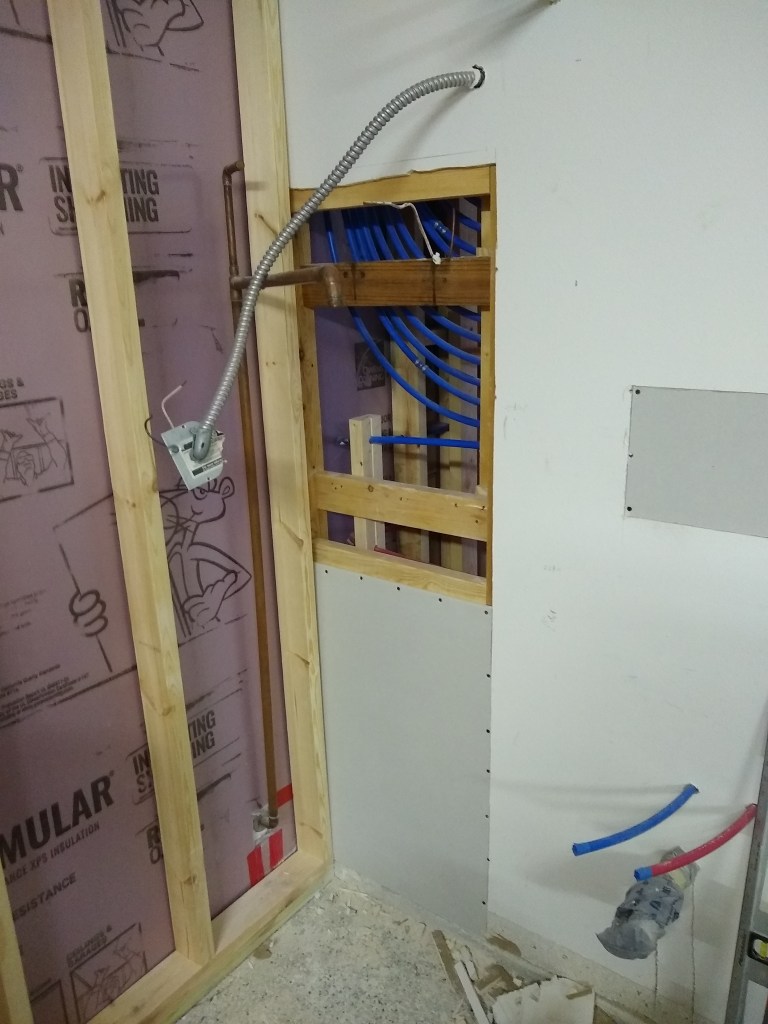

I had to do something similar with the electrical connection for the refrigerator. Like the water line, I couldn’t simply drop the wire down from the ceiling at it’s destination due to the spray foam insulation being in the way, so I routed it through the plumbing closet in the laundry room.

Since the length of wire from the original fridge location was not long enough to reach the new location, a junction box was needed to splice in a length of wire sufficient to finish the journey. The wire exiting the junction box followed the path of the cooktop wire (black) until the dividing wall, where I had to drill a separate hole because it was just too tight from that point on. Below you see it emerging from the laundry room into the kitchen.

