Flooring Continued, Kitchen Electrical Work, and Painting the Master Bedroom – March 2025

At the end of the last post, the flooring installation was paused as I waited for the extra material to arrive so they could finish the job. Before that, they finished the master bedroom, which took two days, and then started on the office. I forgot to show a picture of the master bedroom before the pause, so here it is now.

In the image above, notice how on the wall near the window I used two different primers, hence the color difference. I mention this because later I will show the bedroom after I painted it and it is hard to distinguish between the primer and the paint. This was just to provide evidence that the room wasn’t painted before the flooring was installed.

While I was waiting for the additional flooring to arrive, I started cleaning up and organizing the place. Now that most of the flooring was in, I could begin dusting the contents that had been moved out of the bedrooms into the great room. Most things were caked with dust from the many drywall sandings that had taken place. Since that part of the renovation was behind me, dusting the furniture and other items was no longer pointless. It would be nice to work in a relatively clean environment for a change. Also, since I had the time, I cleared the workshop of its contents and scraped the floor in preparation for the return of the installers.

Once the wood arrived, I notified the installers and they showed up a couple of days later to finish the office and workshop.

Notice how there is a bit of variation in the wood. The left side was done using the original order, and from about the middle of the room toward the right is where the newer flooring was introduced. This is even more evident when you look at the workshop, which was the last room they did.

The flooring in these two rooms is far more patchy than the rest of the house. This possibility was taken into account when it became clear that additional flooring would be needed, which is why I asked them to use the remaining material in the master bedroom. Under normal circumstances they would have continued from the guest bedroom and hallway into the office and then the workshop, finishing up in the master bedroom. Knowing that the new material may vary somewhat from the original, if there was going to be any variation, I wanted it to be in these two rooms.

With the flooring installed, I could start to move the things I had dusted back into the rooms, where they would remain dust free, apart from the usual dust one gets.

In the workshop, I decided to re-purpose the cabinet that was supposed to be placed on the far side of the refrigerator. Unfortunately, I miscalculated the room I had along the east wall of the kitchen, and this nice little cabinet would not fit. So here is its new home.

In the kitchen, this would have been great for spices, but here it will serve nicely as a place to store glues, finishes, and maybe screws and other fasteners.

Wiring the kitchen island was my next priority. After completing this I would be able to request another inspection to trigger an extension of my permit expiration date.

