Kitchen, Garage, and other bits and pieces – May and June 2025

After a really nice week away, my first task upon returning to the house was to figure out how to hook up the vent hood. Just prior to leaving on vacation, I was speaking with a metal fabricator about creating custom piping to route the vent exhaust through the limited space in the cabinet above the cooktop. The situation is like this:

The hole in the bottom of the cabinet is 7″, and the one at the top is 6″. There is little space within the cabinet, so off-the-shelf parts would not fit. Hence, the need to speak to a fabricator. After that discussion I learned that it was going to be very expensive, so I started looking for alternatives. I found a short reducer online that would reduce the 7″ exhaust port of the vent hood to 6″ and take up minimal vertical space. A 90 degree elbow would then be needed to turn in the direction of the flex pipe. I ordered both, hoping they would work. They did not. So I found another metal fabricator that claimed they could do it for far less than the first one I contacted. So I handed the job off to them. The results of that will be presented in a subsequent post.

While attending to the exhaust venting, I used some of the wait time to add a switch and 4″ recessed light in the hallway between the master bedroom and bathroom.

Above the door to the bathroom will be glass, allowing the natural light from the sun tunnel in the bathroom to extend into the hallway. By adding a recessed light, there will be no fixture to obscure it.

My piano would be arriving soon, and it would be going in the dining room. Therefore, I needed to install a light fixture there before the presence of the piano got in the way.

I really like this fixture. I stayed with the matte black with white shade theme. Like the other fixtures, I will be keeping the cellophane on to protect the shade until I move in. Once installed, I cleared the area to make room for the piano, which arrived a few days later.

I subsequently purchase a new piano bench.

When ordering the light for the dining room, I also ordered a similar but smaller one for the laundry room.