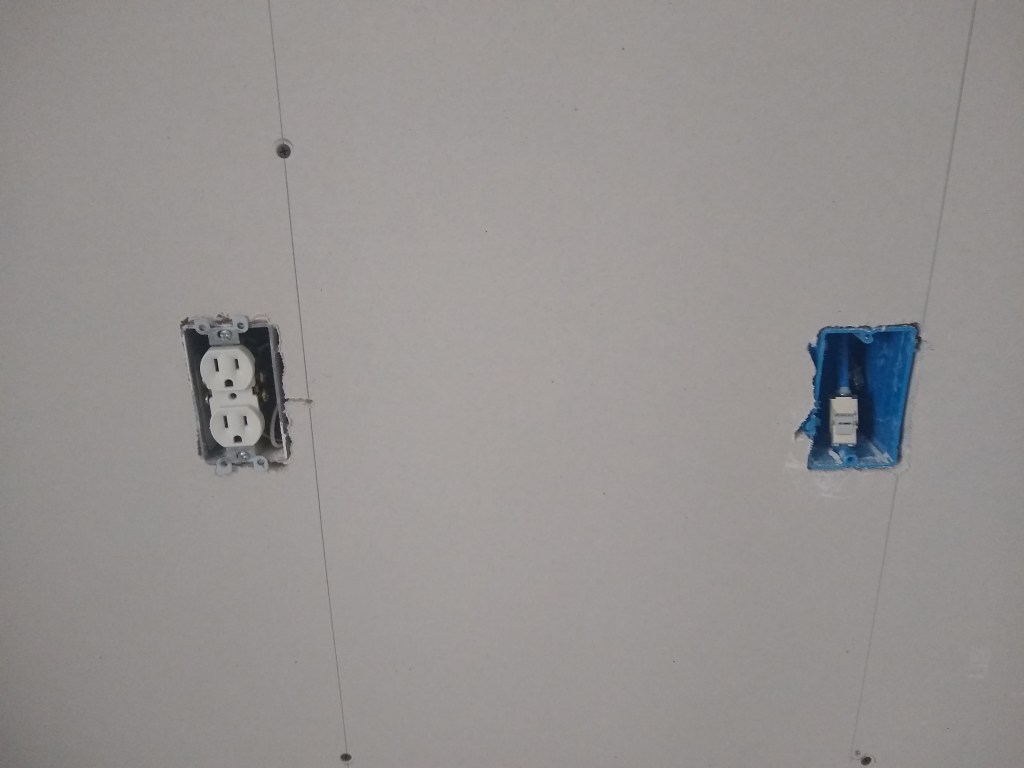

And finally to the fridge location, shown below beside the end of the blue water line. I had just enough wire to reach (I was trying to avoid having to buy more). It was too close, actually. I ended up installing the outlet box a bit higher than I normally would just to make sure I had enough to play with when it was time to install the receptacle. The location of the outlet is not critical because it will be hidden behind the fridge, so I chose to take advantage of that rather than make the final hookup more finicky than it needed to be.