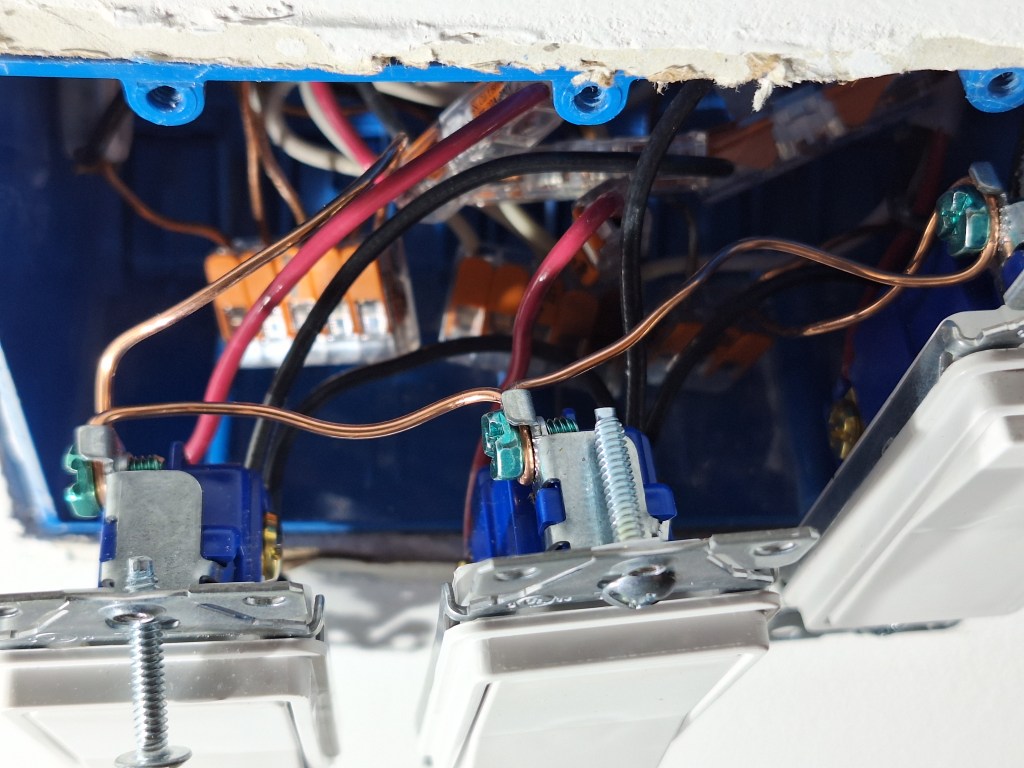

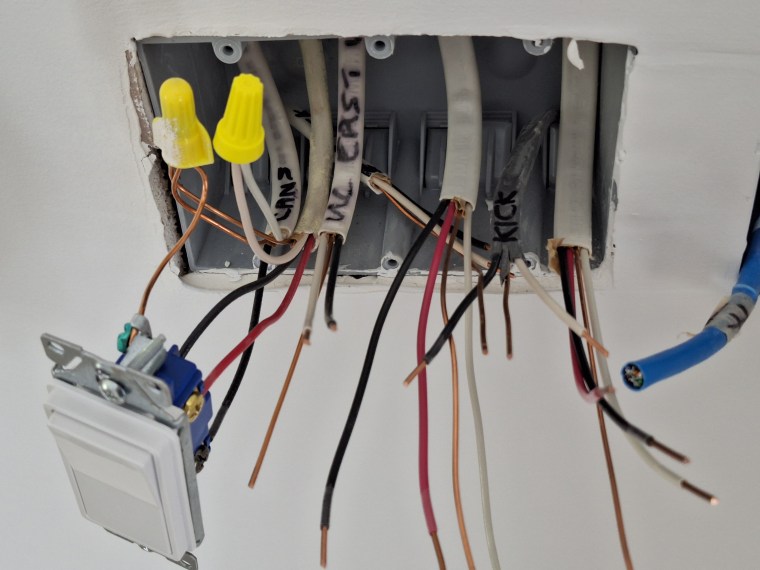

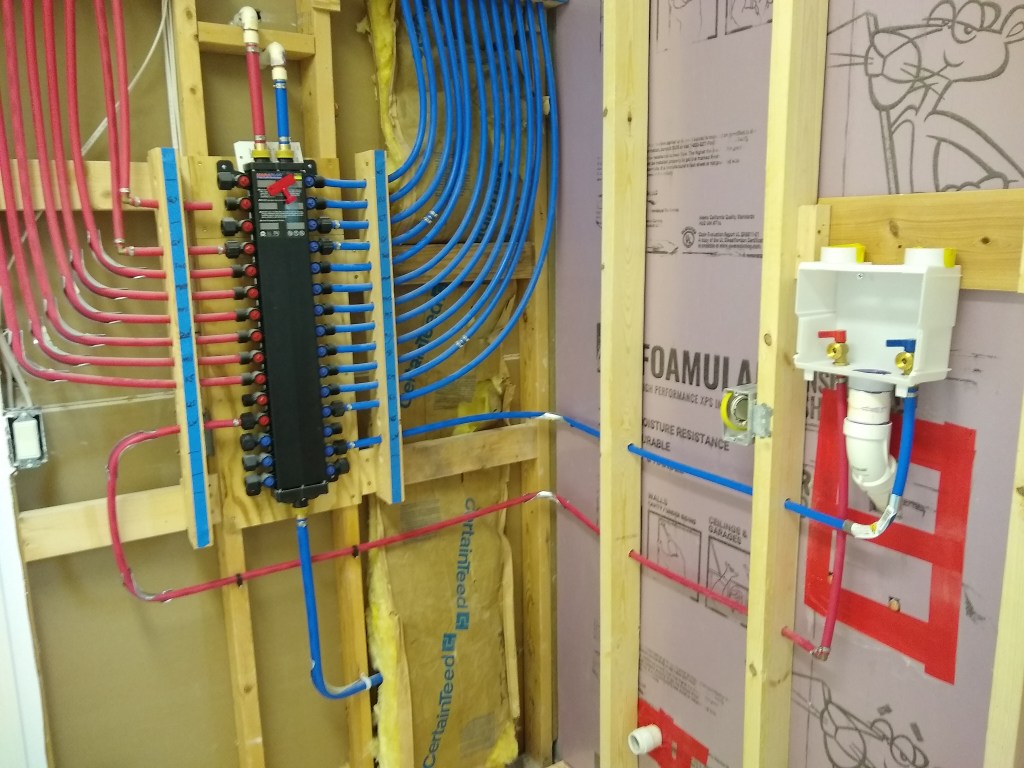

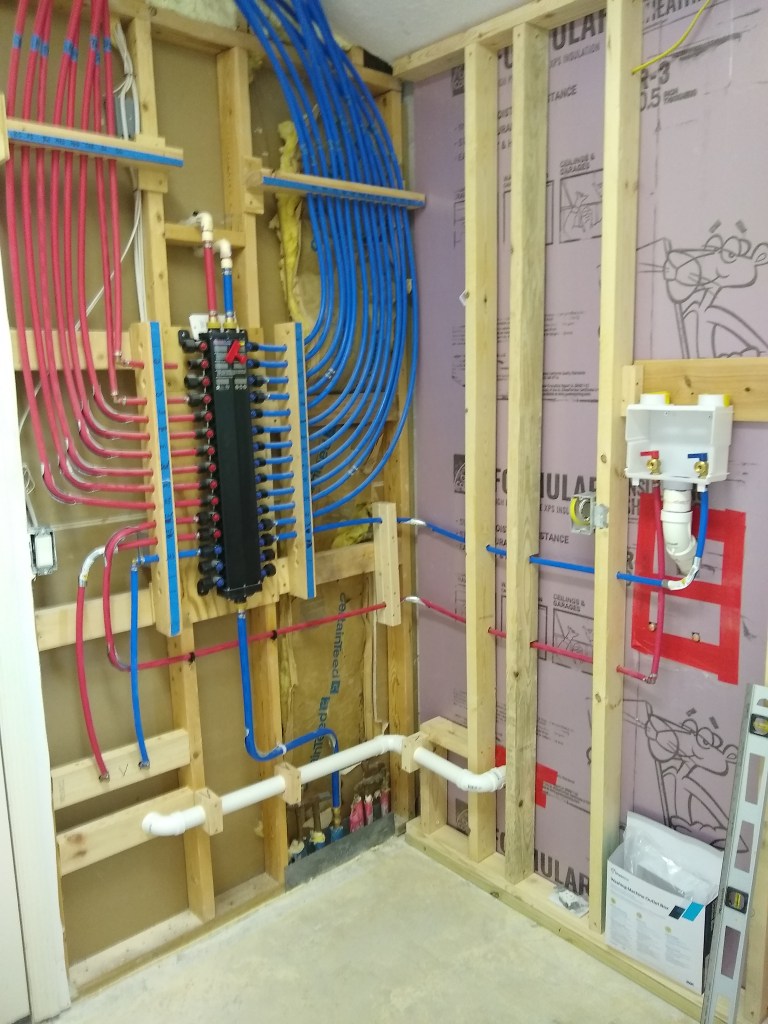

The island has three lines coming into it from under the slab. In the picture below, the wire on the left is tied to the general 15 amp circuit for the kitchen, and will be used for kick lighting. The one in the middle is for the 20 amp GFCI outlets. The one on the right is on a dedicated 20 amp circuit for the dishwasher.

Because these wires are located inside cabinets, they will be subject to damage as items will be moved in and out of them. Consequently, they need to be protected. This is done by using Metal Cased (MC) cable, instead of the usual Romex that is run behind the walls.