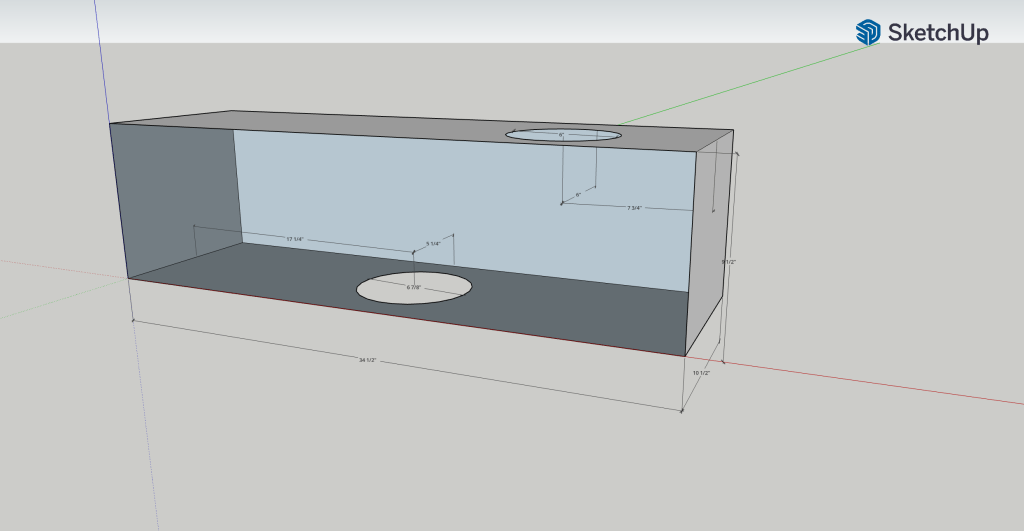

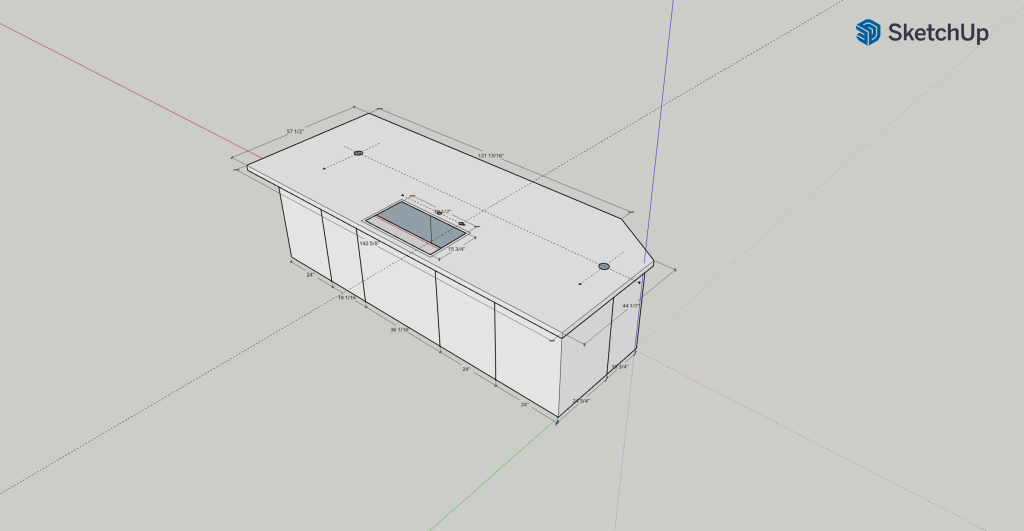

A lot of other work took place during this time. I ordered the items I’ll need for the kitchen island This included: the sink, faucet, popup outlets, and pressure switch for the garbage disposal. Those would be needed in order to know the cutouts required for the counter top. Once they arrived, I created the required sketches in SketchUp, which I’ll take to the company that will be doing the work. Here’s the one for the island.

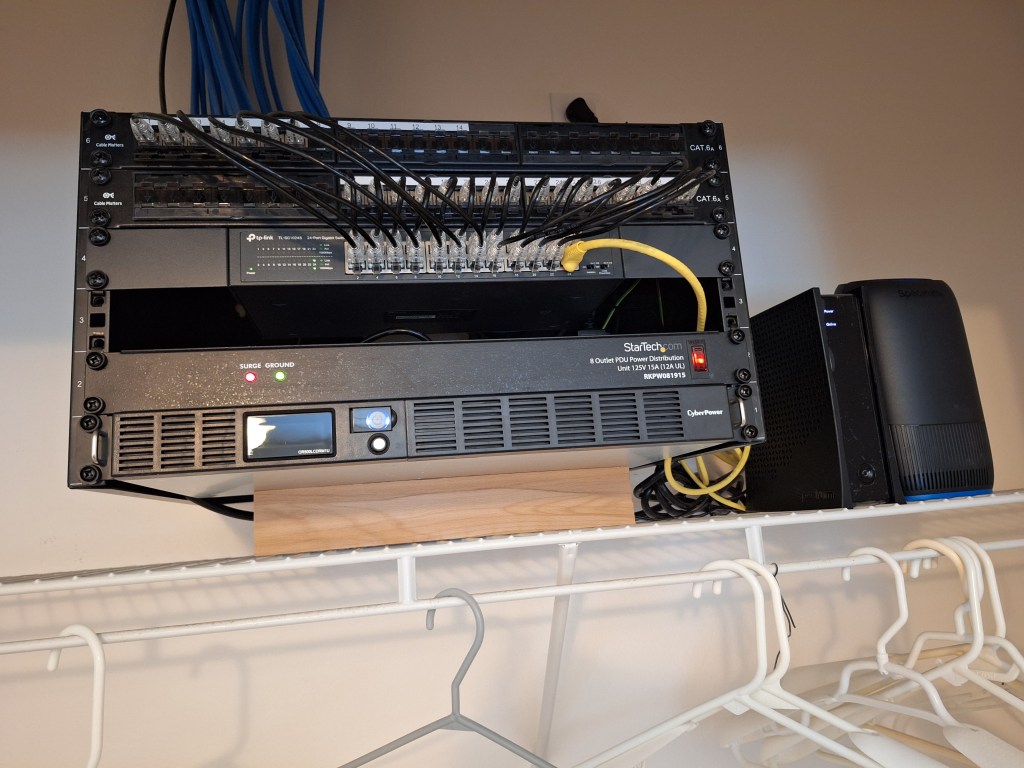

I also ordered the remaining equipment for the network rack, which included a UPS (uninterruptible power supply), a 24 port switch, and some other bits and pieces. The modem and router were supplied by my internet provider. Once they arrived and the cable guy activated the connection, here’s what I ended up with.