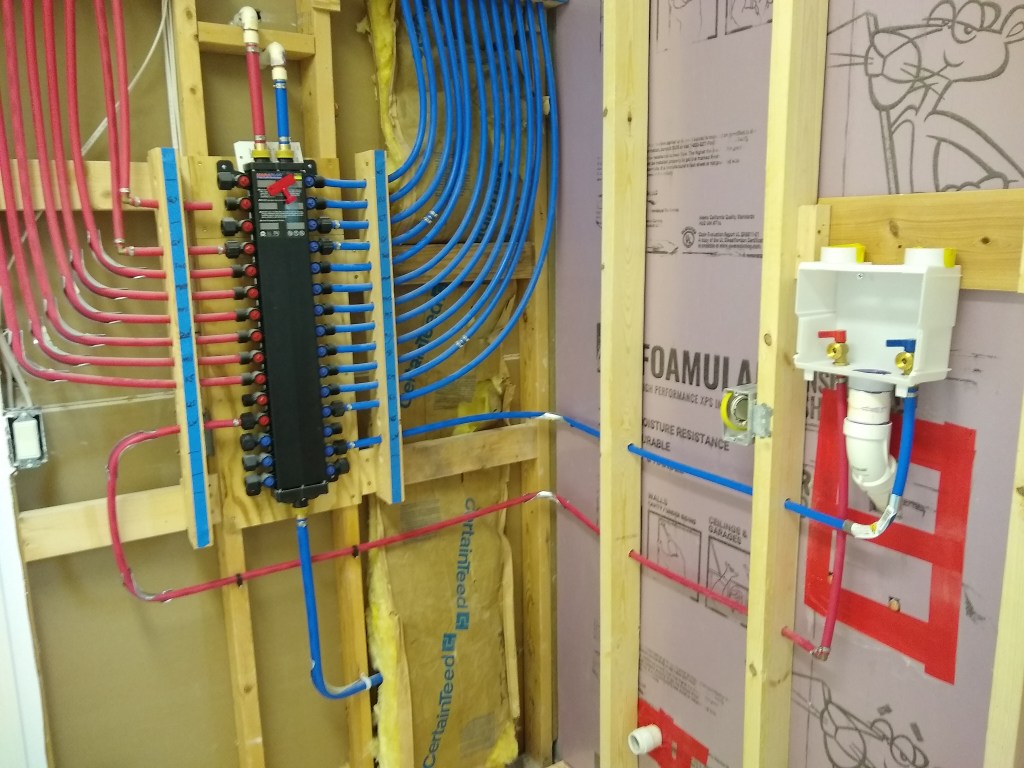

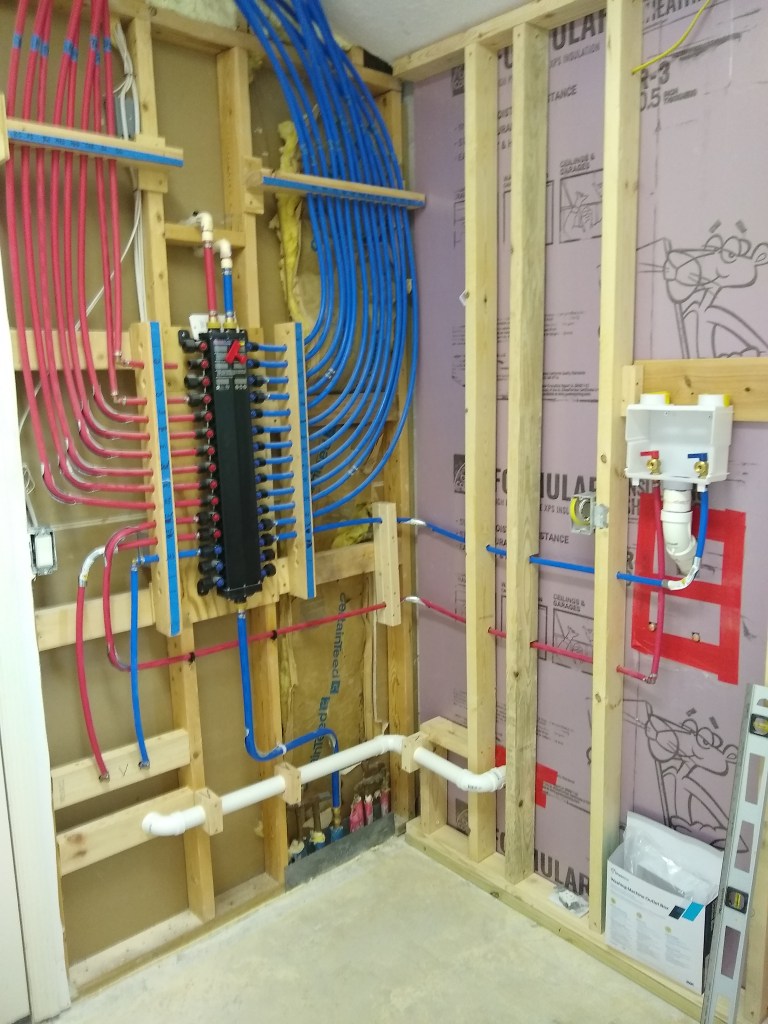