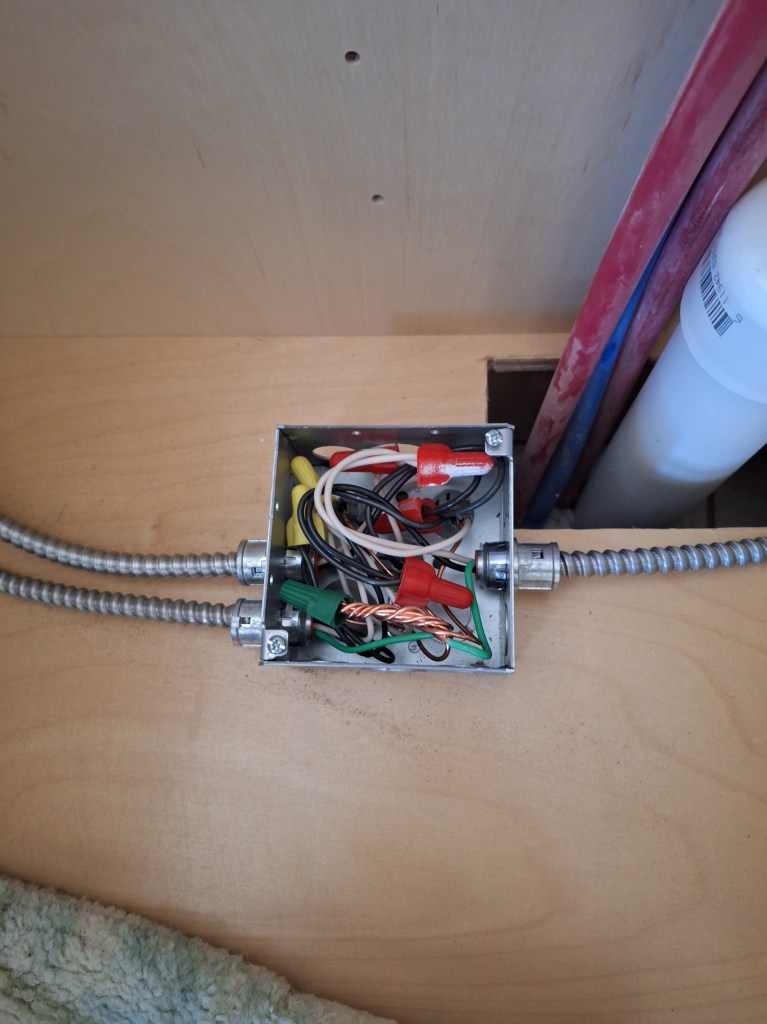

The outlet on the far left is where the power adapter for the kick lighting will plug into. The one just above it is the GFCI outlet. The in-sink garbage disposal will plug into this. It branches out on either side to the two ends of the island where counter top pop-up outlets will connect. The outlet on the right is where the dishwasher will connect. The inside of the junction box on the bottom of the cabinet looks like this inside:

Below I provide a series of pics to show how it all fits together.

An MC cable extends from the outlet shown above heading south behind where the dishwasher will go and into the sink base cabinet, connecting to the GFCI wire inside the outlet box, shown below.

At the other side of the GFCI outlet, another MC cable extends southward behind the cabinet where the garbage pales reside.

This cable terminates at the second outlet that is in the south end cabinet. It will provide power for another set of counter top pop-up outlets.