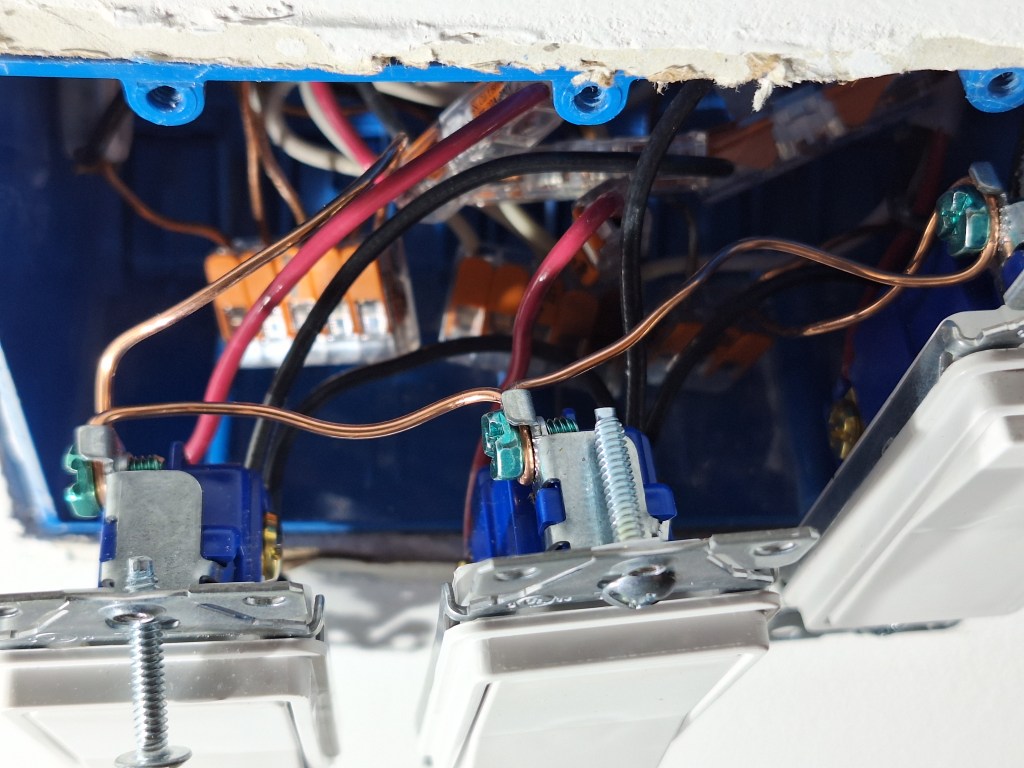

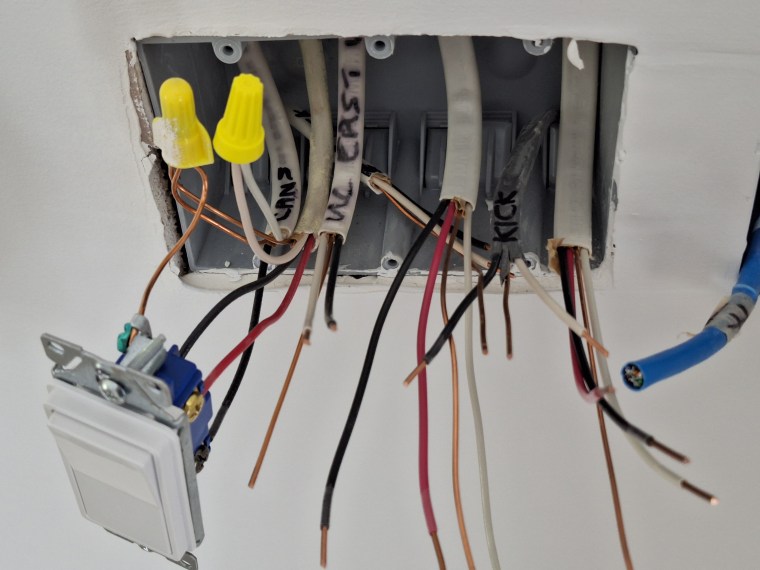

The top two slots contain patch panels. They are used to organize the 30 different cables I have running throughout the house, each terminating at a wall jack. In some places I have two jacks at one location. Here are a couple of examples.

Below the patch panel in the rack is a switch with 24 ports. Although I have more cables run than switch ports, in practice I will not use all available lines, so a 24 port switch is sufficient. If I need to use one that is not hooked up to the switch, it is easy to swap them around.

The router connects to the switch (the yellow cable), which will distribute the connection to the other ports and, ultimately, to the jacks through the patch panel. Below that I have a gap (unused slot) followed by a power strip. Below that is my uninterruptible power supply that plugs into the wall. All power goes through it, meaning all power in the rack is backed up by a battery and surge protected. The yellow cable connects the router to the switch, and the router is connected to the modem. As previously mentioned, the router and the modem were supplied by the service provider. It is nice to have internet access in the house again.