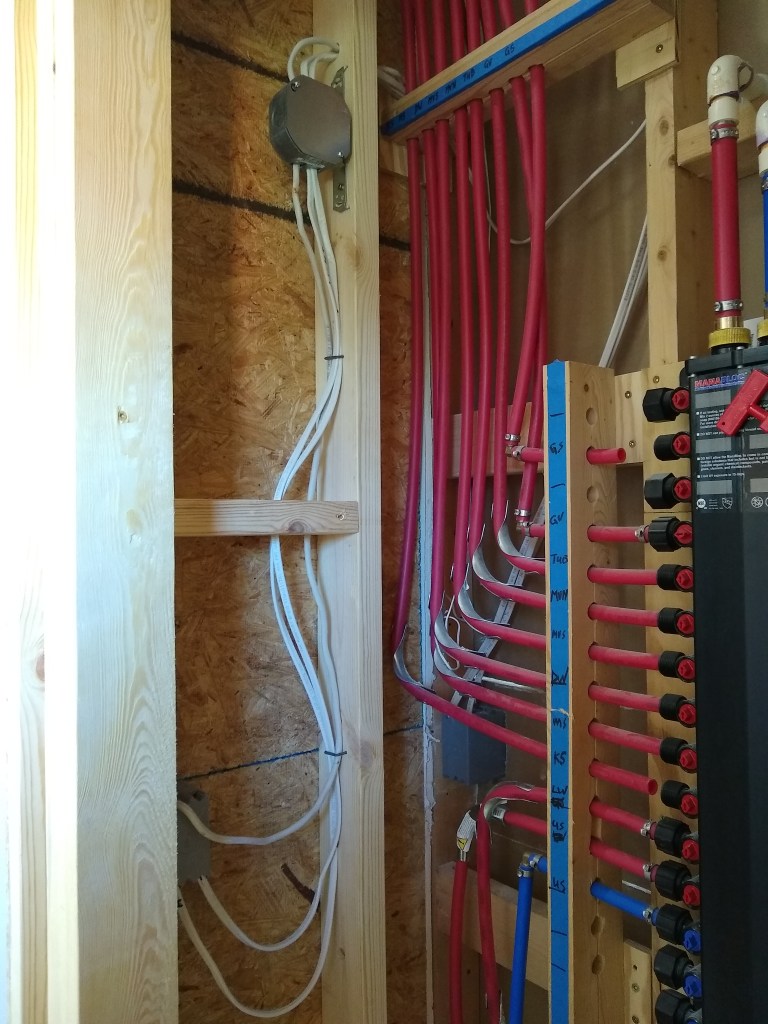

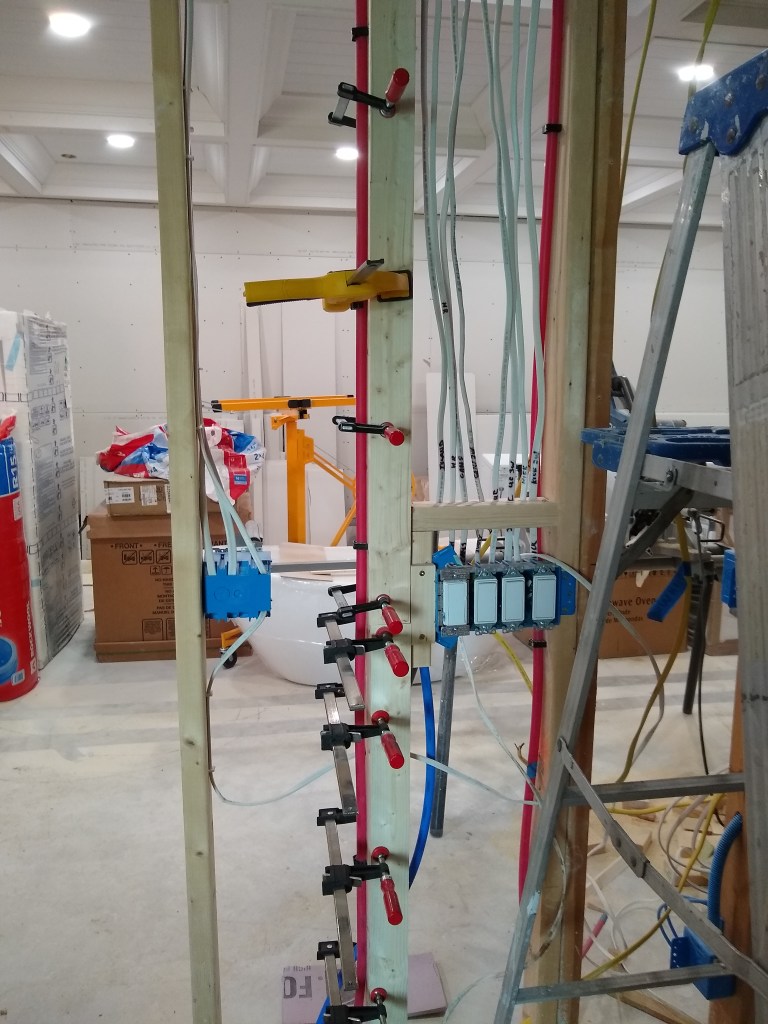

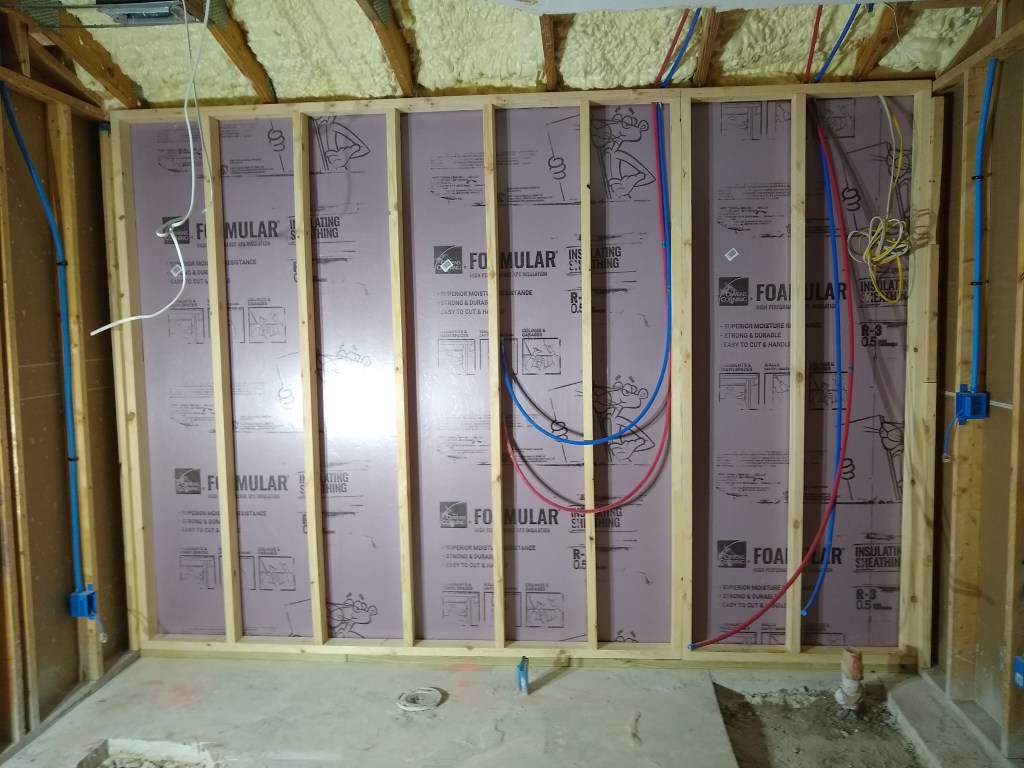