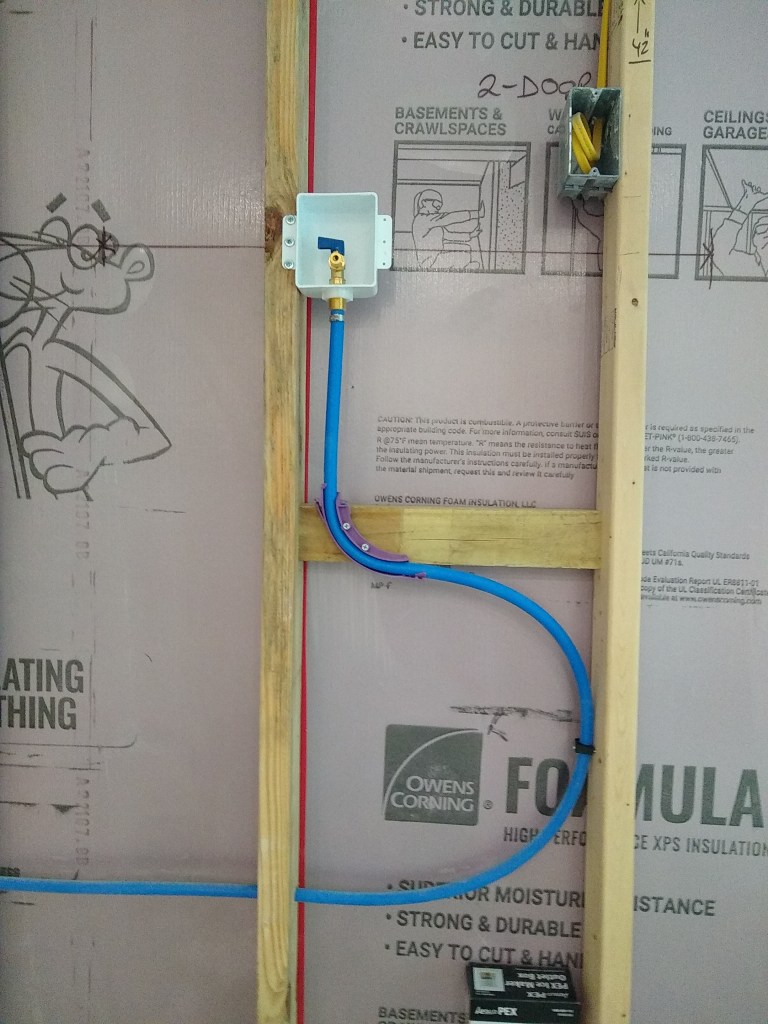

I also installed an outlet at the bottom of the pantry for the kick lighting along the east wall of cabinets.

The inspection was performed shortly after, and it was successful. Thus, my permit expiration date is now extended to September.

Since the ends of the island cabinets do not match the color of the cabinets, a 4’x8′ sheet of 1/4″ material is provided so that it can cover those areas. So I cut and shaped it and attached it to both ends. Here is one of the ends.

That looks much better. I’ll do the same for the kicks, but only after I understand how I will run the lighting for that area.

I spent some time researching how to install the kick lighting. After feeling like I understood it and deciding on the approach I would take, I ordered the various pieces. That would take some time to arrive, so I decided to clear out the contents of the great room, which had been holding the contents of the various bedrooms while the flooring was being installed. It was nice to clear that area. With the flooring in and the great room mostly cleared, it made the place look less like a constructions site.

I have a number of items I no longer need and will attempt to sell. I’ve temporarily stored them in the dining room area. The keen observer will notice that I installed the ceiling fan, too. That’s the original one. I think it looks pretty good, so I might just leave it. It will depend on how I intend to decorate the place, which will be a very long way off.

While still waiting for the kick lighting parts to arrive, I painted the master bedroom. The final room to be painted. The ceiling in that room was painted long ago, but the walls had only been primed, so I would give it two coats of the same paint I used for the great room.

I hope you noticed the new fan/light I installed. I was going to install the original fan, which didn’t have a light. I wanted to have an overhead light in this room, so I opted for this. I really like it. It is controlled by a remote control, which allows me to vary the fan speed and dim the light. Very nice! I may replace the others with this style, but that is a very low priority so it won’t happen anytime soon.

The parts for the kick lighting arrived around the time I finished painting the master bedroom, so I got to work on that. The first thing I did, was install the kick plates. Below I am showing the back of the island from the north side. The gap between the cabinets is where the dishwasher will go. Keep this in mind as I discuss the sequence of runs of kick lights I will install.

Below I show the kick under the front of the island from the south end.

The kick lighting is controlled by a switched outlet under the sink. Since the LED lights require 12 volts DC, a power adapter (the black box) is required to convert from 120 volts AC to 12 volts DC. A controller (the little white box) is plugged into the power adapter to control the LED lights, which can produce a whole spectrum of colors. This controller is WiFi enabled, so at some point I will be able to modify the colors using an app on my phone. The power adapter and controller for the kick lights will be located in the sink cabinet, which is on the back side of the island to the left of where the dishwasher will go. I ran the wires from it to the front of the cabinet and down a hole I drilled to the kick area.