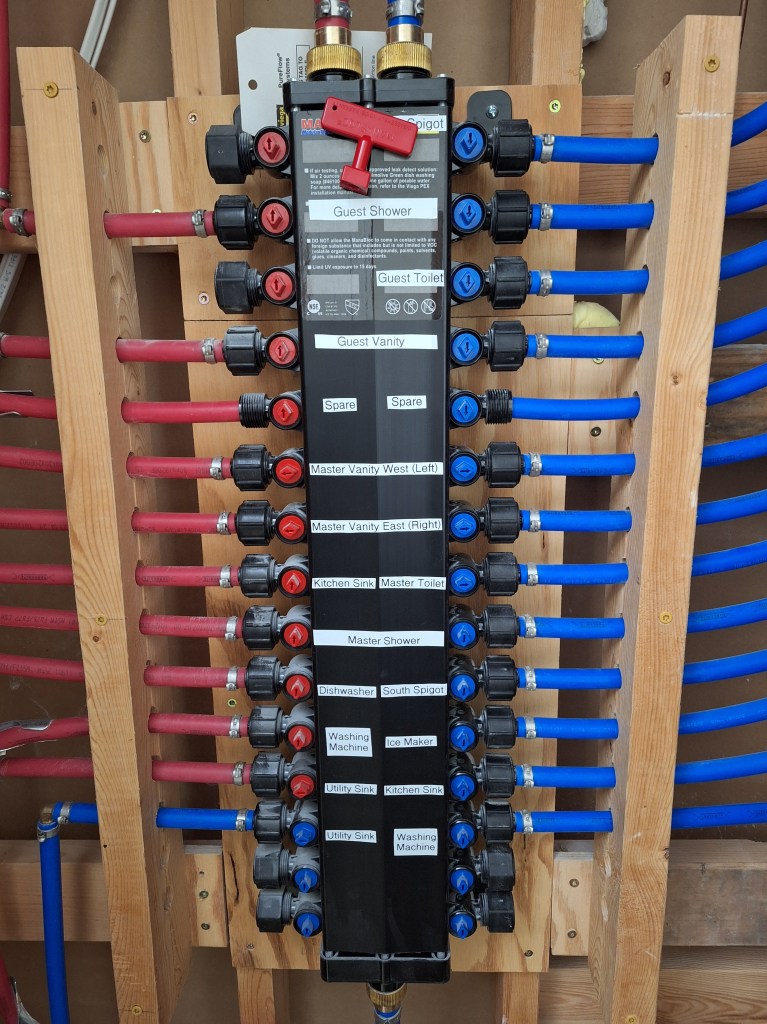

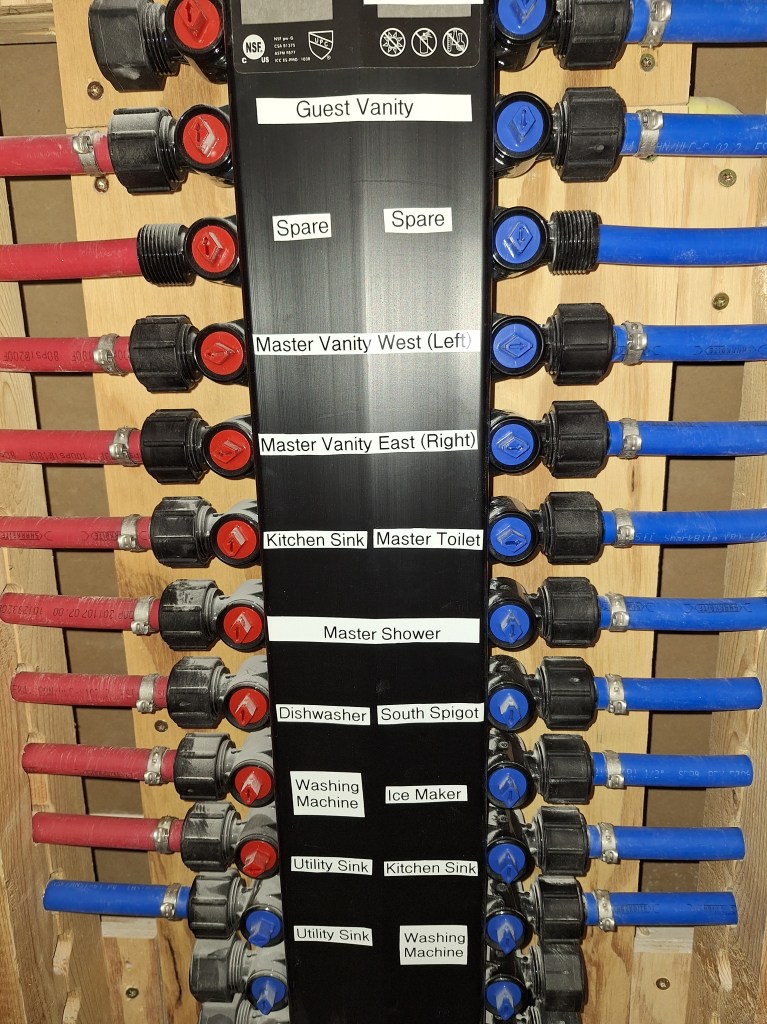

I purchased a nice little labeling machine. It will be used to identify the jacks. I also used it to label the water lines coming out of the Manabloc.

I will have lots of opportunity to use my nice little label maker elsewhere throughout the house.

Next, I went out to select slabs for the countertops. The process involves selecting the slabs, then arranging to have the fabricator receive them and take the measurements required to do the cutting and fitting. I identified a pair of book matched slabs for the island because one slab was not long enough to cover it. The cooktop area was much smaller, so one slab would provide far more material than I needed. The slab I am showing below is for the island. It is quartzite with only faint veining.