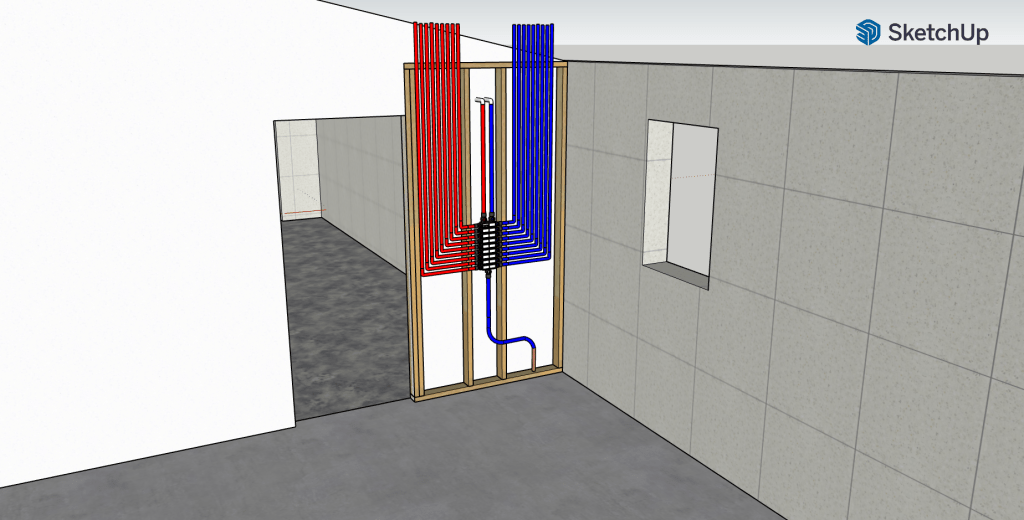

After that, I sorted out the services on the interior wall.