The brown wire that is connected to the controller interfaces with the LED strip under the kick, which I will show later.

The LED lights come in a roll and can be cut at designated areas where it can be terminated or connected to other runs. The light strips have an adhesive backing and are inserted into channels I attach to the underside of the kick space.

The light strip is covered by a diffuser, as shown below.

To support these channels, small clips are used.

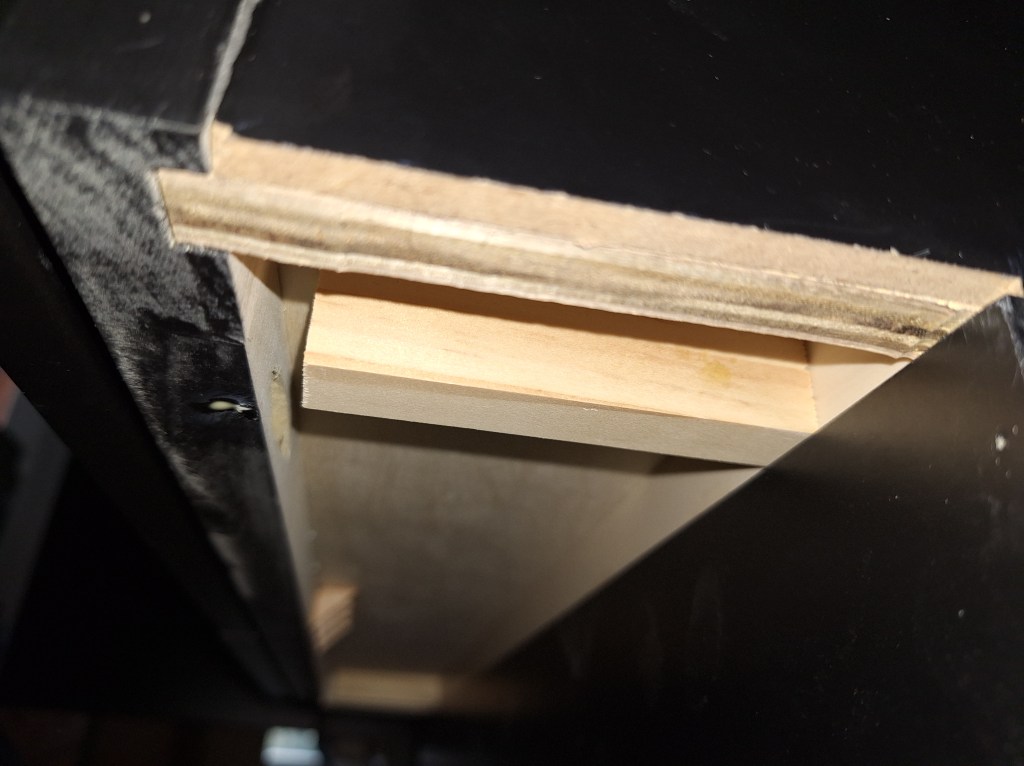

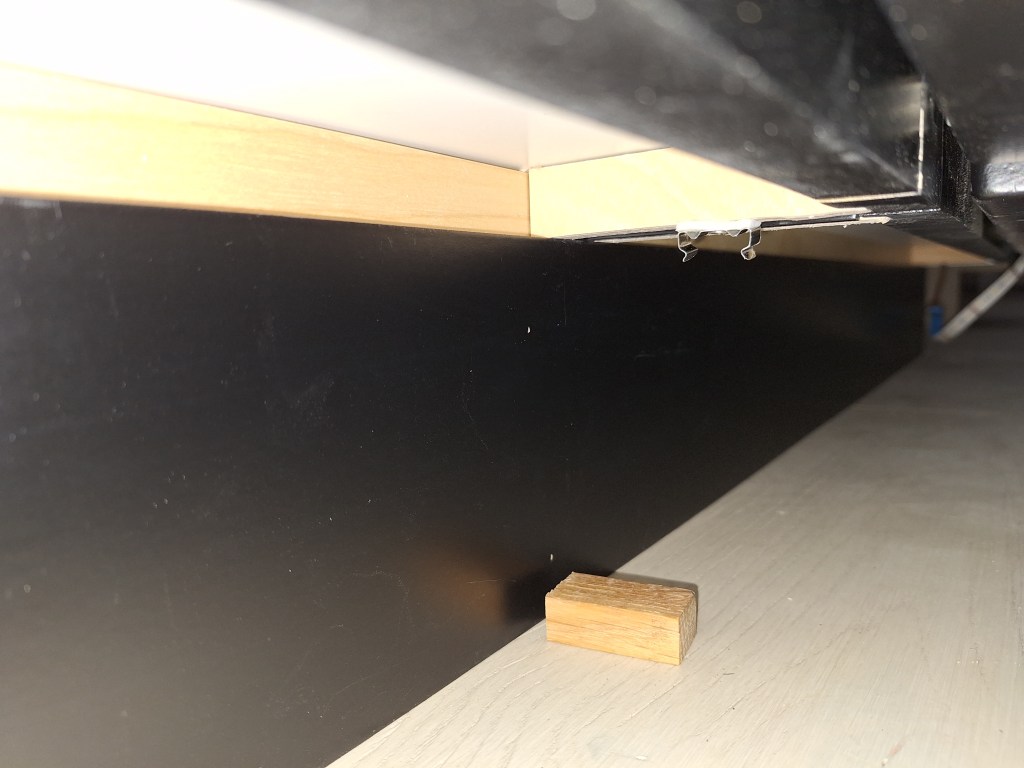

The mounting clips for the channel can be screwed into the bottom of the cabinet wall panels, but in order to hide the channels from sight when looking at the island from north and south ends, I added blocks a few inches in from each end.

I attached these small blocks using a combination of super glue and wood glue. The wood glue provides the strongest hold, but takes some time to cure. So I used the super glue to get an immediate hold, serving as a clamp, so to speak, as the wood glue cures. Six of these blocks were required in total. Below I show one of the clips attached. I used double sided tape to put it in place before securing it with a screw. The small piece of wood you see on the floor was used as a spacer to make sure each clip was positioned the same distance from the kick plate. It was a chore installing these things. I had to use a very short screwdriver as I lay on my side trying to work the screw into the wood.

Here is the channel in place.

And below is how the lights within the channel are connected to the controller under the sink.