Unlike the island, the slab I selected for the cooktop area is granite, due to its ability to withstand heat better than quartzite. It is called Black Absolute and is shown below. The image below was taken at the fabricator because they just happened to have an off-cut of Black Absolute from another job that was the right size, so I didn’t have to buy a full slab for the relatively small area that needed it. Although it looks like there are some lines in it, there are not. Those are just streaks from the cutting process that dried.

After selecting the slabs, they would have to be delivered to the fabricator and then I would have to wait until they had time in their schedule to start cutting them. In the meantime, I attended to some other things I wanted to get done before the countertops were ready for installation.

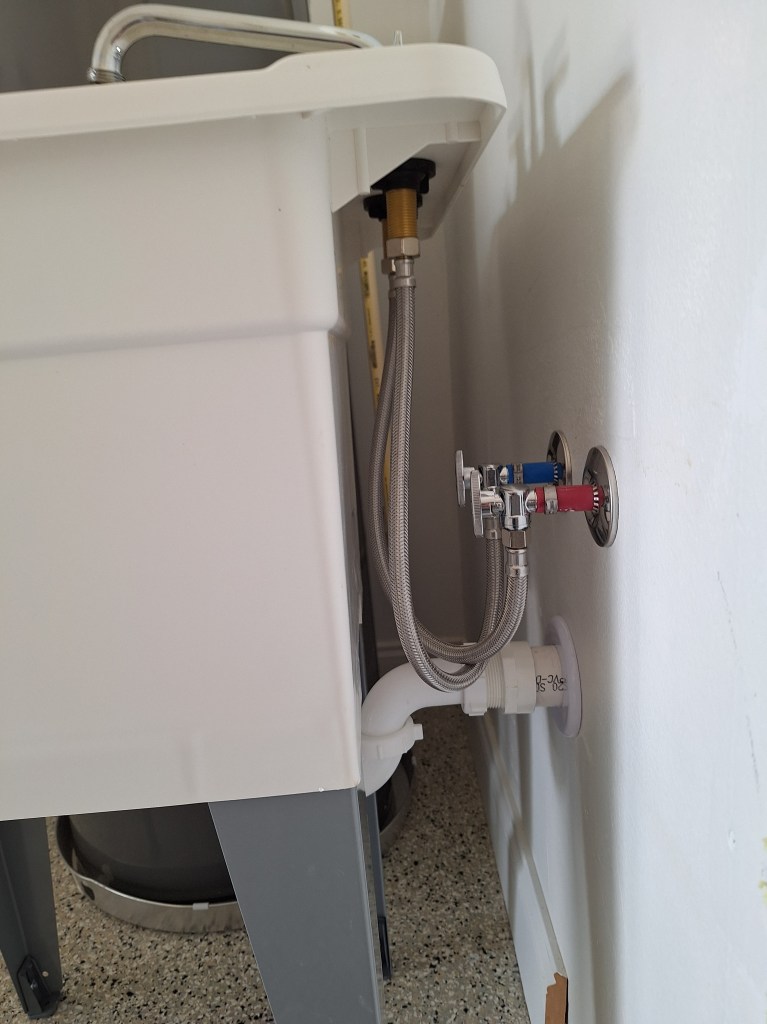

To cover and protect the some of the things at the bottom of the sink cabinet in the island, I built a box to enclose them. Here is what I was dealing with.