This short span of wall was retained as a place to mount switches (both great room and kitchen) and a place to route the water and electrical lines to the island. In the original plan, I had a 4-gang box: one for a light above the old island location, a second for the can lights in the ceiling, a third for the under counter lights, and a fourth for the kick plate lights. In the new plan, there is no need for separate island lighting. Consequently, the 4-gang box is replaced with a 3-gang box. Beside it is a blue 1-gang box that will house the only Ethernet connection within the kitchen. Below the 3-gang box is another 1-gang box for the GFI outlet (12/2 wire – yellow). This outlet was originally at counter top height, so the wire was not quite long enough to reach to where you would normally put an outlet box (about a foot above the floor), so I raised it up a bit to make it work. I don’t think it looks too odd. That box will also be where I splice in the GFI wire that will be routed under the slab to the island.

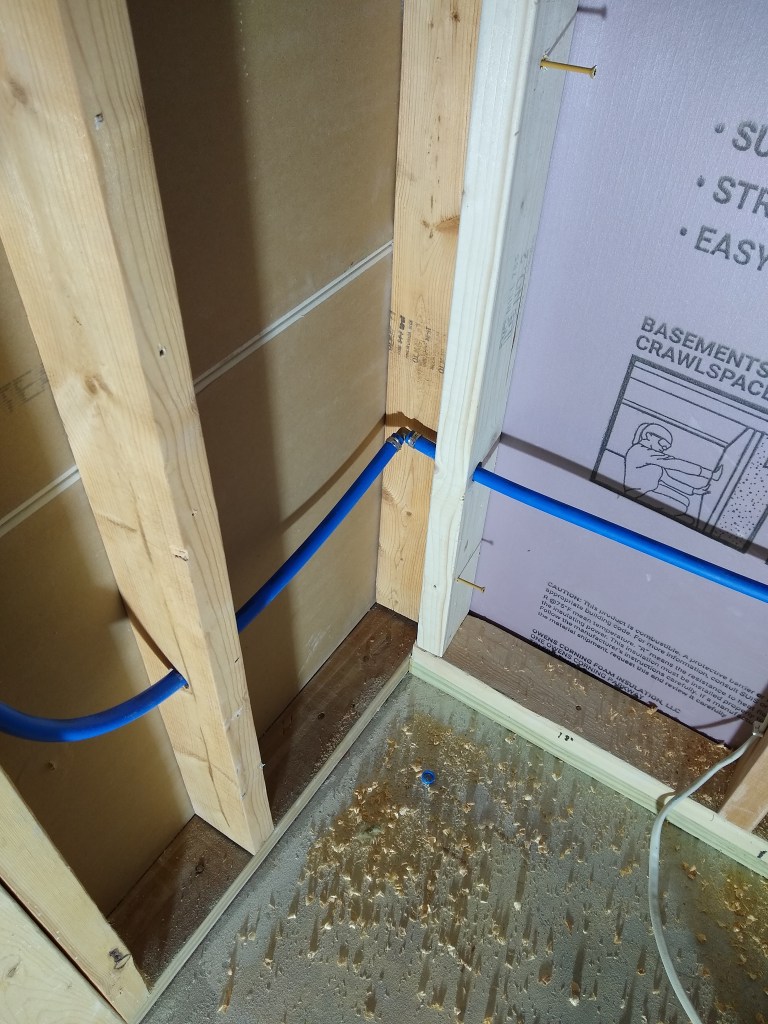

The blue and red water lines will also be routed under the slab to the island, along with a separate yellow wire for the dishwasher (separate circuit) and a white wire (14/2) from the 3-gang box to supply power to the kick plate lights there.

After finishing this work, I returned my attention to the master bathroom, where I began framing the toilet alcove (jump back to Master Bathroom – April 2023 to continue the story).

I have ordered a concrete saw in order to cut the new trench that will connect to the existing one. I considered renting a saw or hiring this work out, but after exploring the purchase route, I felt the cost was reasonable and would give me more flexibility. Having my own saw will allow me to attack this without a rental clock running and is way cheaper than hiring it out. The saw is not limited to just cutting concrete, so I’ll have use for it in the future. It will show up in the next post. That’s all for this one.