To add the lighting I wanted around the island would require three separate runs, each connected by wires I would feed through the cabinets connecting the runs on the back of the island to the front. The first run would start from the sink cabinet and terminate at the south end of the island. The second run would pick up from the first at the south end of the island, but on the other/front side (facing the great room) and run the entire span of the island. Below I show the wire that is connected to the end of the first run and through the back of the end cabinet.

It emerges at the back of the end cabinet at the front of the island, where it dives down into the kick area underneath and is connected to the second run in the same way the first run was connected to the controller (shown above).

The third run would be a short one, starting on the north end and terminating where the dishwasher will go. The second run is connected to the third run in the same way we connected the first and second runs. Essentially, I am wrapping around the island from one side of the dishwasher and terminating on the other side of the dishwasher.

Here are the various runs illuminated.

I think this looks pretty good. I still have some work to do to secure and protect the wiring in the cabinets. I have some ideas about how to do that, but will get to it when it suits me. Next I tackled the kick lighting under the white cabinets.

The kick lighting for the cabinets along the east wall of the kitchen was much simpler, as it consisted of only a single straight run. The power adapter and controller were placed at the bottom of the pantry cabinet.

Here is the final result.

During this time, I ordered another cabinet that will go above the cook-top and support the exhaust fan. After some thought, that seemed to be the best approach, which I’ll discuss when I show it. I also ordered an additional refrigerator side panel since that nice little cabinet I put in the workshop would not fit. Those items are supposed to arrive in mid to late April. Once they are in, I can start to take steps toward getting the counter tops. More on that in the next post.