I wanted to create something that I could slide into place and cover the junction box, power adapter, and controller for the kick lighting, and surround the water supply lines and drain. Here is what I built.

There are various openings cut into the sides to make room for the wires and cables that enter/exit. The cutouts in the top are for the water supply lines and drain, and one for the wire to the junction box above it. Here it is installed within the sink cabinet.

This was made from some scrap pine I had, so it’s not too heavy, yet provides a solid enclosure. You just set it in place and slide it against the back of the cabinet to enclose the drain and water supply lines. It fits nicely in the space, covering exactly what I wanted. I will probably some Velcro to secure it to the back wall so I can easily remove it to gain access to the components within. I ended up increasing the width of the opening I made for the water supply lines because I needed to space them out more in order to secure them and make room for the straight stops I installed.

In the image above, I did not install the straight stop for the supply line to the dishwasher because I had yet to explore how to install the dishwasher, so I left it plugged and long.

The countertop process took longer than expected. This added a lot of down time to the renovation, and was the reason I did not finish this post in time to publish it at the end of May. I did not want to start a new project until after the kitchen was done, because none of the other projects would prevent me from moving into the house. Plus, I didn’t want to start something I might have to stop once I could move forward with the kitchen after the countertops were installed. Although not a prerequisite for moving into the house, while waiting I decided to start the process of getting the vanity mirror for the master bathroom. It will be one large mirror spanning the width of the vanity, so not something I could do myself. I had someone come out and measure and I subsequently ordered it. That too, would take some time, but another job initiated.

Eventually, I got fed up doing nothing and decided I had to start the next project. After the kitchen was done, I intended to turn my attention to the garage and setup a proper workshop, where I would be able to do the work needed to trim out the interior and, if adventurous enough, make the interior doors. This would be a big job, but one I could do in stages, so I decided to start by framing the west wall of the garage so I had a place to hang things and store long items. Here is what it looked like after I moved things out of the way.

And here it is after I framed it.

This is a twelve foot span. I did not take it all the way to the front wall of the garage because I thought I should leave some space because it can get a bit wet there if it rains. With this in place I added a high shelf from left over shelving from the closets inside the house, and several 1×6 horizontal boards to provide a place to attach various fixtures for hanging things.

I had a similar setup in my other house, and it worked well, so I decided to duplicate it here. The high shelf allows me to store very long things up out of the way. With the horizontal boards, I have the freedom to add or move fixtures as needed. Here’s what I’ve added so far.

It’s nice to have the yard care items off the floor. I’ve positioned them near the front of the garage. Near the back I have my desktop router table hung on the wall along with several extension cords. I will leave the space under them clear so that I can move equipment there, as you can see below.

This will remain a work in progress. I intend to acquire some new equipment and replace others to better assist me with my woodworking objectives, which will be captured in future blog posts.

After getting the wall up, I decided it was time to finish the butcher block countertop. So I pulled off the plastic wrap and moved it to an area where I could apply finish to all surfaces. Up until now, that butcher block countertop had be simply sitting, unattached and wrapped in plastic, on the base cabinets for a very long time.

I also picked up a 4′ piece of Butcher Block countertop and cut it into two pieces. One will sit on the 15″ base cabinet along the back wall of the garage, and the other on the 18″ base cabinet along that same wall.

I will be adding three or four coats of a clear polyurethane; as many as I can get out of the one quart can. Between each coat I lightly sand.

While I was “fabricating” the countertops for my garage cabinets, I paid a visit to the shop where my kitchen countertops would be cut to size. It was very nice of the guys to let me see how it’s done. When I asked if I could watch, I was expecting them to decline, but to my surprise they agreed. So here is what I saw.

Returning to my work in the garage, after adding all the finishing coats to the butcher block countertops, I was ready to attach them to the base cabinets.

Notice that I also added some open shelving above the 18″ base cabinet on the back wall. That was always my intention, but what was different was that I made use of some of the left over wire shelving I had stored away. It’s always nice to reuse things.

With all the waiting around that was required as I navigated the kitchen countertop journey, it was nice to be able to make progress in the garage, even though it was not required for moving in. Next week is the beginning of July and I am expecting the kitchen countertops to be installed. That will make for an interesting post. Until then…